Micro LED transfer method, display panel and display device

A display panel and transfer method technology, applied in the direction of semiconductor devices, electrical components, circuits, etc., can solve the problems of complex detection and repair process, and achieve the effect of simplifying the detection and repair process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

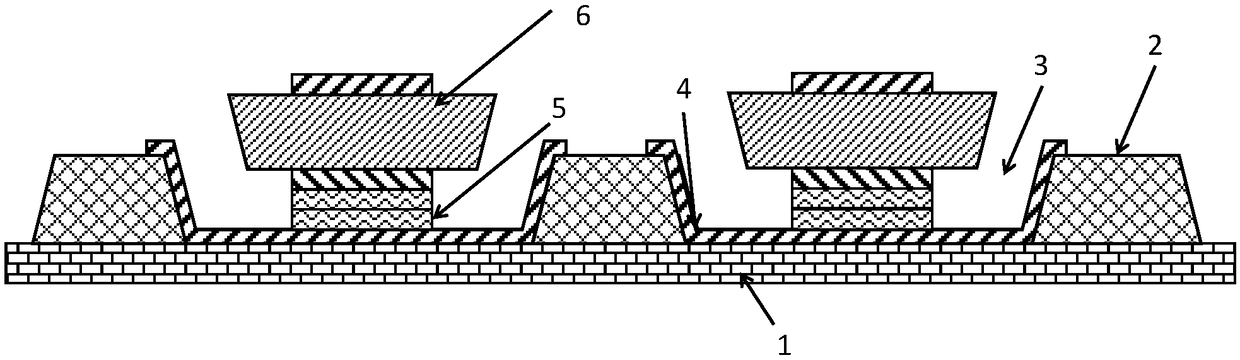

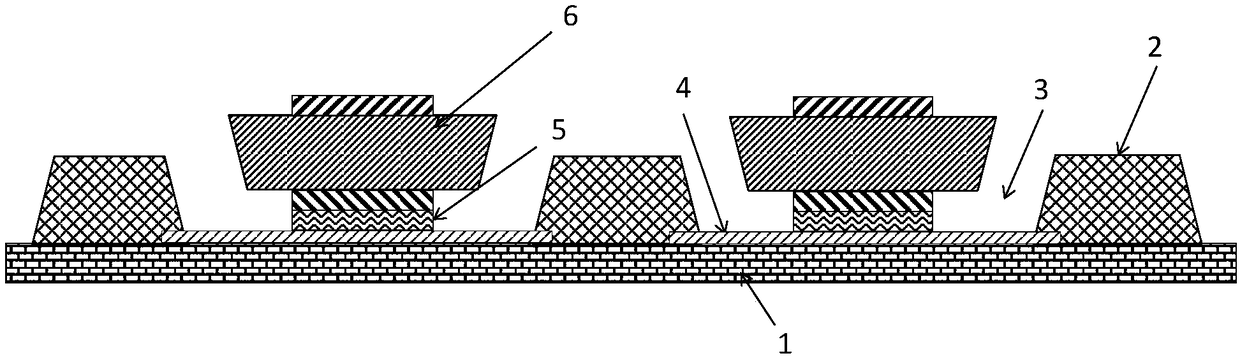

[0044] As mentioned in the background technology, the mass transfer technology of direct transfer or indirect transfer in the prior art detects the Micro LED after bonding the Micro LED on the receiving substrate, and then detects it through the detection circuit. If an abnormal Micro LED is detected, Then replace and repair the abnormal Micro LED, but this makes the subsequent detection and repair process more complicated.

[0045]The inventors found that in the prior art, the direct transfer or indirect transfer of Micro LEDs does not involve the detection of Micro LEDs, but after the transfer of all Micro LEDs is completed, a specific detection process is adopted to detect Micro LEDs. When the Micro LEDs with abnormal display appear, follow-up repair process is adopted to repair the Micro LEDs with abnormal display, for example, the Micro LEDs with redundant transfer are used to replace the Micro LEDs with abnormal Replacement, the replacement of the bonded Micro LED specif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com