Testing method for testing compression-shear performance of jointed rock

A test method and technology of jointed rock mass, applied in the direction of testing material strength by applying stable shear force, testing material strength by applying stable tension/pressure, etc., can solve shear failure, deviation of rock mechanical parameters, test Inaccurate measurement data and other problems, to achieve the effect of easy guarantee of accuracy, uniform force, and reduction of test errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0047] In order to further introduce the test method in detail, a specific test device is used to describe the test method. It is worth mentioning that this embodiment is only a specific example of the application of this method. Since there are many specific forms of loading devices, any oblique load applied by an oblique shear loading device is different from the normal direction applied by a normal loading device. The method of intersecting the loads in the predetermined shear plane of the tested piece, thereby avoiding the bending moment during the loading process, and using a corresponding control system to control the loading device is within the protection scope of the present application.

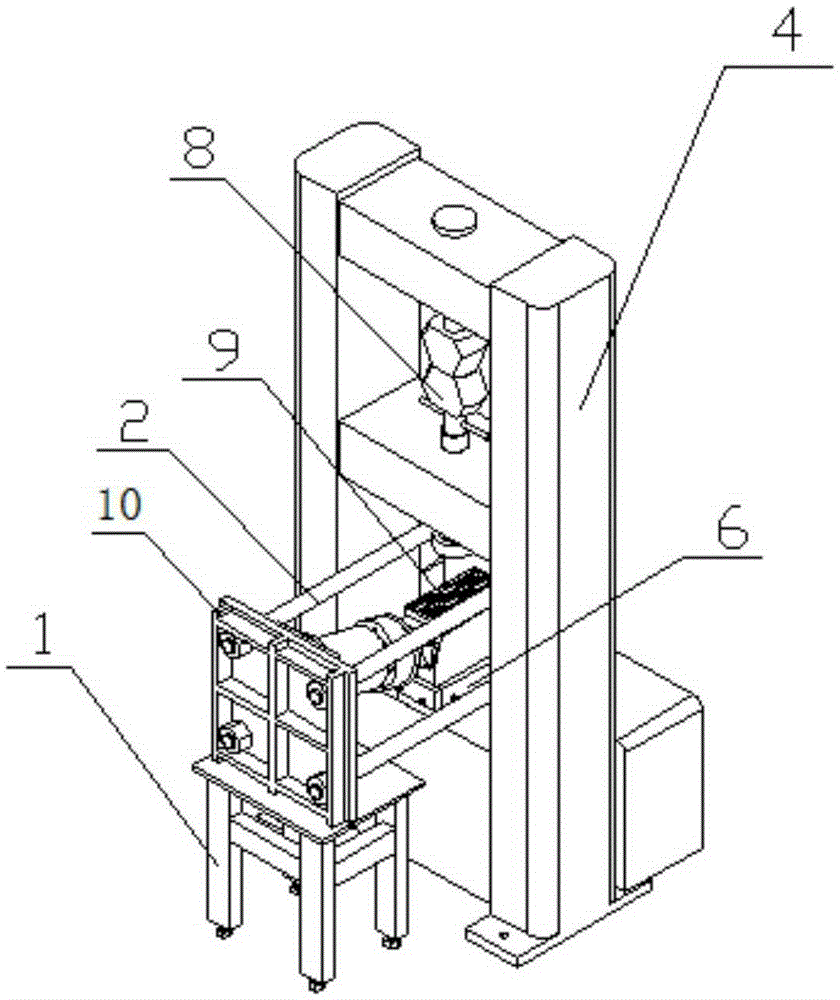

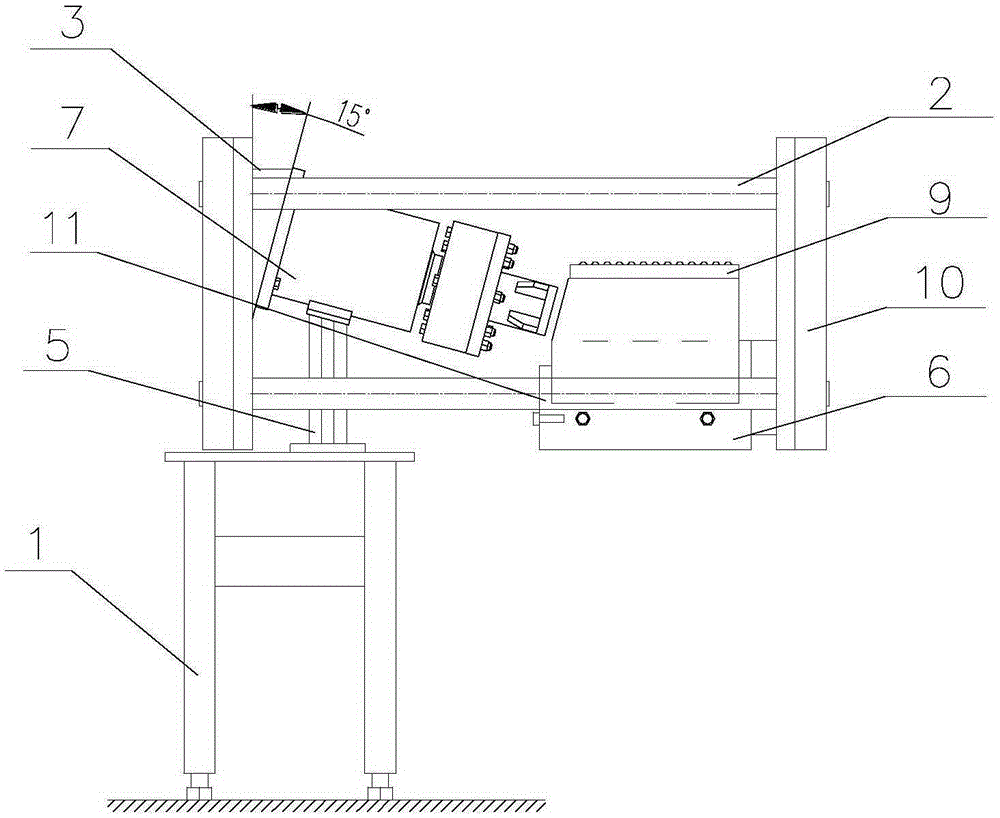

[0048] The device is a multifunctional fractured rock mass compression-shear test device, such as figure 1 , figure 2 Shown:

[0049] Including the main ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com