Checking fixture structure for upper cover plate of catalytic converter

The technology of catalytic converter and cover plate is applied in the field of the inspection tool structure of the upper cover plate of the catalytic converter, which can solve the problems of complex detection process, low efficiency and long period, and achieve the effects of high accuracy, high efficiency and short period.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

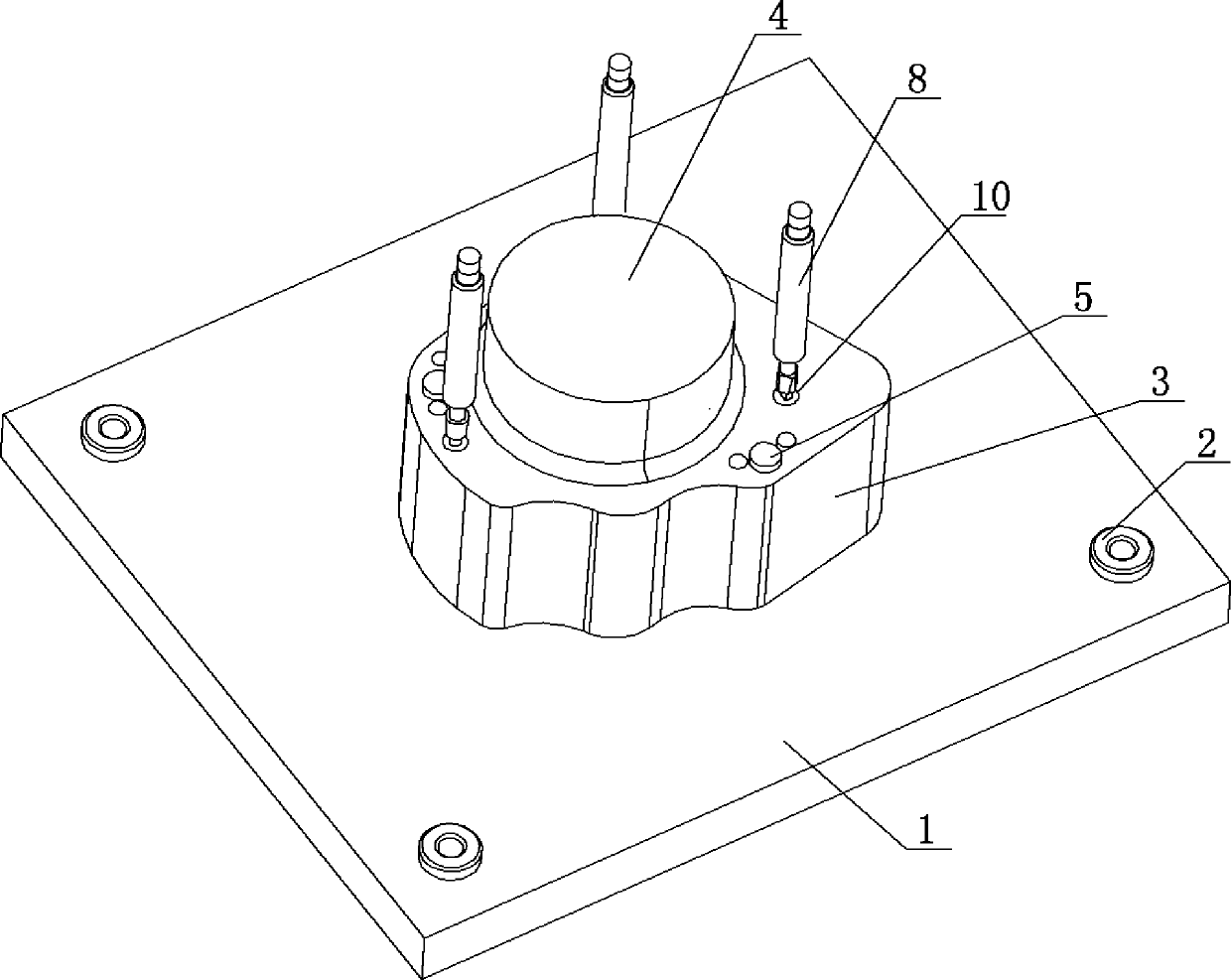

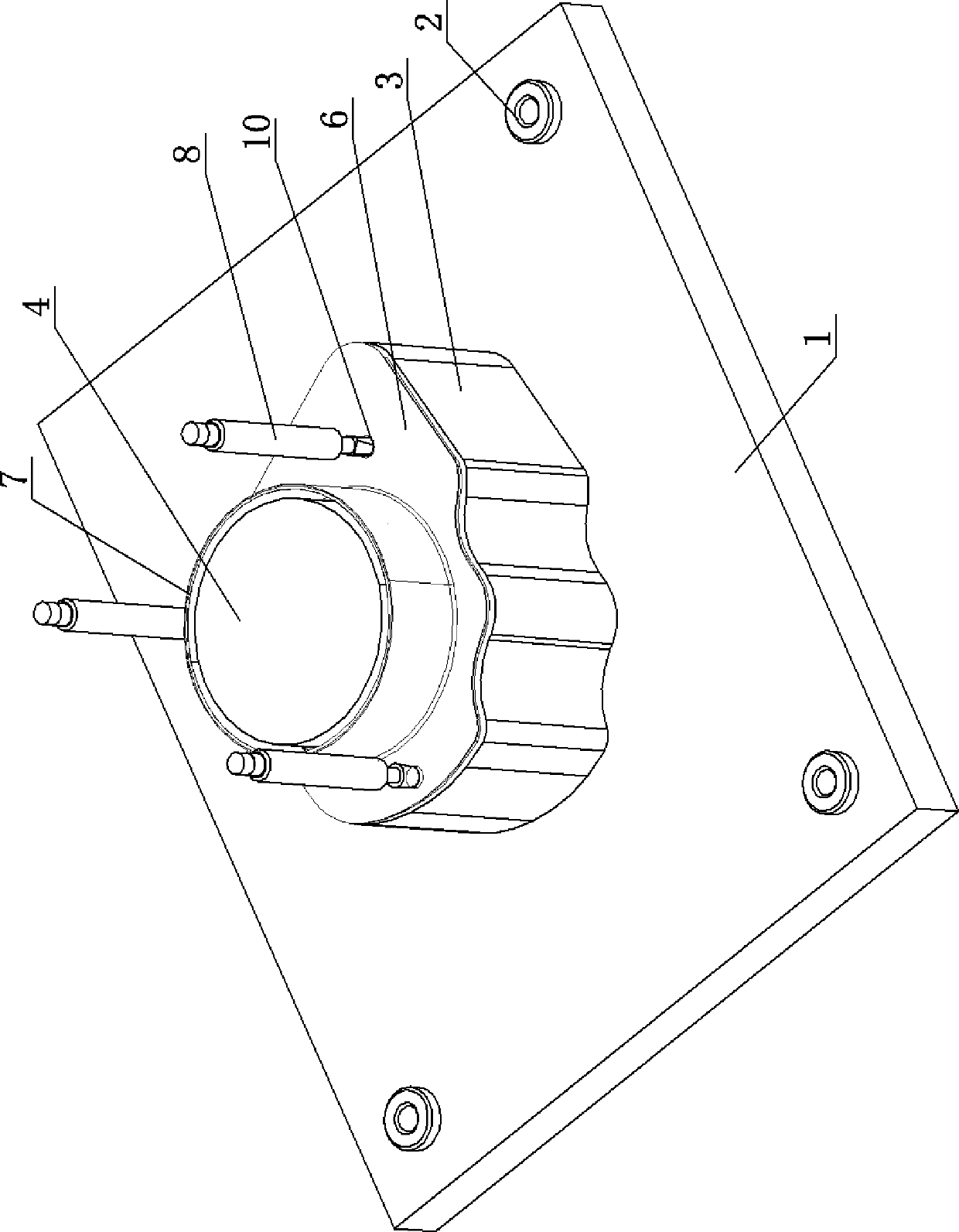

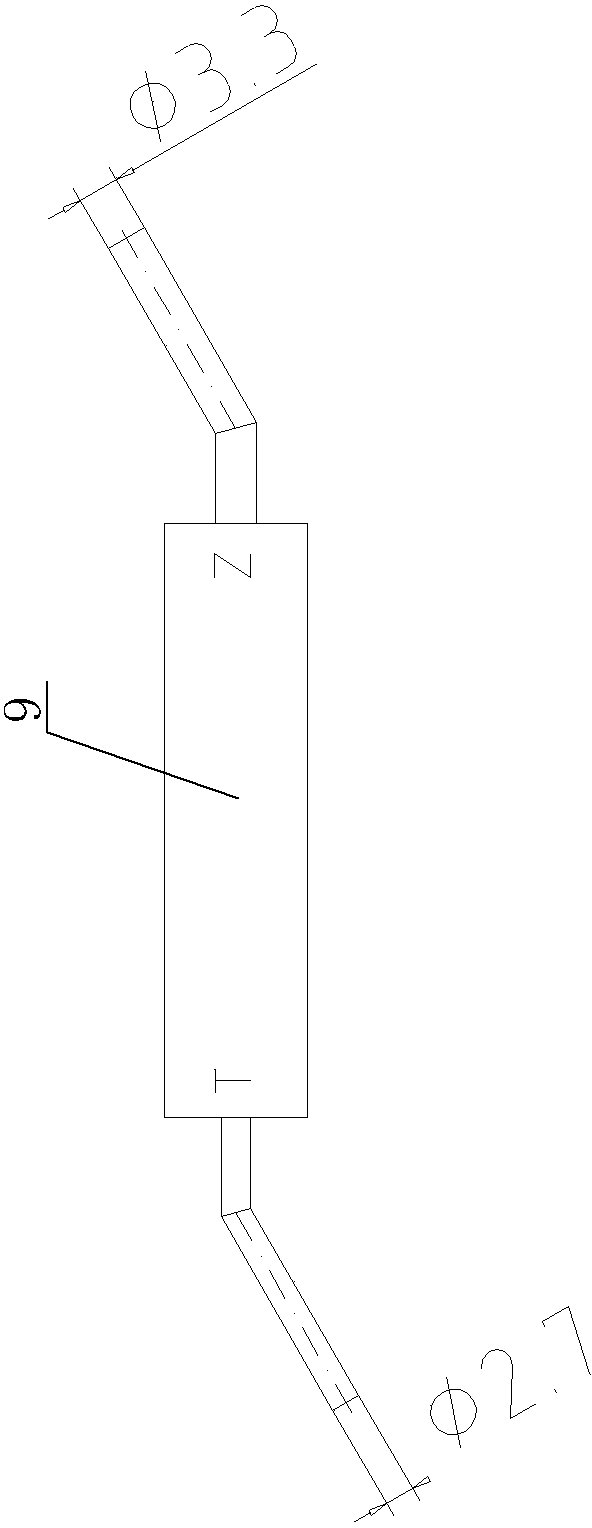

[0009] See Figure 1 ~ Figure 3 , which includes a bottom plate 1, where three corners of the bottom plate 1 are respectively provided with reference sleeves 2, the upper end surface of the bottom plate 1 is provided with a simulation block 3, the center of the simulation block 3 is an upper convex block structure 4, and the Positioning bumps 5 are arranged in the circumferential direction, and the height of the positioning bumps 5 is 3 mm. Under the detection state, the lower surface of the upper cover plate 6 of the catalytic converter is pressed against the upper end surface of the positioning bumps 5 at the corresponding position, and the raised block structure 4 Through the circular hole 7 of the upper cover plate 6 of the catalyst, the analog block 3 is provided with corresponding positioning pins 8 corresponding to the positions of the three holes 10 on the upper end surface of the upper cover plate 6 of the catalytic converter, and one of the positioning pins 8 is used ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com