Contaminated soil in-situ remediation equipment

A technology for in-situ remediation of contaminated soil, applied in the field of remediation of contaminated soil, can solve the problems of not having the function of loosening and breaking soil, and achieve the effect of improving the remediation efficiency and simplifying the remediation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

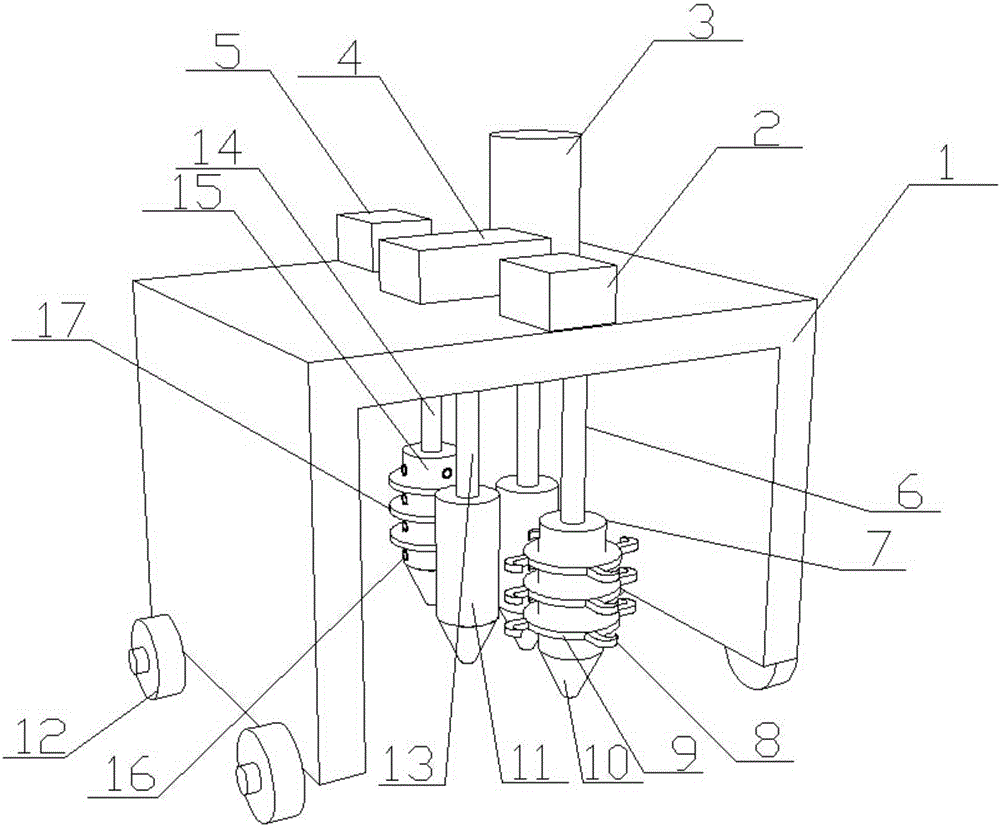

[0019] A device for in-situ restoration of polluted soil, comprising a walking frame 1, on which a rotatable soil loosening bar 7, a soil breaking bar 11 and a soil repairing bar 15 are sequentially arranged, the soil loosening bar 7, soil The broken bar 11 and the soil restoration bar 15 are respectively connected to the top of the walking frame 1 through the first telescopic rod 6, the second telescopic rod 13 and the third telescopic rod 14; rippers 8 are evenly distributed on the outer wall of the soil scarifying rod 7; The soil crushing rods 11 are two and distributed side by side, the soil crushing rods 11 rotate synchronously and in opposite directions, and there is a gap for soil to pass between the soil crushing rods 11; the soil restoration rod 15 and the third telescopic rod 14 are all hollow structures and communicate with each other. The soil repair rod 15 is provided with a chemical spraying hole 16 , and the top of the third telescopic rod 14 communicates with th...

Embodiment 2

[0022] Based on embodiment 1, the bottom of soil loosening rod 7, soil crushing rod 11 and soil repairing rod 15 are all connected with drill bit 10, and drill bit 10 helps to reduce soil loosening rod 7, soil crushing rod 11 and soil repairing rod 15 to enter the soil Resistance, improve work efficiency.

Embodiment 3

[0024] Based on Embodiments 1 and 2, the outer wall of the scarifying rod 7 is provided with a spirally distributed fixing ring 9 , and the scarifying device 8 is located on the fixing ring 9 . By setting the fixed ring 9, the ripper 8 is spirally distributed along the outer wall of the ripper bar 7 to ensure that the ripper 8 can fully excavate the soil during the rotation of the ripper bar 7 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com