Preparation method of photoresponseive cellulose nanocrystalline/fluorine-containing polyacrylate self-repairing material

A technology of polyacrylate and self-healing material is applied in the field of preparation of light-responsive cellulose nanocrystal/fluorine-containing polyacrylate self-healing material to achieve the effects of improving performance, wide source of raw materials and high optical activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

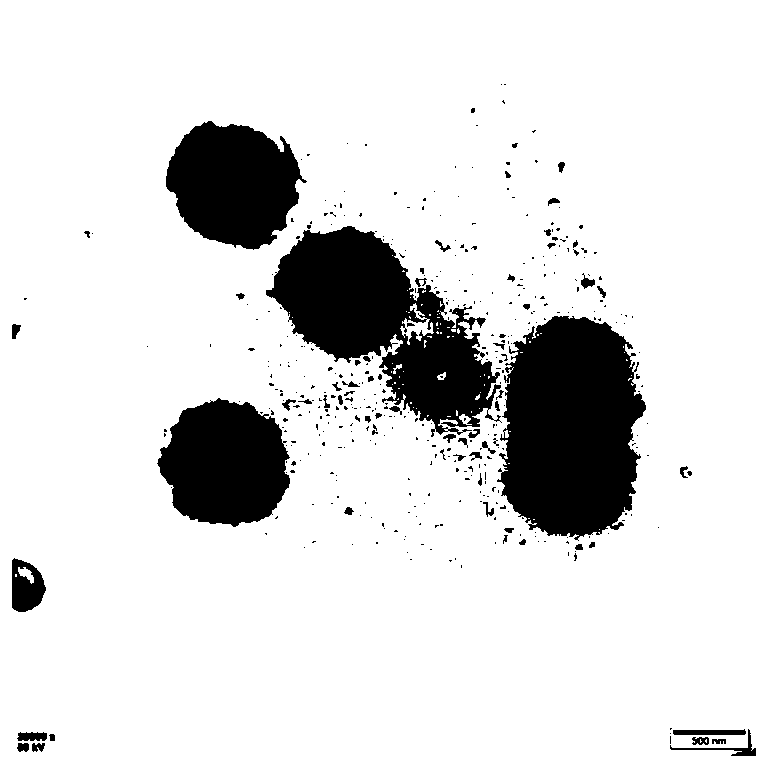

Image

Examples

Embodiment 1

[0042] Step 1. Mix the modified cellulose nanocrystals, water, and mixed monomers with a mass ratio of 0.01:20:1, and emulsify with an ultrasonic cell pulverizer for 25 minutes to obtain a stable milky white Pickering emulsion.

[0043] Step 2.1, Transfer the Pickering emulsion to a three-necked flask equipped with a stirrer, a reflux condenser, and an argon inlet tube;

[0044] Step 2.2. Place the three-necked flask in a water bath, and at a stirring speed of 100r / min, pass argon gas into the three-necked flask through the argon gas inlet tube for 20 minutes; after heating to 70°C, dropwise add a concentration of 1.5wt within 30 minutes % azobisisobutylamidine hydrochloride initiator aqueous solution, after the dropwise addition is completed, keep warm for 2 hours, and the reaction ends;

[0045] Step 2.3, cooling the reactants in the three-necked flask to room temperature; the filtrate obtained by filtering is a photoresponsive cellulose nanocrystal / fluorine-containing polya...

Embodiment 2

[0049] Step 1. Mix the modified cellulose nanocrystals, water and mixed monomers with a mass ratio of 0.02:25:1, and emulsify with an ultrasonic cell pulverizer for 30 minutes to obtain a stable milky white Pickering emulsion.

[0050] Step 2.1, Transfer the Pickering emulsion to a three-necked flask equipped with a stirrer, a reflux condenser, and an argon inlet tube;

[0051] Step 2.2. Place the three-necked flask in a water bath, and at a stirring speed of 150r / min, pass argon gas into the three-necked flask through the argon gas inlet tube for 25 minutes; after heating up to 75°C, add dropwise a concentration of 3wt% within 60 minutes Azobisisobutylamidine hydrochloride initiator aqueous solution, after the dropwise addition is completed, the insulation reaction is carried out for 3h, and the reaction ends;

[0052] Step 2.3, cooling the reactants in the three-necked flask to room temperature; the filtrate obtained by filtering is a photoresponsive cellulose nanocrystal / fl...

Embodiment 3

[0056] Step 1. Mix the modified cellulose nanocrystals, water and mixed monomers with a mass ratio of 0.03:30:1, and emulsify with an ultrasonic cell pulverizer for 30 minutes to obtain a stable milky white Pickering emulsion.

[0057] Step 2.1, Transfer the Pickering emulsion to a three-necked flask equipped with a stirrer, a reflux condenser, and an argon inlet tube;

[0058] Step 2.2. Place the three-necked flask in a water bath, and at a stirring speed of 200r / min, pass argon gas into the three-necked flask through the argon gas inlet tube for 30 minutes; after heating up to 80°C, add a concentration of 6wt% within 90 minutes. Azobisisobutylamidine hydrochloride initiator aqueous solution, after the dropwise addition is completed, the insulation reaction is carried out for 4h, and the reaction ends;

[0059] Step 2.3, cooling the reactants in the three-necked flask to room temperature; the filtrate obtained by filtering is a photoresponsive cellulose nanocrystal / fluorine-c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com