Full-repairing technology for housing of desulphurization circulating pump

A circulating pump and pump casing technology, which is applied in the full repair process of desulfurization circulating pump pump casings, can solve problems such as equipment outage, affecting desulfurization efficiency, and increased gap between pump port rings, etc., to achieve improved adhesion and repair process Simple, well-controlled effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] The whole repair process of the pump casing of the desulfurization circulating pump of the present invention comprises the following steps:

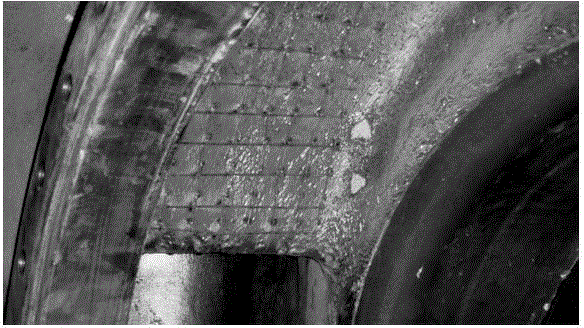

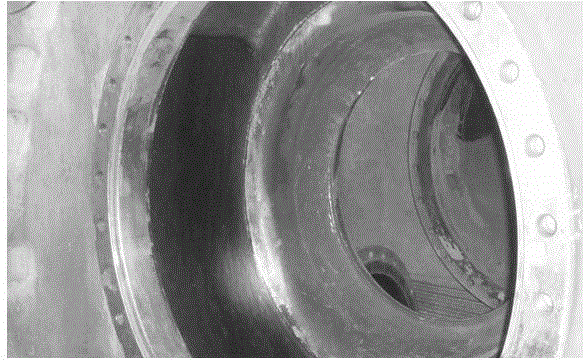

[0026] (1) According to the degree of wear and corrosion of the pump casing of the circulating pump, combined with the drawing size of the pump, the welded skeleton treatment is performed on the worn and corroded pump casing;

[0027] (2) Sand blast the flow surface of the pump body and the welded skeleton to completely remove the rust and impurities on the flow surface and corrosion pits, and control the roughness after sandblasting to about 10 μm;

[0028] (3) Isolate the whole pump, and carry out chemical cleaning at room temperature under windproof and dustproof conditions;

[0029] (4) On-site preparation of anti-wear and anti-corrosion materials: mix the Loctite small particle protective agent and the supporting curing agent at a mass ratio of 3:1, and use the cast-pile stirring method to continue stirring for 12 minutes unt...

Embodiment 2

[0033] The whole repair process of the pump casing of the desulfurization circulating pump of the present invention comprises the following steps:

[0034] (1) According to the degree of wear and corrosion of the pump casing of the circulating pump, combined with the drawing size of the pump, the welded skeleton treatment is performed on the worn and corroded pump casing;

[0035] (2) Sand blast the flow surface of the pump body and the welded skeleton to completely remove the rust and impurities on the flow surface and corrosion pits, and control the roughness after sandblasting to about 30 μm;

[0036] (3) Isolate the whole pump, and carry out chemical cleaning at room temperature under windproof and dustproof conditions;

[0037] (4) On-site preparation of anti-wear and anti-corrosion materials: mix the Loctite small particle protective agent and the supporting curing agent at a mass ratio of 3:1, and use the cast-pile stirring method to continue stirring for 15 minutes unt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com