Repair method for ceramic matrix composite material

A composite material and repair method technology, which is applied in the field of ceramic matrix composite material repair, and achieves the effects of simple repair process, short cycle, and improved high-temperature oxidation resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

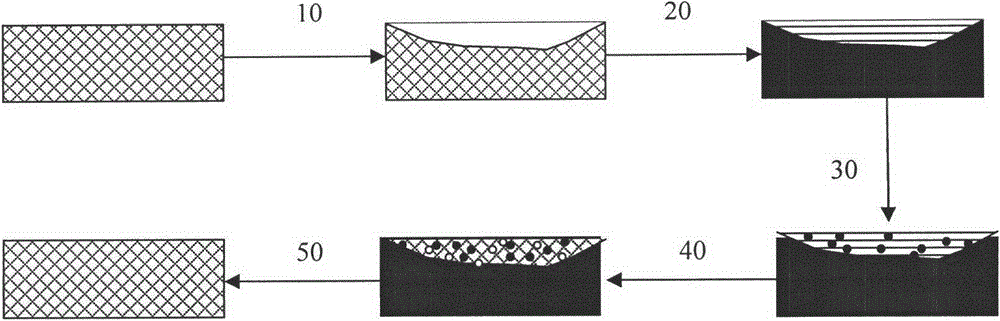

Method used

Image

Examples

Embodiment 1

[0020] (1) Ultrasonic cleaning of the worn ceramic matrix composite material sample, the cleaning time is 20 minutes;

[0021] (2) Composite material after drying;

[0022] (3) Use carbon fiber prepreg cloth to fill the defective parts, mold and solidify at a pressure of 30MPa;

[0023] (4) The temperature is 100°C, and the curing time is 3 hours;

[0024] (5) Put the above solidified sample into the reaction furnace, slowly rise to high temperature pyrolysis under vacuum atmosphere, the pyrolysis temperature is 1100°C, and the pyrolysis time is 2h;

[0025] (6) After the prepreg is decomposed, it is coated with boron carbide and silicon nitride nanopowder slurry, and enters the large gap between the fiber bundles;

[0026] (7) In a vacuum atmosphere, the temperature is raised to the reaction temperature, trichloromethylsilane gas is introduced, hydrogen is used as a carrier gas, and argon is used as a diluent gas to infiltrate silicon carbide with chemical vapor phase, and ...

Embodiment 2

[0028] (1) Ultrasonic cleaning of the worn ceramic matrix composite material sample, the cleaning time is 30 minutes;

[0029] (2) After drying, the unrepaired part of the composite material is pasted with graphite paper;

[0030] (3) Use carbon fiber prepreg cloth to fill the defective parts, mold press and cure, and the pressure is 50MPa;

[0031] (4) The temperature is 120°C, and the curing time is 4 hours;

[0032] (5) Put the above solidified sample into the reaction furnace, slowly rise to high temperature pyrolysis under vacuum atmosphere, the pyrolysis temperature is 1000°C, and the pyrolysis time is 4h;

[0033] (6) After the prepreg is decomposed, it is coated with boron carbide and silicon nitride nanopowder slurry, and enters the large gap between the fiber bundles;

[0034] (7) In a vacuum atmosphere, the temperature is raised to the reaction temperature, trichloromethylsilane gas is introduced, hydrogen is used as a carrier gas, and argon is used as a diluent g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com