Preparation method for high-wear-resistance and repairable conical double cylinders

A high wear-resistant, barrel technology, applied in the field of extruder components, can solve the problems of insufficient wear resistance of the bushing, uneven distribution of alloys, insufficient bonding strength, etc., to save replacement costs, improve production efficiency, High bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A preparation method of a highly wear-resistant and repairable conical double barrel, which is made by the following method:

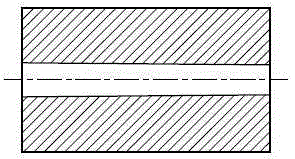

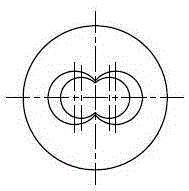

[0035] (1) Boring the 45 steel forgings, processing it into a conical double-barrel blank 1 with two intersecting inner holes and a figure-eight cross-section, such as figure 1 and figure 2 shown;

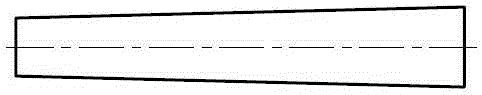

[0036] (2) Use ordinary steel to process the mandrel 2 with the same taper as the inner hole of the barrel, such as image 3 and Figure 4 As shown, the size of the mandrel is 1 mm longer than the inner hole of the barrel, and a layer of iron-based self-fluxing alloy wear-resistant layer 3 is spray-welded on the surface of the two mandrels 2. After the surface is ground, the distance from the size of the head The outer diameter at 1mm is the same as the inner hole size of the end face of the barrel, and then cut off the excess material of the two mandrels according to the inner hole size of the tapered double barrel, such as Figure 5 and Imag...

Embodiment 2

[0045] A preparation method of a highly wear-resistant and repairable conical double barrel, which is made by the following method:

[0046] (1) Boring the 40Cr forgings and processing them into conical double-barrel blanks with inner holes intersecting two circles and cross-sections in a figure-eight ring;

[0047] (2) Use ordinary steel to process a mandrel with the same taper as the inner hole of the barrel. The size of the mandrel is 2mm longer than the inner hole of the barrel. Wear-resistant layer, after grinding the surface, the size of the outer diameter at 2mm from the big and small heads is the same as the inner hole size of the end face of the barrel, and then cut off the excess material of the two mandrels according to the inner hole size of the tapered double barrel, and the cone The double-shaped barrel mandrel is inserted into the barrel blank hole and pressed tightly to form a barrel assembly;

[0048] (3) Put the barrel assembly in a vacuum furnace and heat i...

Embodiment 3

[0056] A preparation method of a highly wear-resistant and repairable conical double barrel, which is made by the following method:

[0057] (1) The 42CrMo forging is bored and processed into a conical double-barrel blank with two intersecting inner holes and a figure-eight cross-section;

[0058] (2) Use ordinary steel to process mandrels with the same taper as the inner hole of the barrel. The size of the mandrels is 3mm longer than the inner hole of the barrel, and a layer of cobalt-based self-fluxing alloy is spray-welded on the surface of the two mandrels. Wear-resistant layer, after grinding the surface, the outer diameter at 3mm from the big and small heads is the same as the inner hole size of the end face of the barrel, and then cut off the excess material of the two mandrels according to the inner hole size of the tapered double barrel, and the cone The double-shaped barrel mandrel is inserted into the barrel blank hole and pressed tightly to form a barrel assembly; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com