General suspended automobile drive axle balance shaft on-vehicle repair machine

A drive axle and suspension type technology is applied in the field of general-purpose suspension type vehicle drive axle balance shaft repairing machines, which can solve the problems of high consumption of labor hours and high prices of consumable parts.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

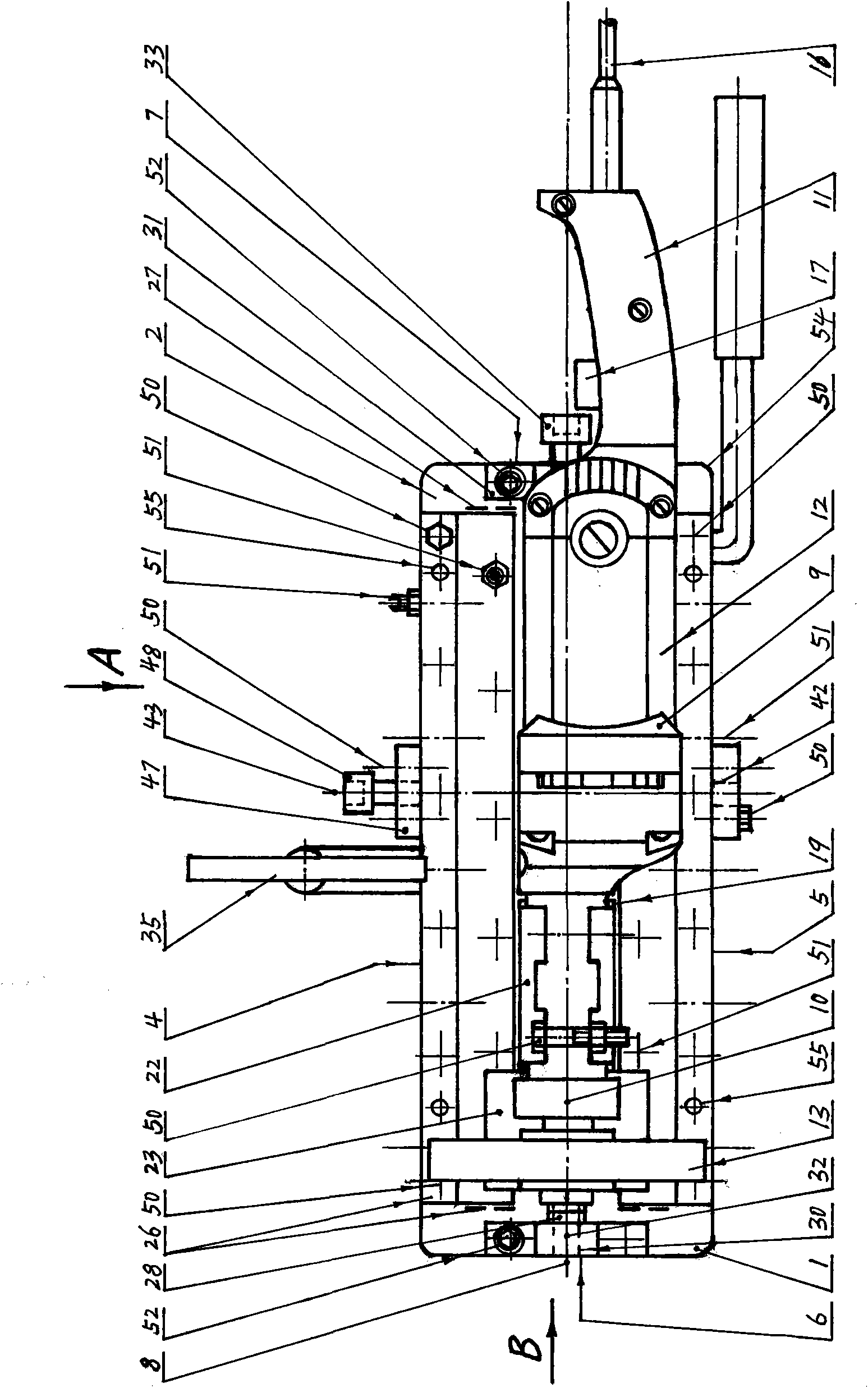

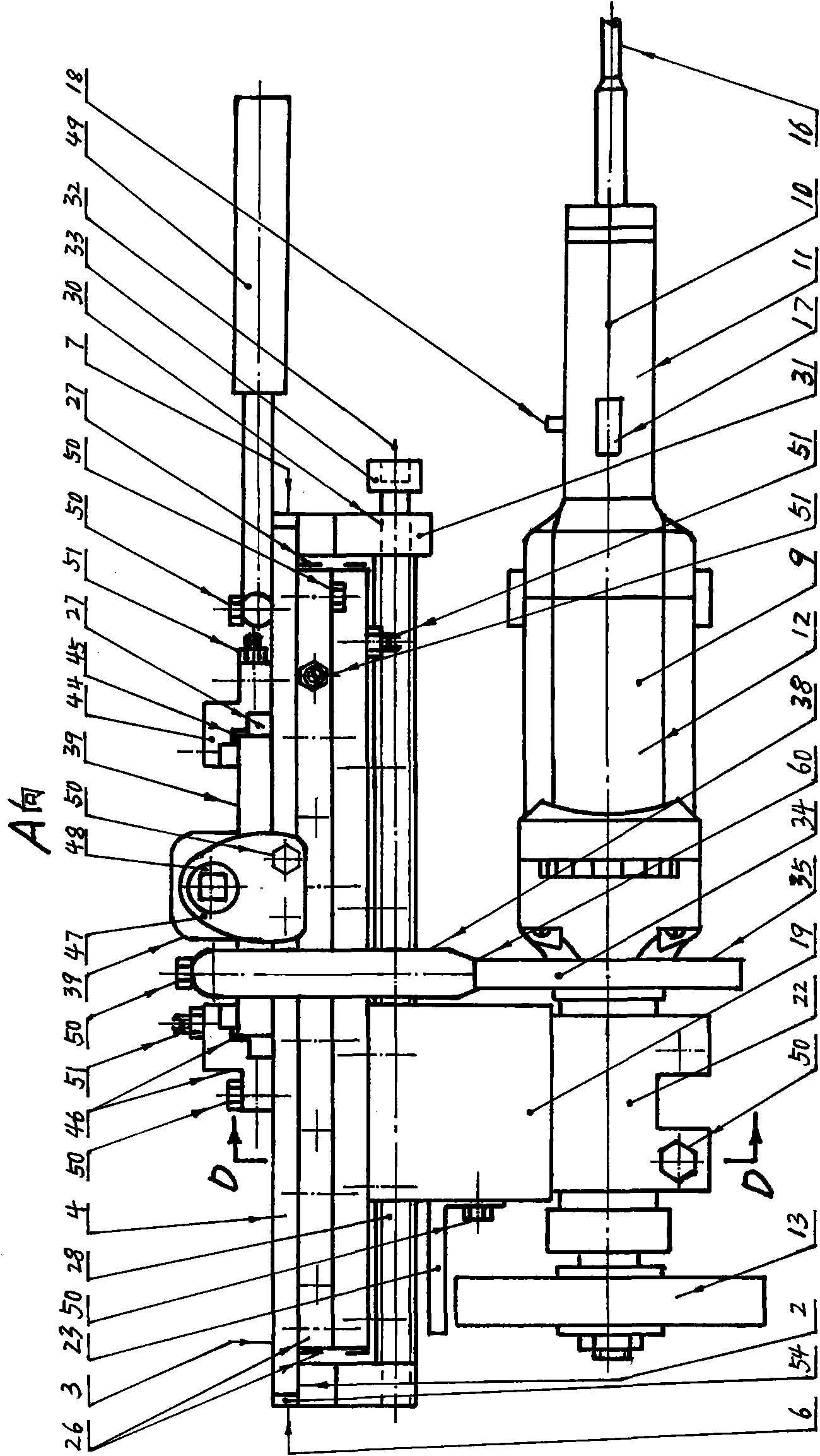

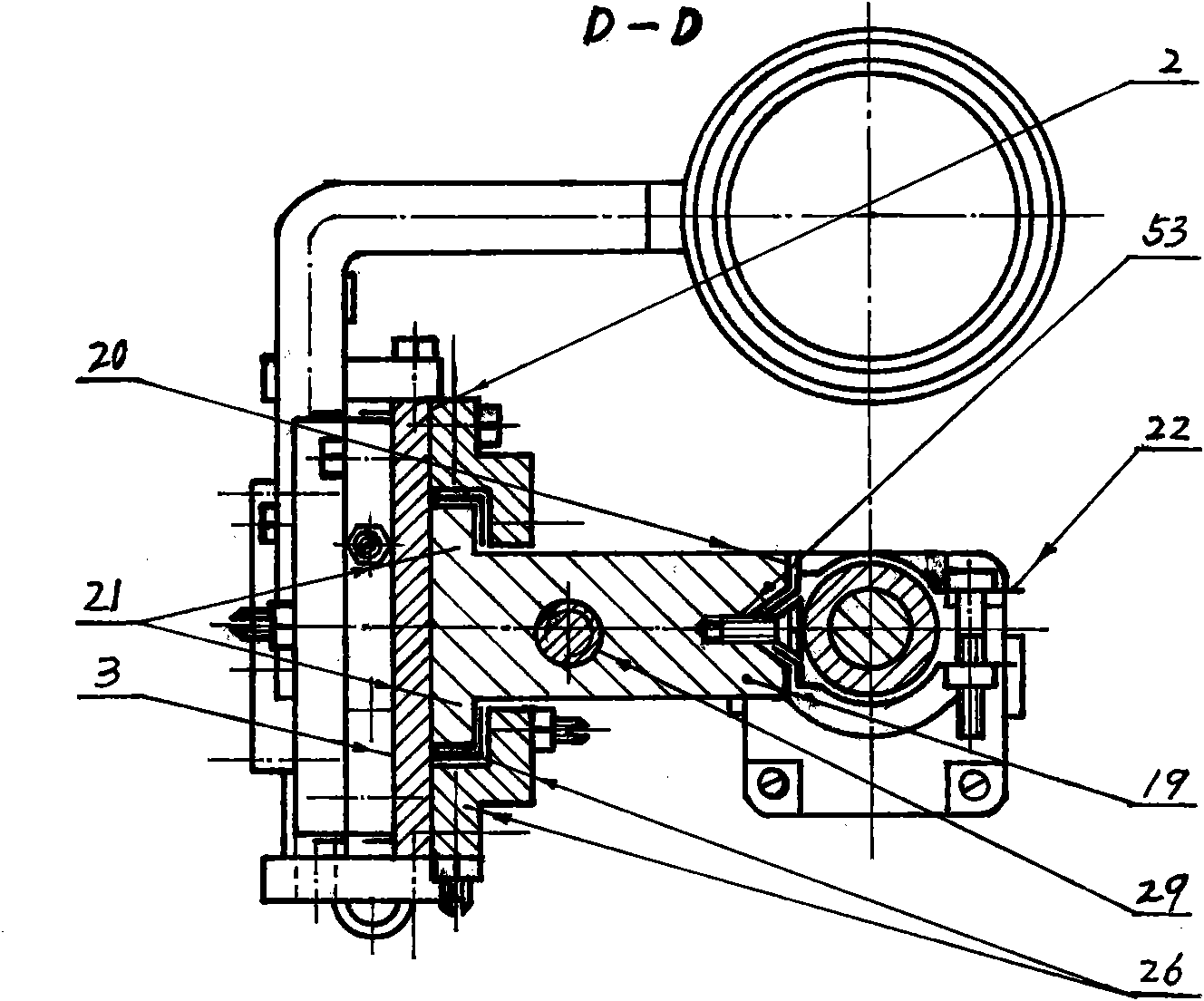

[0034] From Figure 1-1 to Figure 4 As can be seen from the series of drawings of the present invention, the general-purpose suspended automobile drive axle balance shaft repairing machine of the present invention uses a cuboid plate as the main frame (1) on the machine host of the present invention, and on the main frame a surface (2) Be provided with main grinding tool (9) and main grinding tool longitudinal manipulator, be provided with suspension steering arm (34) and main mill lateral manipulating device and main engine steering handle (49) on main frame b surface (3). Equip one group of annex to turn to combined bearing (57), the conversion bushing (61,62) that two pieces of specifications are different, a ratchet handle wrench and random tool three-piece set and supporting use with the main frame of machine of the present invention.

[0035] From Picture 1-1 middle, Figure 1-2 middle, Figure 1-4 in and Figure 1-5 As can be seen from the figure, the main frame (1)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com