A plasma display barrier repairing slurry and a repairing method thereof

A plasma display and barrier technology, which is applied in the field of barrier barrier manufacturing materials and processing technology, can solve the problems of low efficiency, cumbersome barrier defect repair process, and difficult operation by personnel, and achieve low melting point, good mass production feasibility, and glass adhesion. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

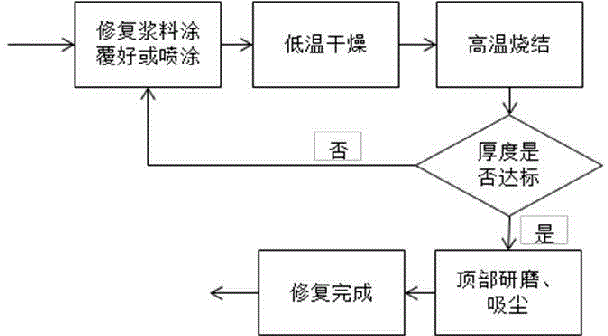

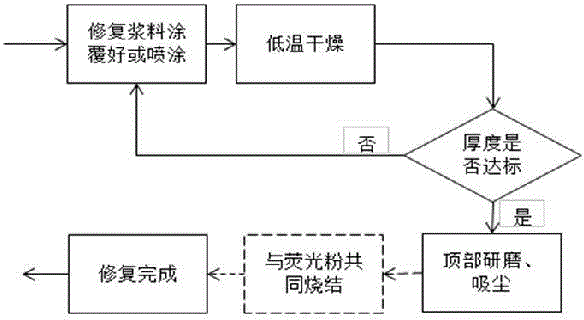

Method used

Image

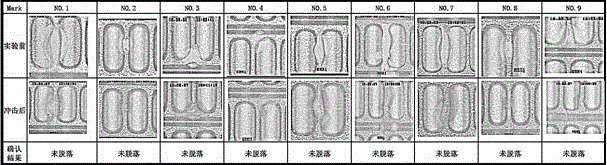

Examples

Embodiment 1

[0043] Firstly, 68% Bi 2 o 3 , 13% Al 2 o 3 , 7% ZnO, 9% B 2 o 3 , 3% SiO 2Uniformly mix to obtain the inorganic glass powder system; then by mass percentage 41% solvent diethylene glycol butyl ether acetate, 40% solvent terpineol, 12% polymer ethyl cellulose, 6.5% plasticizer o-phthalic acid Dibutyl diformate and 0.5% additive oleic acid are uniformly mixed to obtain an organic system; finally, the glass powder system with a mass percentage of 82% and the organic system are 18% uniformly stirred and mixed, ground and dispersed, and finally filtered through a filter device to be repaired The slurry is stored in a container for use.

[0044] Place the rear glass substrate of the plasma display screen with the graphics of the addressing electrodes, the rear dielectric layer, and the barrier ribs facing up and place it horizontally on the repair equipment machine.

[0045] Use a repairing needle or an injection device to apply the repairing material in the container to the...

Embodiment 2

[0062] Firstly, 65% Bi 2 o 3 , 15% Al 2 o 3 , 8% ZnO, 8% B 2 o 3 , 4% SiO 2 Uniformly mixed to obtain the inorganic glass powder system; then by mass percentage 36% of the solvent diethylene glycol butyl ether acetate, 45% of the solvent terpineol, 9% of the polymer ethyl cellulose, 8% of the plasticizer phthalate Dibutyl diformate and 2% additive oleic acid are uniformly mixed to obtain an organic system; finally, the glass powder system with a mass percentage of 80% and 20% organic system are evenly stirred and mixed, ground and dispersed, and finally filtered through a filter device to be repaired The slurry is stored in a container until use.

[0063] Place the rear glass substrate of the plasma display screen with the graphics of the addressing electrodes, the rear dielectric layer, and the barrier ribs facing up and place it horizontally on the repair equipment machine.

[0064] Use a repair needle or injection device to apply the repair material in the container ...

Embodiment 3

[0068] Each component and the mass percentage of each component in the glass powder system are: 67% Bi 2 o 3 , 15% Al 2 o 3 , 8% ZnO, 7% B 2 o 3 , 3% SiO 2 ; Each component and the mass percentage of each component in the organic system are: 82% organic solvent, 8.5% polymer, 8% plasticizer, and 1.5% additive. Wherein, the solvent in the organic system is diethylene glycol butyl ether, the polymer is ethyl cellulose, the plasticizer is lauryl alcohol ester, and the additive is oleic acid. The 80% glass powder system and the 20% organic system are uniformly stirred and mixed, ground and dispersed according to the mass percentage.

[0069] Other parts are as in Example 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com