Reverse V-shaped granule magnesium molten iron desulfuring spray gun

A technology of hot metal desulfurization and granular magnesium, which is applied in the field of ferrous metallurgy, can solve the problems of increasing maintenance labor, reducing the service life of spray guns, and prolonging processing time, so as to simplify maintenance and repair, shorten processing cycle, and high magnesium absorption rate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

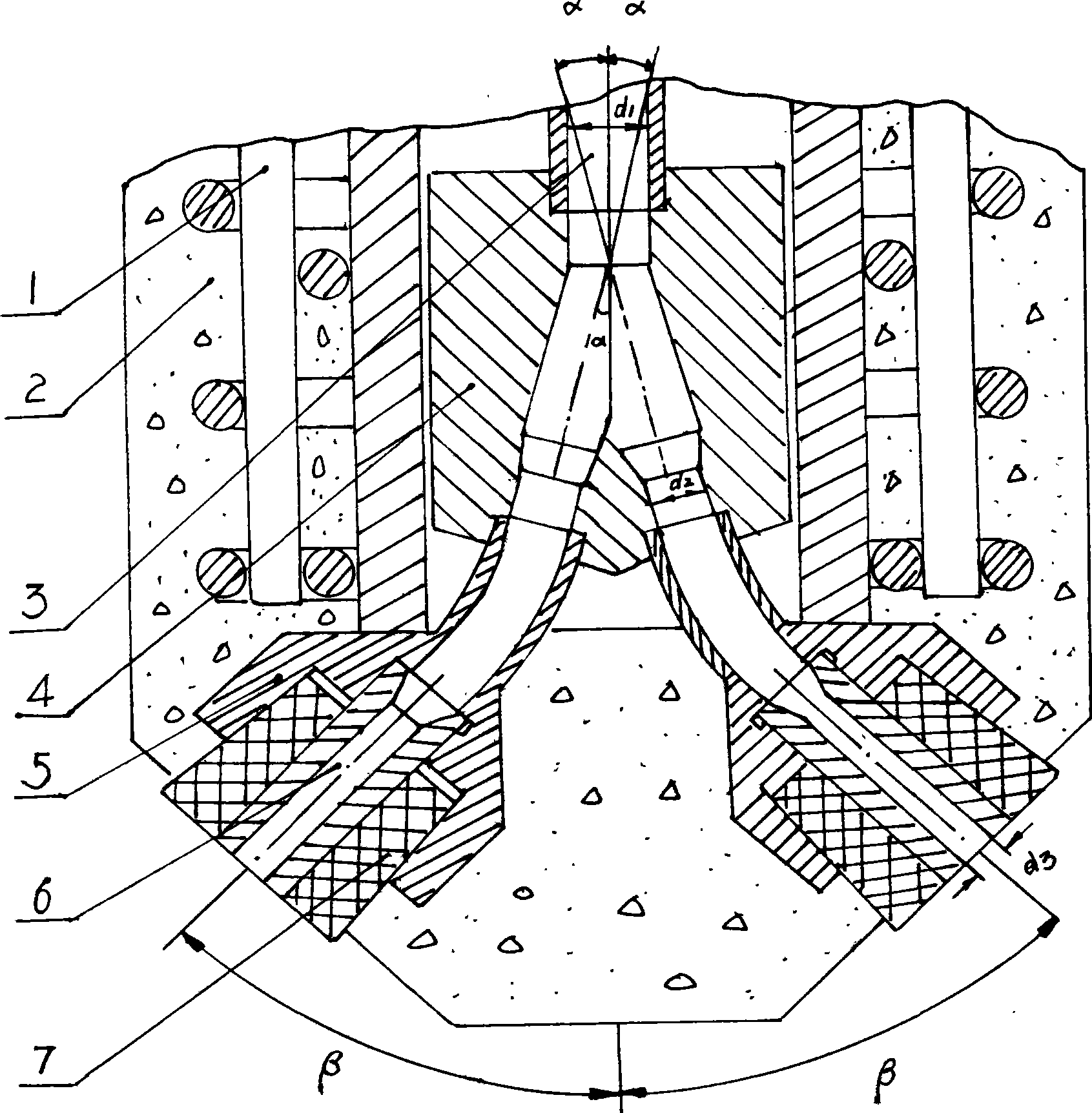

[0020] As shown in the figure, the desulfurization spray gun with inverted V-shaped granular magnesium molten iron includes the gun body; the gun body includes a skeleton 1 equipped with a refractory lining 2, a channel 3 placed in the gun body, a material flow distributor 4 and an elbow 5 ; The inlet port of the material flow distributor 4 is matched with the outlet port of the channel 3; the outlet port of the material flow distributor 4 is connected with the inlet port of the elbow 5 . The end of the elbow 5 is provided with a nozzle 6 . The outside of the nozzle 6 is provided with a refractory sleeve 7 . The outlet port of the material flow distributor 4 is detachably connected with the inlet port of the elbow 5 ; the end of the elbow 5 is detachably connected with the nozzle 6 . The distributing angle α of the two-phase jet in the material flow distributor 4 to the longitudinal axis of the gun body is ≤15°. The bending angle of the curved pipe 5 to the longitudinal axis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com