Positioning method of underground pipe non-excavation repair defect points

An underground pipeline and positioning method technology, applied in the direction of pipe elements, special pipes, pipes/pipe joints/pipe fittings, etc., can solve the problems of low efficiency, high cost, time-consuming, etc., to simplify the repair process, save time and frequency, and improve The effect of work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1a

[0046] A method for locating defects in underground pipelines without excavation repairing, comprising the following steps:

[0047] pipe cleaning

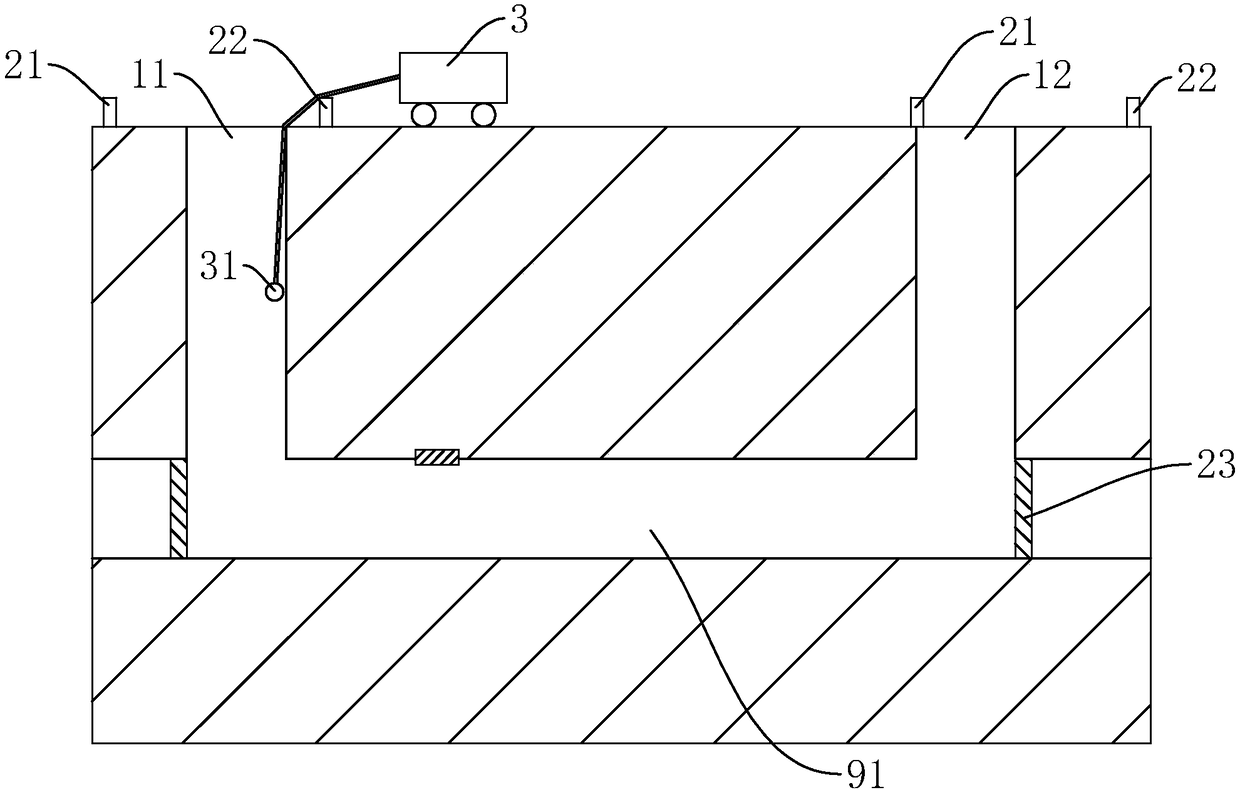

[0048] Step1.1, determine the underground pipeline 91 of the section that needs to be repaired, set up roadblocks 21 and warning signs 22 around the two drainage wells 1 that communicate with the underground pipeline 91 of this section, (for the convenience of expression, the two drainage wells 1 are named respectively below the first drainage well 11 and the second drainage well 12);

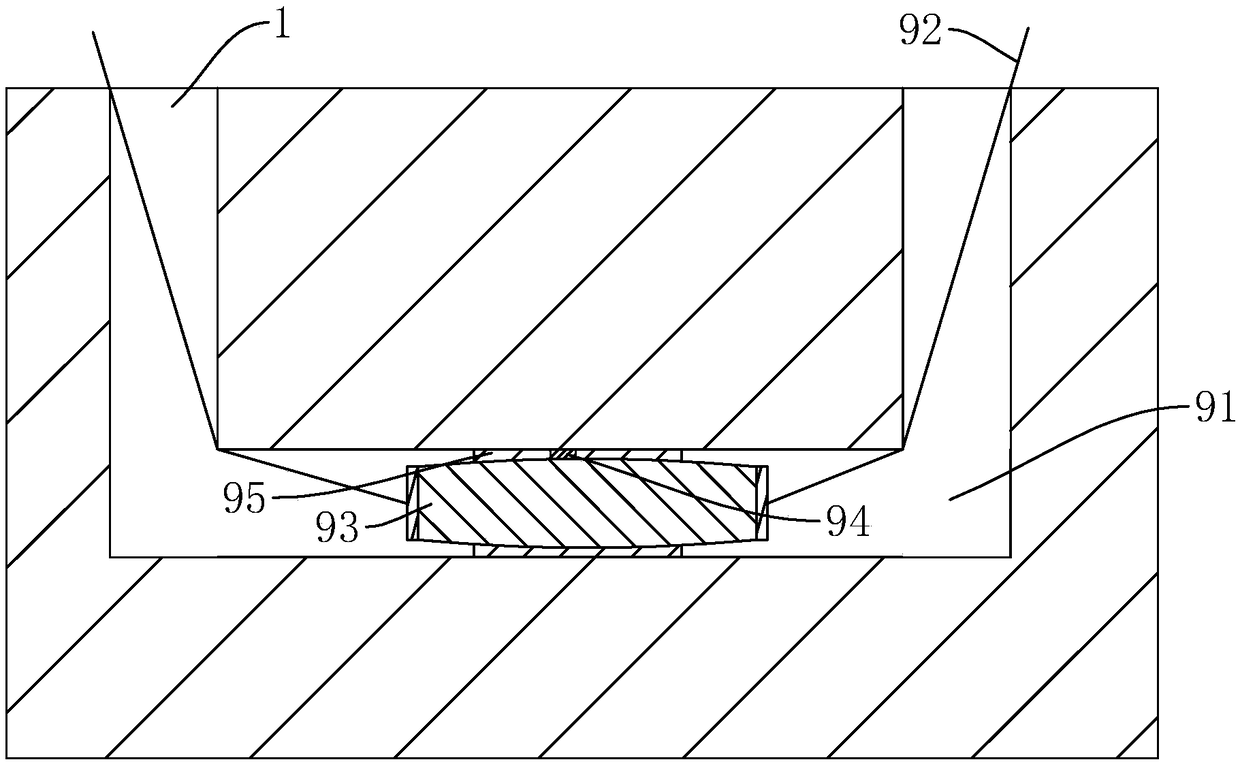

[0049] Step1.2, manually enter the first drainage well 11 and the second drainage well 12, and separate the underground pipeline 91 that needs to be repaired and the underground pipeline 91 that does not need to be repaired through the sealing plate 23 with the water hole;

[0050] Step1.3, the dredging vehicle 3 is parked near the first drainage well 11, the dredging nozzle 31 is sent into the pipe mouth of the underground pipeline 91 by the firs...

Embodiment 1b

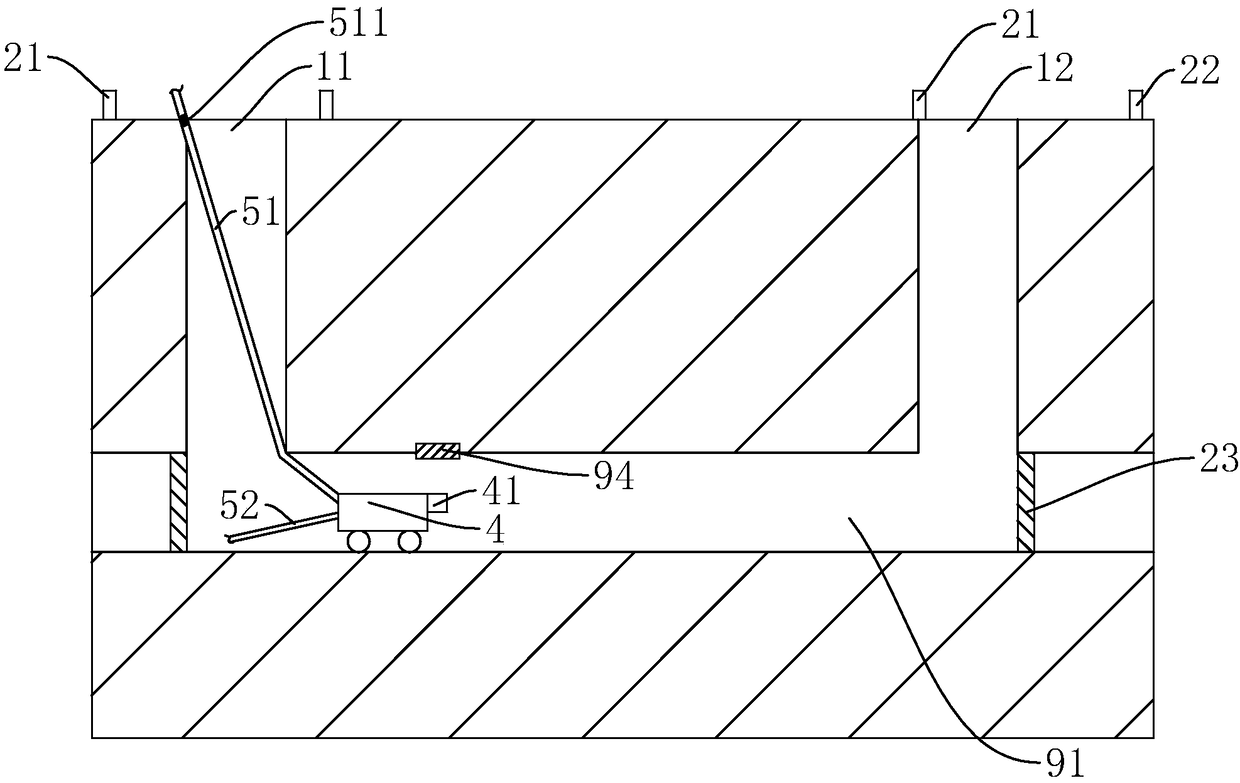

[0066] Embodiment 1b provides a positioning method for non-excavation repair defect points of underground pipelines. The difference between the embodiment 1b and the embodiment 1a lies only in the threading manner of the traction rope 52 .

[0067] Step1.4, repeat step1.3 for 1~3 times to complete the cleaning of the garbage inside the underground pipeline 91. During the last cleaning process, tie the traction rope 52 to the dredging nozzle 31, and drive the traction rope 52 through the dredging nozzle 31. located in the underground pipeline 91;

[0068] Step1.5 Untie the traction rope 52 and dredge the nozzle 91.

[0069] Step2.2 Send the remote control car 4 from the first drainage well 11 into the underground pipeline 91, control the remote control car 4 to walk inside the underground pipeline 91, and transmit the picture to the ground through the camera 41;

[0070] Step2.5 Repeat Step2.4 and Step2.5, determine the defect points 94 inside several pipelines on the connect...

Embodiment 2a

[0073] A method for locating defects in underground pipelines without excavation repairing, comprising the following steps:

[0074] pipe cleaning

[0075] Step1.1, determine the underground pipeline 91 of the section that needs to be repaired, set up roadblocks 21 and warning signs 22 around the two drainage wells 1 that communicate with the underground pipeline 91 of this section, (for the convenience of expression, the two drainage wells 1 are named respectively below the first drainage well 11 and the second drainage well 12);

[0076] Step1.2, manually enter the first drainage well 11 and the second drainage well 12, and separate the underground pipeline 91 that needs to be repaired and the underground pipeline 91 that does not need to be repaired through the sealing plate 23 with the water hole;

[0077] Step1.3, the dredging vehicle 3 is parked near the first drainage well 11, the dredging nozzle 31 is sent into the pipe mouth of the underground pipeline 91 by the firs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com