Inspection device structure of tower column reinforcing plate

A technology of strengthening plates and towers, applied in mechanical counters/curvature measurement and other directions, can solve the problems of complex detection process, low efficiency and long cycle, and achieve the effect of high accuracy, high efficiency and short cycle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

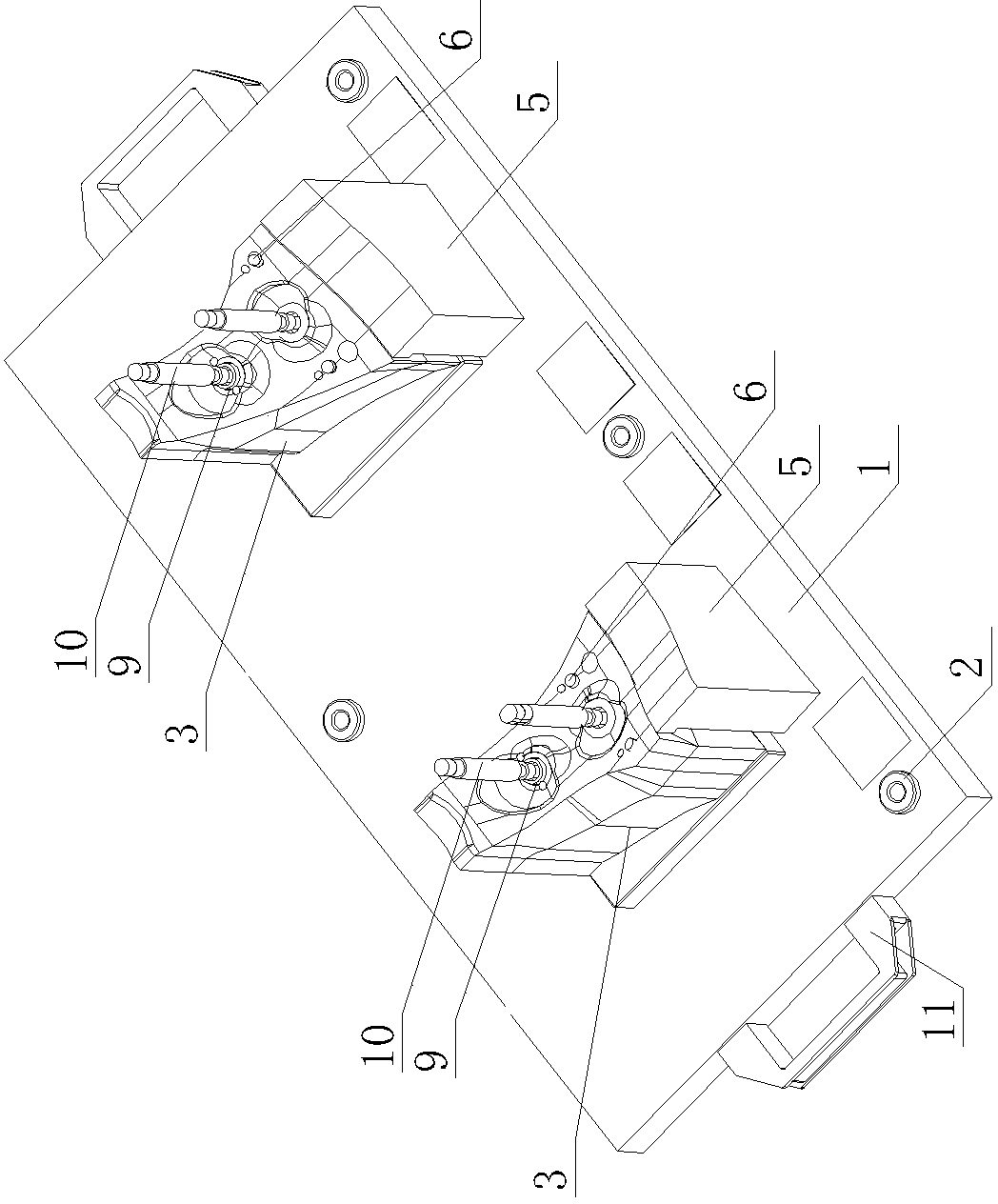

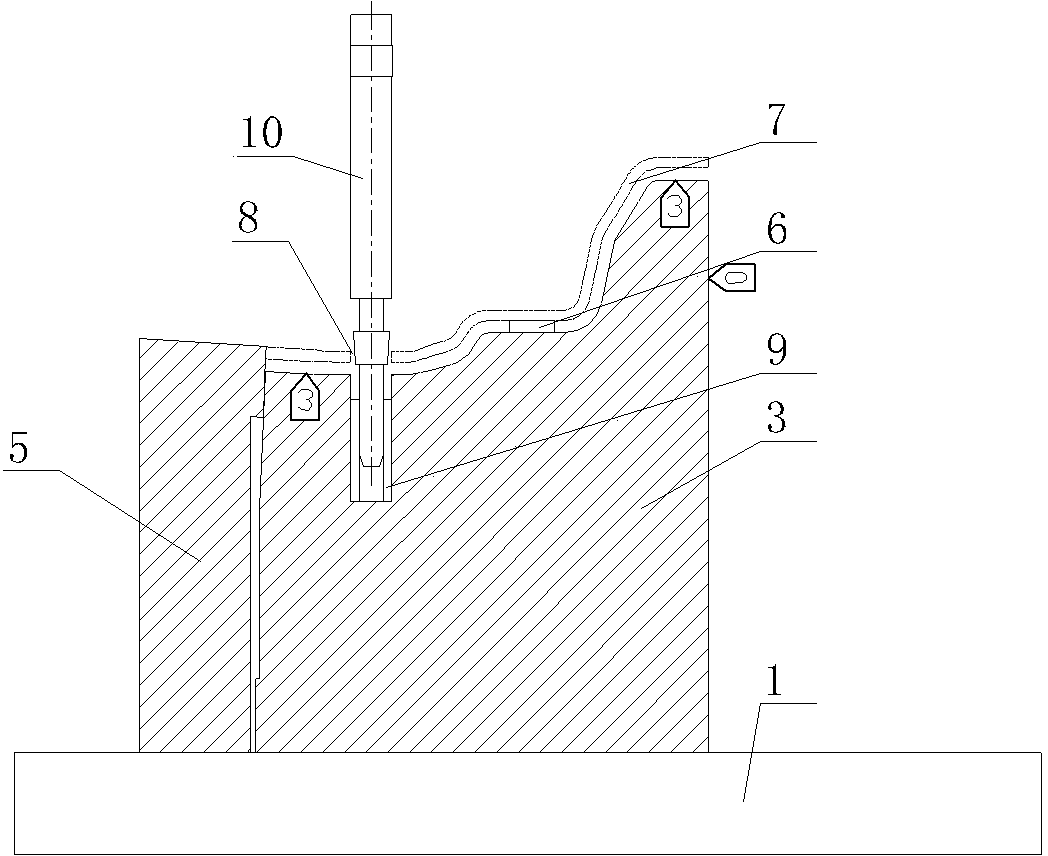

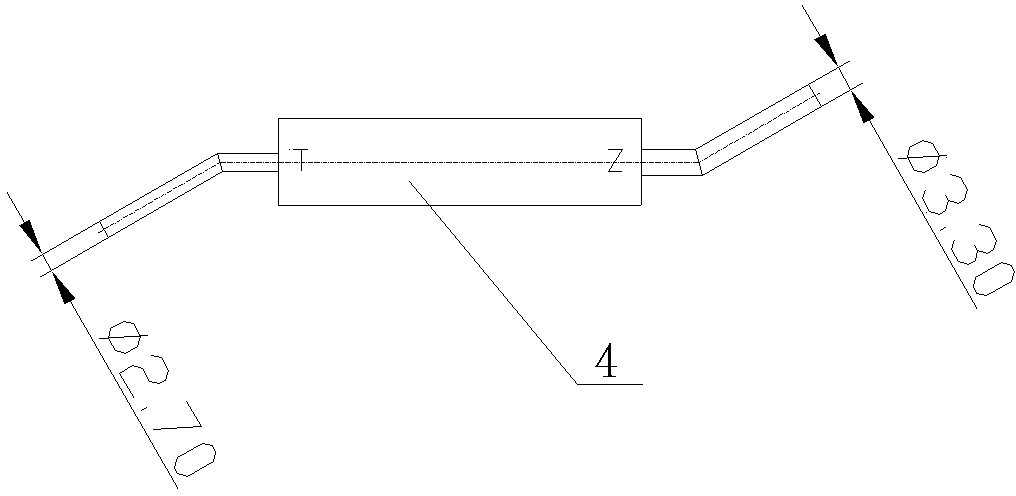

[0009] See Figure 1 ~ Figure 3 , which includes a base plate 1, a reference sleeve 2 is provided at the front, middle, and rear positions of one side of the base plate 1, and a reference sleeve 2 is provided at the middle position of the other side, and two symmetrical analog blocks 3 are respectively arranged on the base plate 1. On the end face, the front end of each analog block 3 is provided with a limit block 5, and the upper surface of the analog block 3 is arranged with a positioning bump 6, and the positioning bump 6 protrudes 3mm. On the upper end surface of the bump 6, a positioning hole 9 is provided on the analog block 3 corresponding to the slot 8 of the tower reinforcement plate 7, and the detection pin 10 is inserted into the corresponding positioning hole 9 after passing through the corresponding slot 8. One of the analog blocks 3 of the block detects the left tower column reinforcement plate, and the other detects the right tower column reinforcement plate. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com