Marine water-jet propulsion passage aluminum double curved plate one-time pressure-molding technique method

A technology of water jet propulsion and compression molding, which is applied in the direction of manufacturing tools, forging/pressing/hammering machinery, metal processing equipment, etc., and can solve the problems of pressing marine aluminum hyperbolic panels, dredging and forming large curvature changes, and reverse deformation of castings Complexity and other problems, to achieve the effect of simplifying operation, ensuring molding quality and remarkable economic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

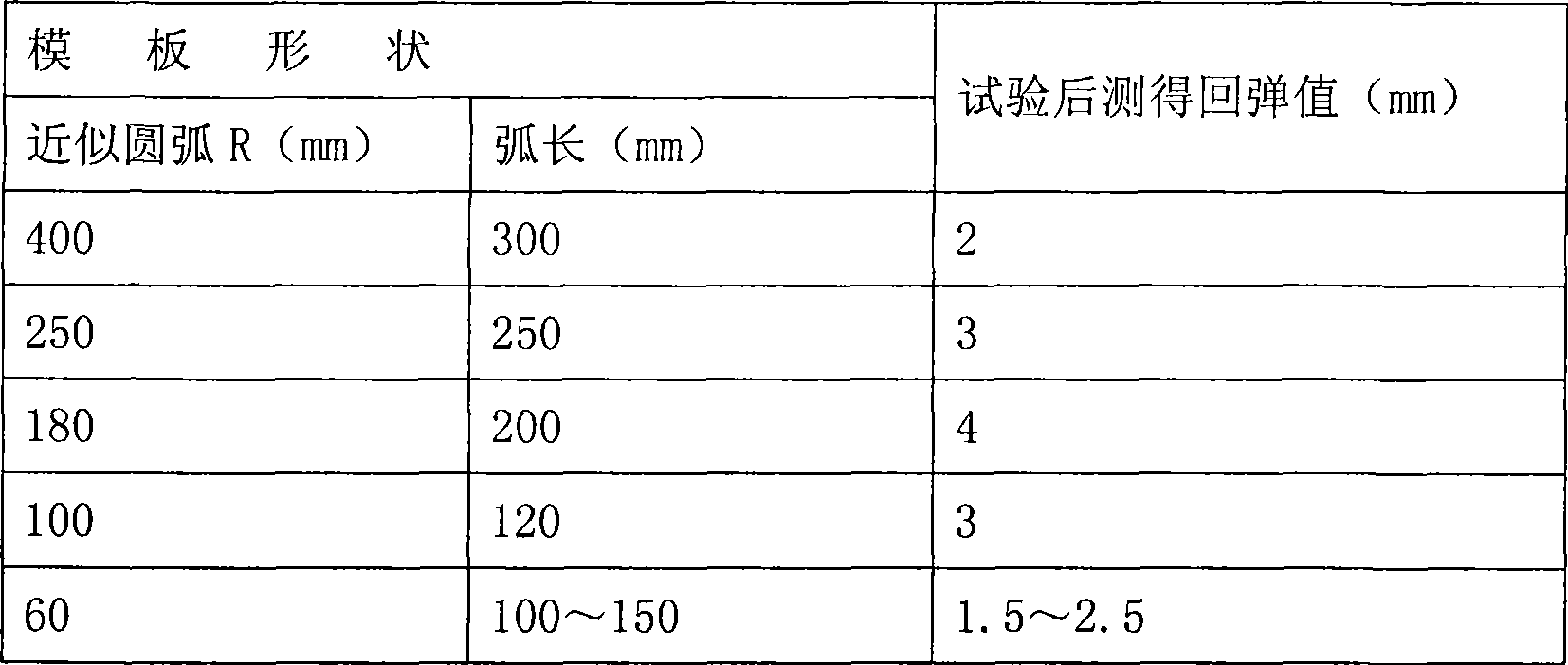

[0018] The present invention realizes one-time molding of aluminum hyperbolic panels by means of mold pressing. Firstly, linear smoothing, modeling and lofting are carried out on the hull channel structure matched with aluminum hyperbolic panel workpieces. According to the different shapes of the formwork, the upper and lower test dies (length 200mm) of various specifications are prepared with steel plates, and a test sample consistent with the structure of the hull flow channel is manufactured. Box, the special inspection sample box is made according to the smooth type value of lofting. Use the same aluminum plate (grade 5083H116, thickness 12mm) as the runner hyperbolic panel parts to carry out repeated compression tests to obtain accurate springback values (see the table below). During the experimental research on the amount of rebound, the principles of easing curvature, gradual transition, and no abrupt change are followed.

[0019]

[0020] Determine the accurate r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com