Compression-resisting clamping tool for testing compression resistance of non-metallic materials

A non-metallic material and anti-compression technology, which is applied in the direction of analyzing materials, measuring devices, strength characteristics, etc., can solve the problems of unretrieved literature related to anti-compression fixtures, etc., and achieve the effect of high hardness and accurate positioning of the pressure-bearing surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] For example, to test the compressive strength of a concrete sample.

[0034] First, the MTS testing machine is used to respectively pull the clamping device for clamping the upper part and the lower part of the clamp according to the present invention to an appropriate distance. After the compression clamp according to the present invention is installed at this distance, the remaining space can be Place the sample to be tested with a margin of 2-8mm;

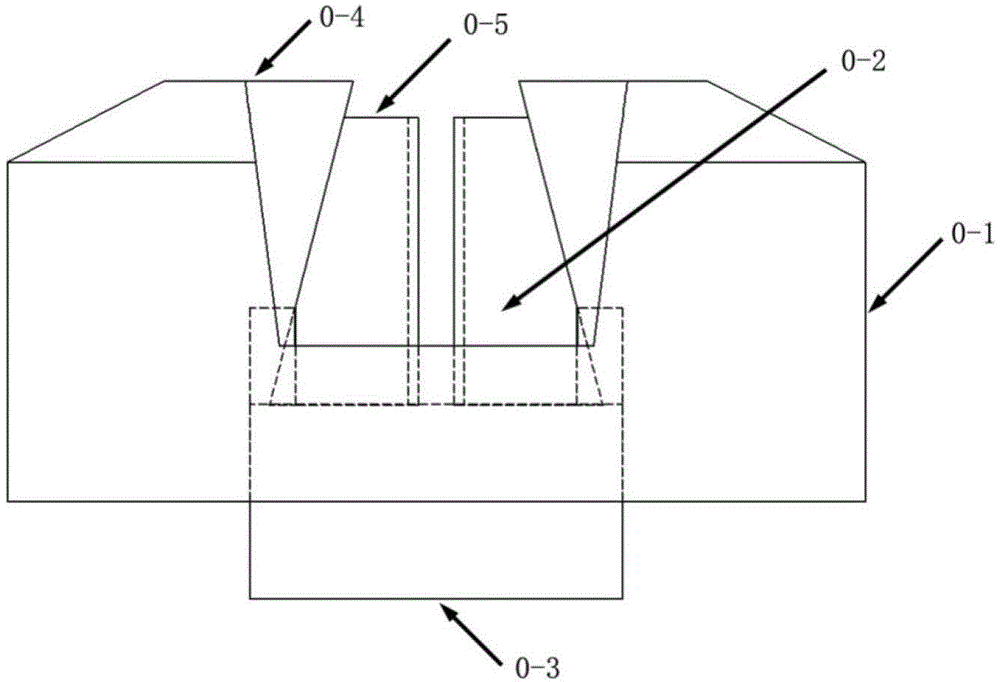

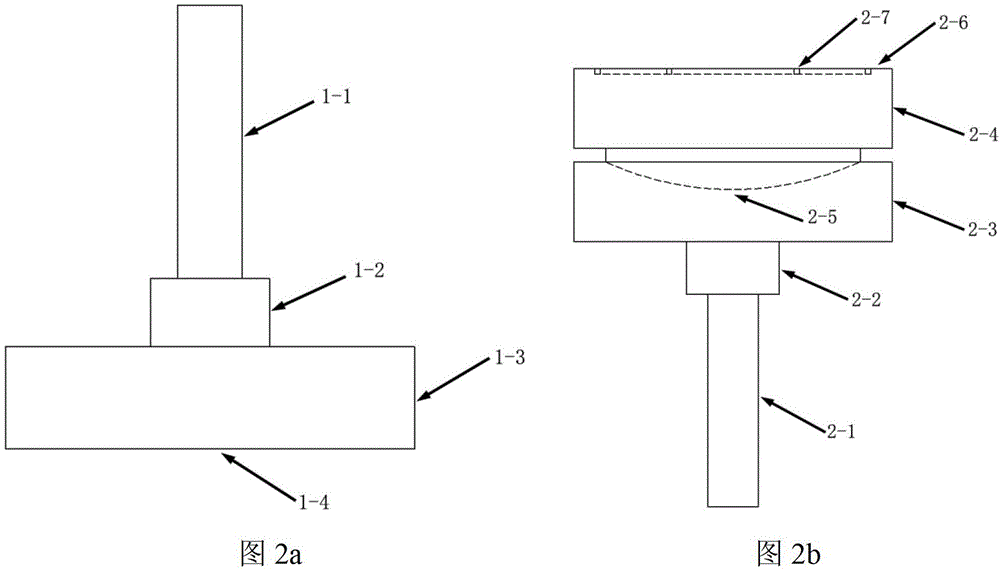

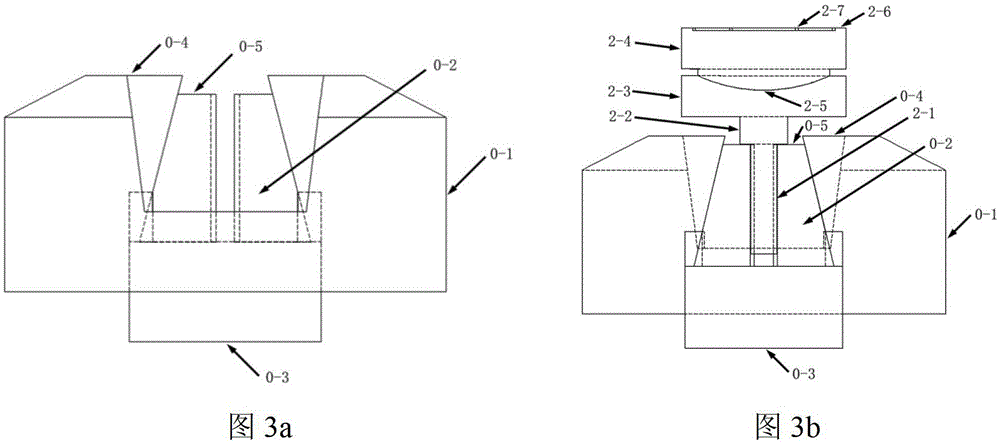

[0035] The upper part and the lower part of the anti-compression fixture of the present invention are respectively installed in the V-shaped groove of the wedge 0-2 of the MTS testing machine, and clamped, such as Figure 4 As shown; the specific installation process is as follows: First, insert the upper holding rod 1-1 of the upper part of the compression fixture into the V-shaped groove of the wedge 0-2 until the upper limit block 1-2 faces the upper holding rod 1 The surface of -1 is in contact with the top surface o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com