Repair method of coal cutter planet carrier based on laser cladding welding

A technology of laser cladding and repair method, which is applied in laser welding equipment, welding equipment, coating, etc., can solve the problems of out-of-tolerance size of built-in parts, poor working conditions, and high use intensity, etc., and achieve low repair cost, Easy to operate and avoid secondary damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

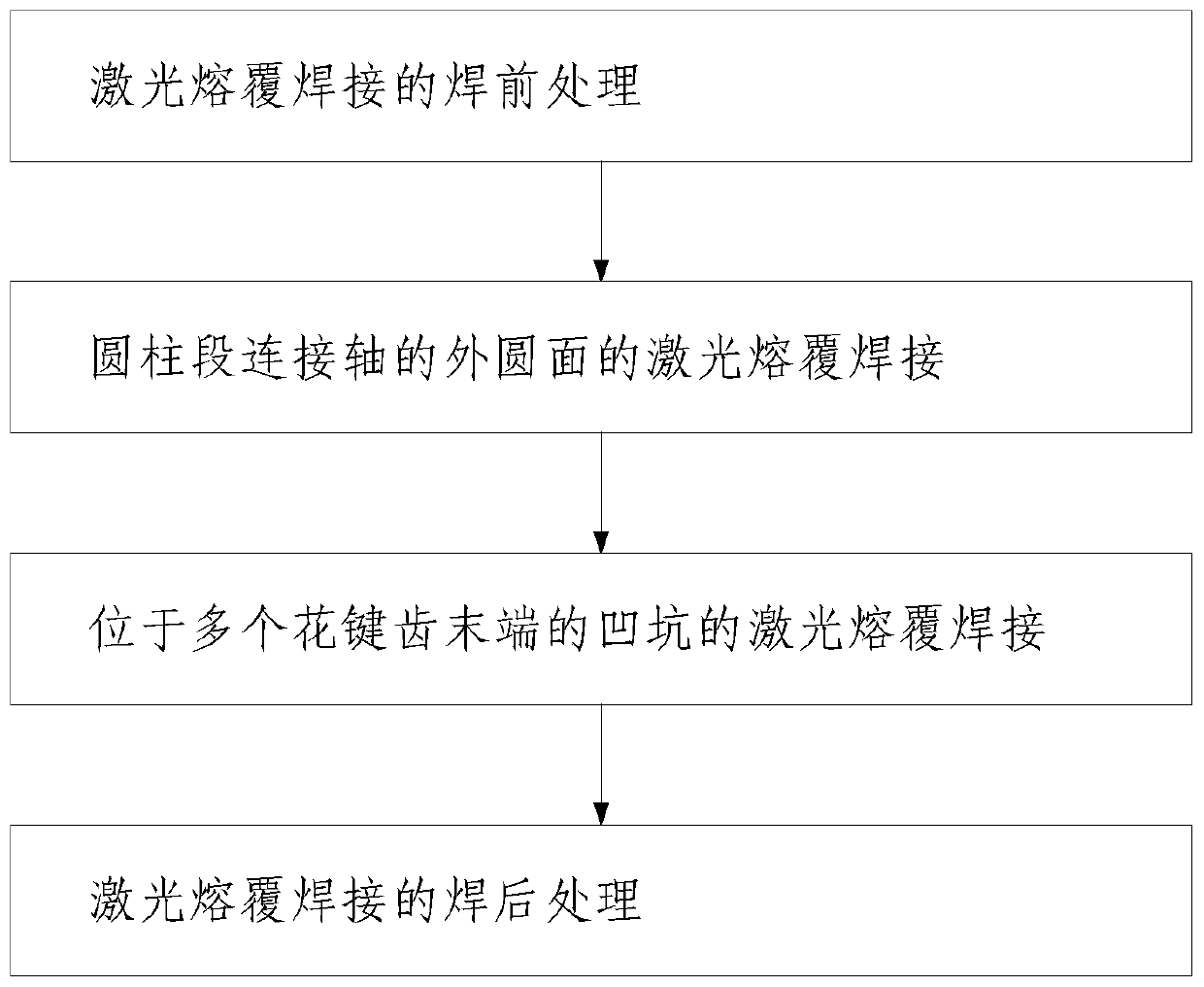

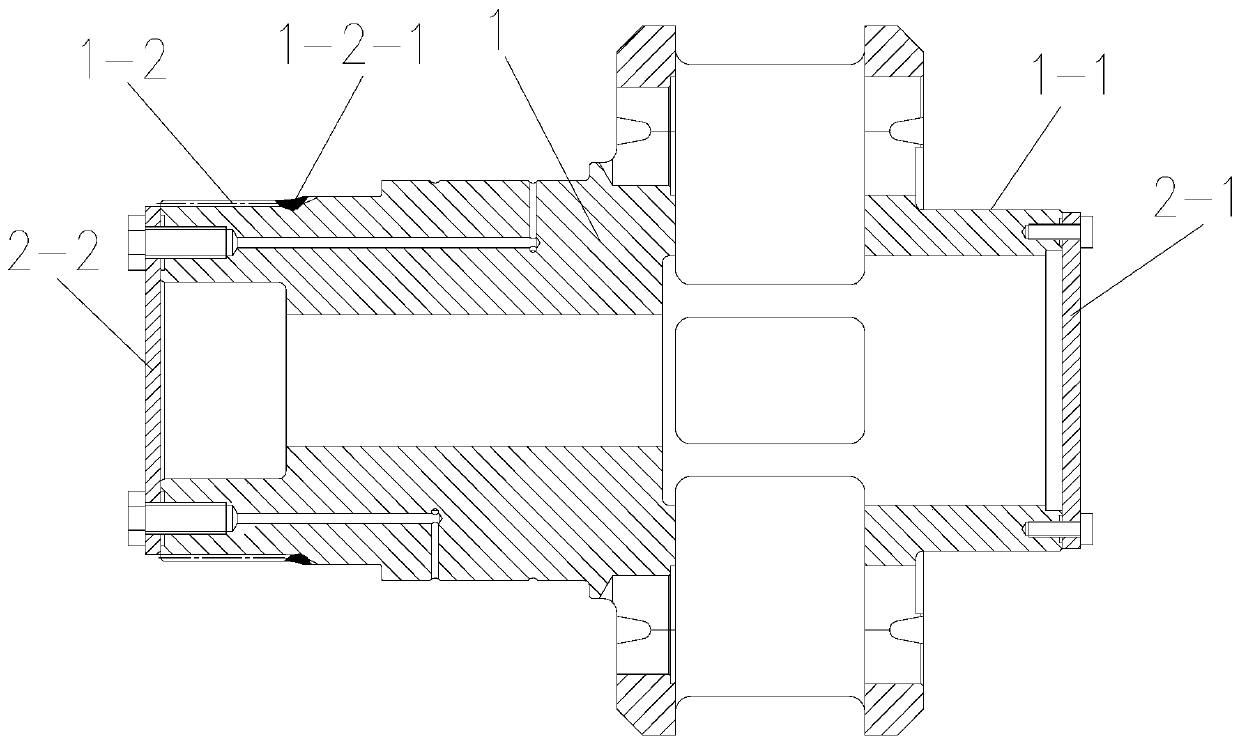

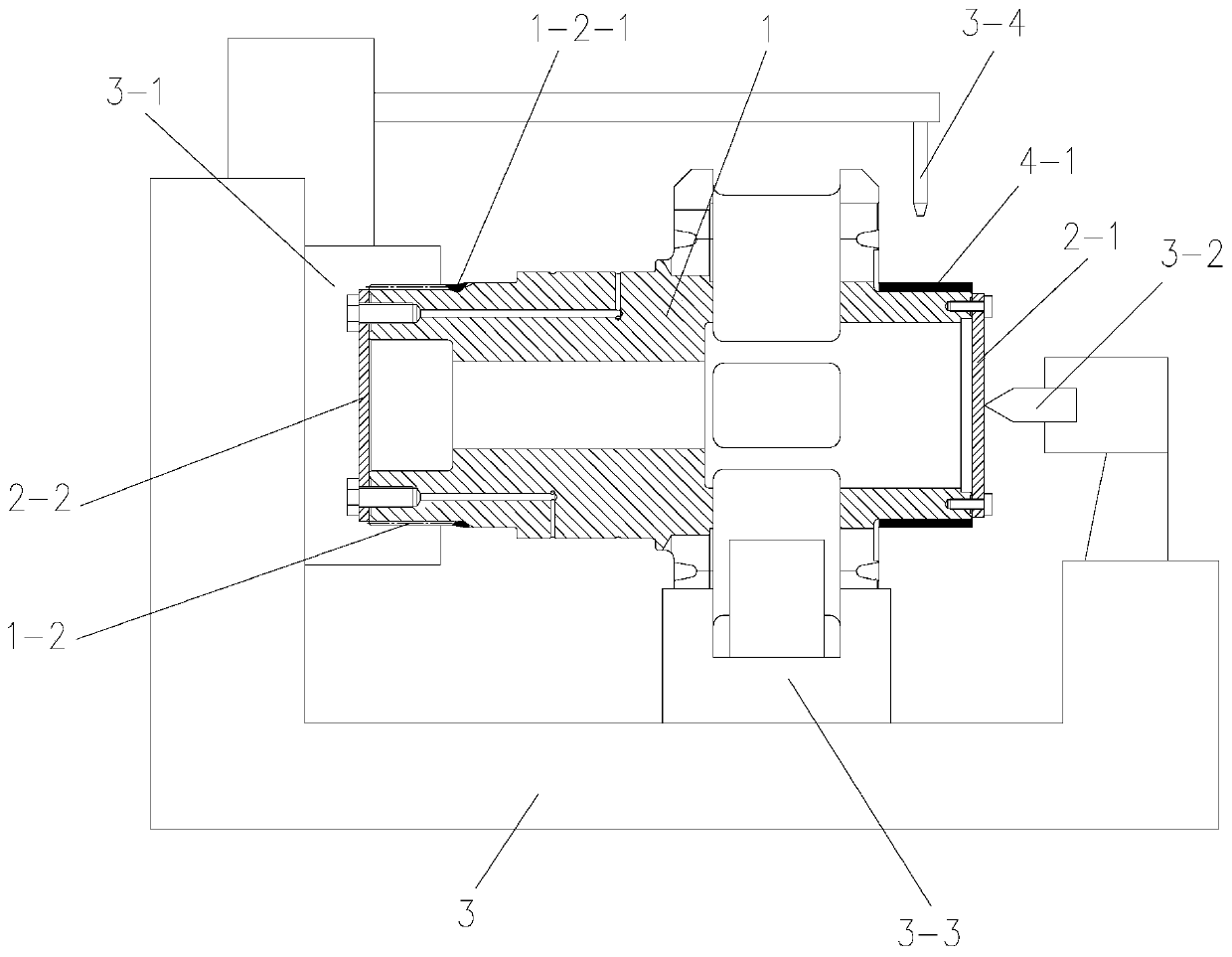

[0048] Such as Figure 1 to Figure 4 A method for repairing the planetary frame of a shearer based on laser cladding welding is shown, the method includes the following steps:

[0049] Step 1. Pre-weld treatment of laser cladding welding, specifically including the following steps:

[0050] Step 101, cleaning the inner and outer surfaces of the planet carrier;

[0051] In this embodiment, the process of cleaning the inner and outer surfaces of the planetary carrier in step 101 includes: first, cleaning the dirt on the inner and outer surfaces of the planetary carrier laser cladding head 1; secondly, cleaning the planetary carrier laser with gasoline or cleaning agent For the inner and outer surfaces of the cladding head 1, after drying the planet carrier laser cladding head 1, use a rust remover to remove the rust on the inner and outer surfaces of the planet carrier laser cladding head 1; finally, use compressed air to complete the cleaning Dry and clean the inner and outer...

Embodiment 2

[0093] The difference from Embodiment 1 is that in this embodiment, the difference between the outer diameter of the cylindrical segment connecting shaft 1-1 after the first outer circle machining and the outer diameter of the cylindrical segment connecting shaft 1-1 before wear The value is 3mm.

[0094] In this embodiment, during the process of laser cladding welding on the outer circular surface of the connecting shaft of the cylindrical section, the overlap width between two adjacent cladding layers is 0.6 mm, and the single-layer cladding layer The value range of the thickness is 0.5mm; when the outer diameter of the annular repair cladding layer 4-1 is greater than the outer diameter of the base material of the cylindrical section connecting shaft 1-1, and the annular repair cladding layer When the difference between the outer diameter of the layer 4-1 and the outer diameter of the base material of the cylindrical connecting shaft 1-1 is 1.5 mm, the laser cladding head 3...

Embodiment 3

[0105] The difference from Embodiment 1 is that in this embodiment, the difference between the outer diameter of the cylindrical segment connecting shaft 1-1 after the first outer circle machining and the outer diameter of the cylindrical segment connecting shaft 1-1 before wear The value is 4mm.

[0106] In this embodiment, in the process of laser cladding welding on the outer circular surface of the connecting shaft of the cylindrical section, the overlapping width between two adjacent cladding layers is 0.8 mm, and the single-layer cladding layer The value range of the thickness is 0.6mm; when the outer diameter of the annular repair cladding layer 4-1 is greater than the outer diameter of the base material of the cylindrical section connecting shaft 1-1, and the annular repair cladding layer When the difference between the outer diameter of the layer 4-1 and the outer diameter of the base material of the cylindrical connecting shaft 1-1 is 2mm, the laser cladding head 3-4 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| Surface roughness | aaaaa | aaaaa |

| Surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com