Detection tool structure for beam brackets on two sides

A beam support and inspection tool technology, applied in the direction of mechanical counter/curvature measurement, etc., can solve the problems of complex process, long cycle, large error, etc., and achieve the effect of simple detection process, short cycle and high accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

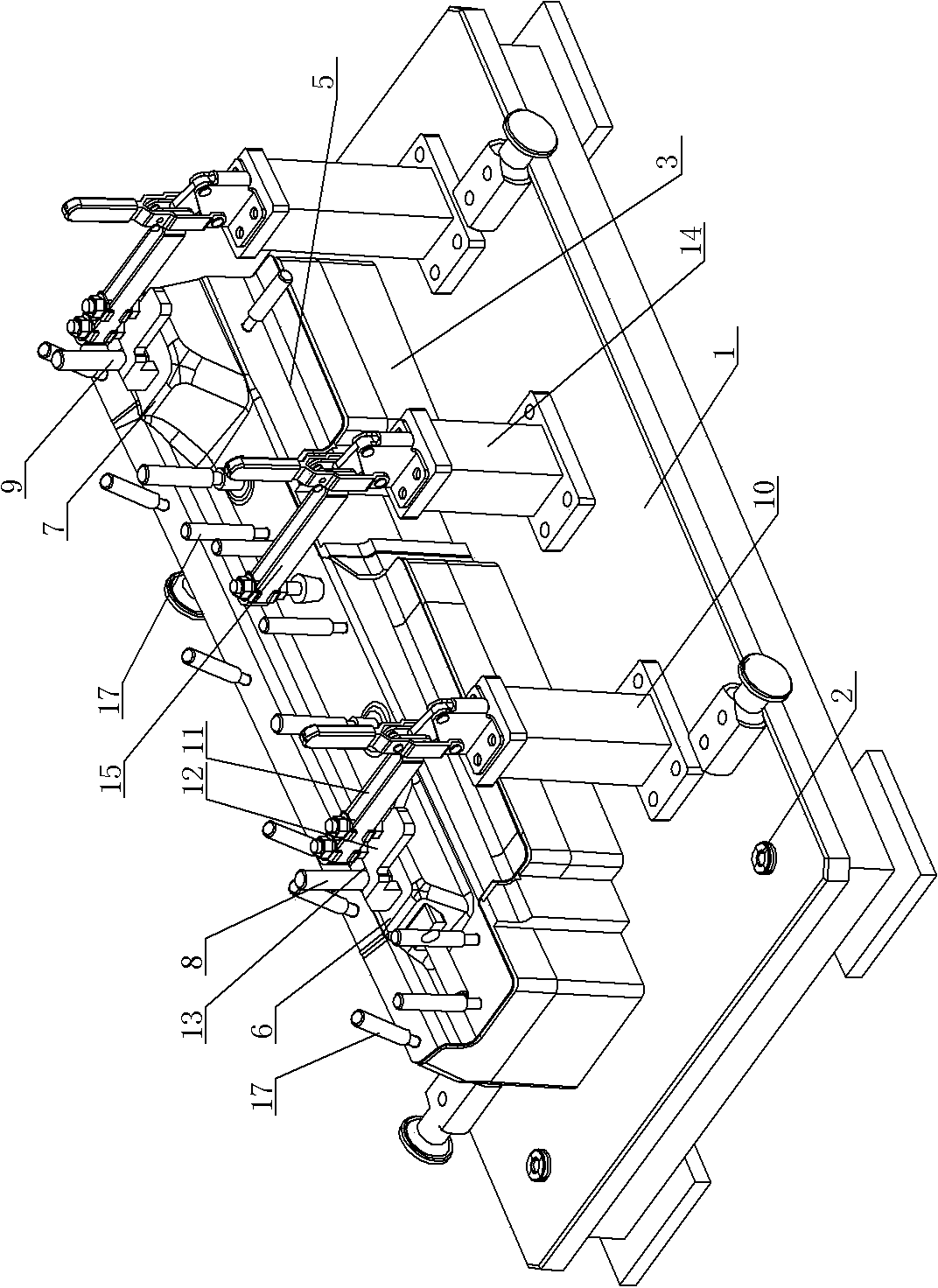

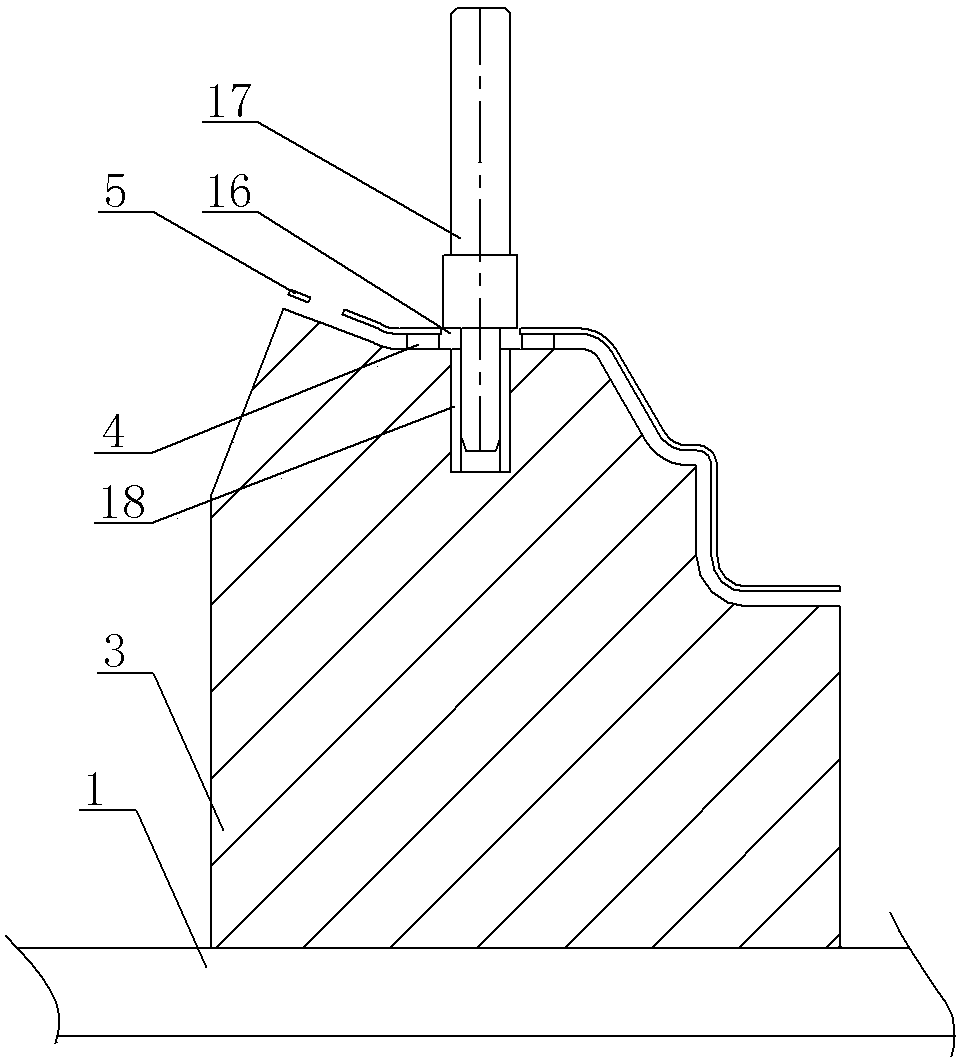

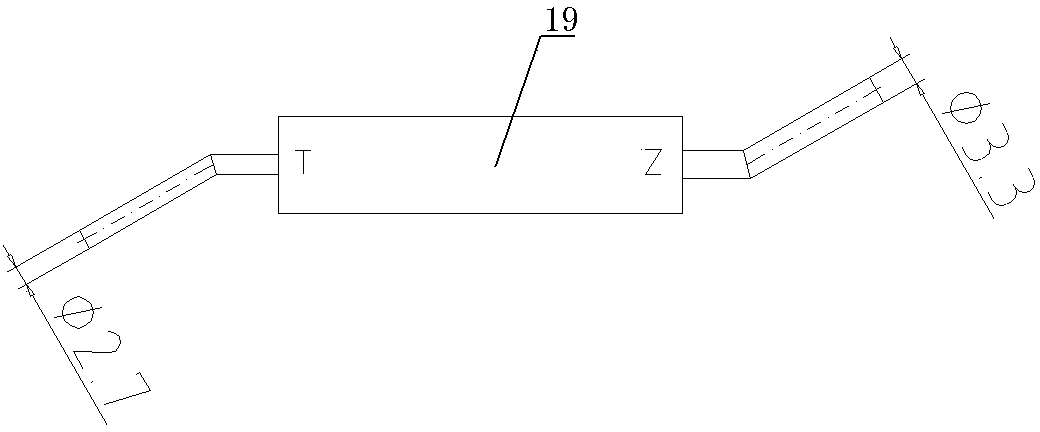

[0009] See Figure 1 ~ Figure 3 , which includes a base plate 1, where three corners of the base plate 1 are respectively provided with reference sleeves 2, and the simulation block 3 is supported on the upper surface of the base plate 1, and the upper surface of the simulation block 3 is provided with an upwardly convex positioning bump 4, and the positioning protrusion The raised height of the block 4 is 3 mm, and the lower surface of the beam bracket 5 on both sides is close to the upper end surface of the positioning bump 4 in the detection state, and the front bump 6 and the rear bump 7 of the analog block 3 are set at corresponding positions There are front-end positioning pins 8 and rear-end positioning pins 9, and a pressure clamp support 10 is arranged at one side of the front protrusion 6 and the rear protrusion 7 of the analog block 3, and the pressure clamp support 10 is connected to the pressure clamp 11 through a rotating shaft. The lower end of the clamp 11 is f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com