Hollow displacing repairing method of hollow exterior wall tile

An empty drum and ceramic tile technology, applied in building maintenance, construction, building construction, etc., can solve the problems of complex repair process and large amount of engineering, and achieve the effect of simple repair process, short construction period and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] A hollowing replacement and repair method for hollowing exterior wall tiles, comprising the following steps:

[0032] (1) Empty drum inspection steps

[0033] In this step, use a hollow hammer to determine the range of the hollow drum and use a marker to draw the range of the outer wall that should be cut and removed;

[0034] (2) Steps of cutting and eradicating hollow tiles

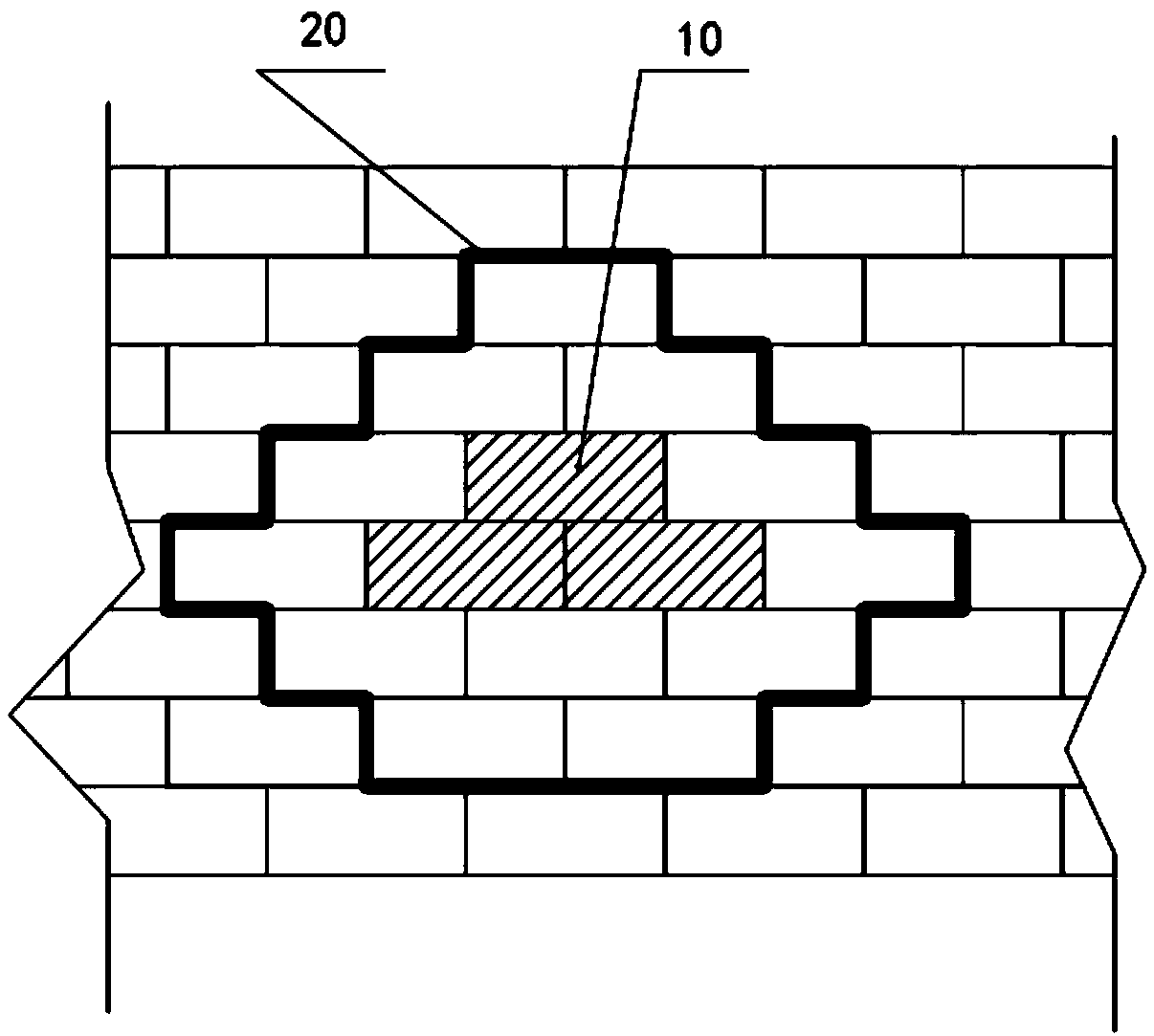

[0035] In this step, first use a cutting machine to cut the edges of the exterior wall tiles in the range of the exterior wall surface determined in step (1) that should be cut and removed, and then use tools to chisel and shovel the exterior wall surface until it is completely removed; see figure 1 , The hollow part 10 is removed to the structural layer, and the outward expansion part 20 is removed to the surface of the crack-resistant layer. The outward extension part 20 is not less than 10 tiles of the hollow part in the vertical direction, and not less than 10 tiles of the hollow part in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com