Apparatus for testing compression strength of sea ice

A technology of compressive strength and clamping, applied in the direction of applying stable tension/pressure to test the strength of materials, etc., can solve the problems of easy failure, poor equipment matching, complicated test preparation, etc., to achieve improved accuracy, compact connection, The effect of simple system structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

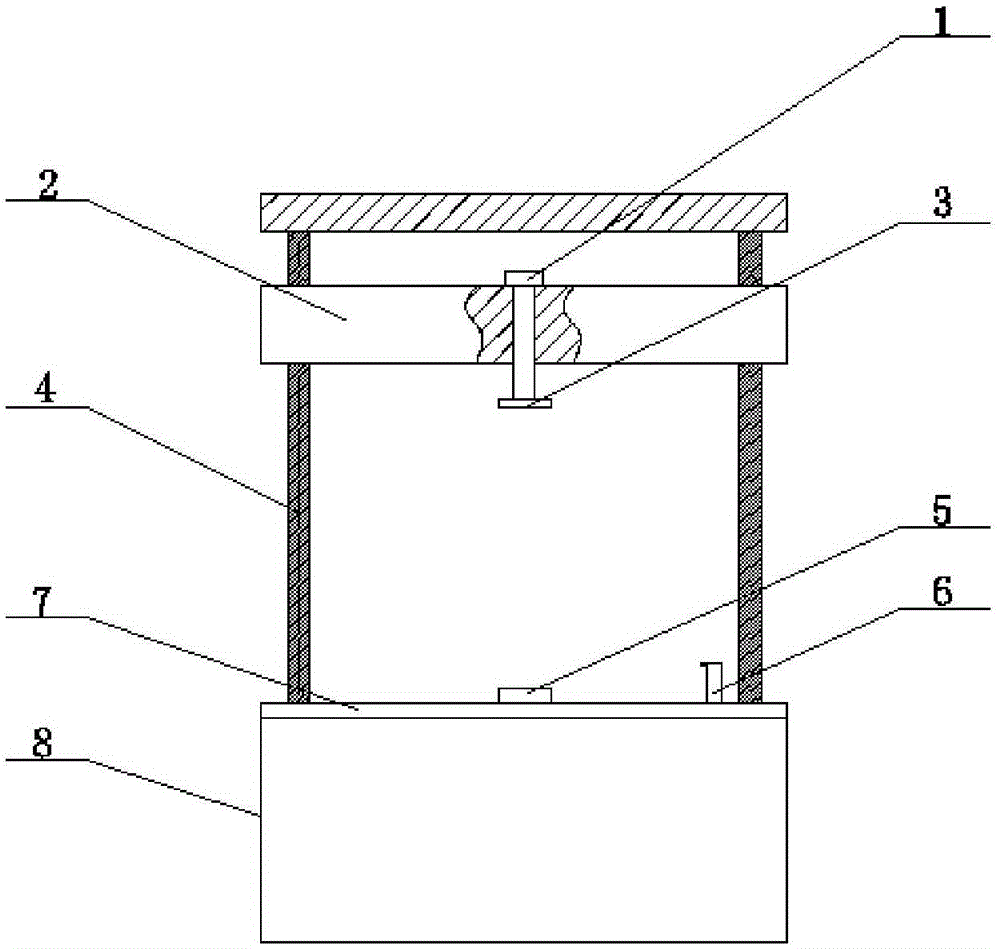

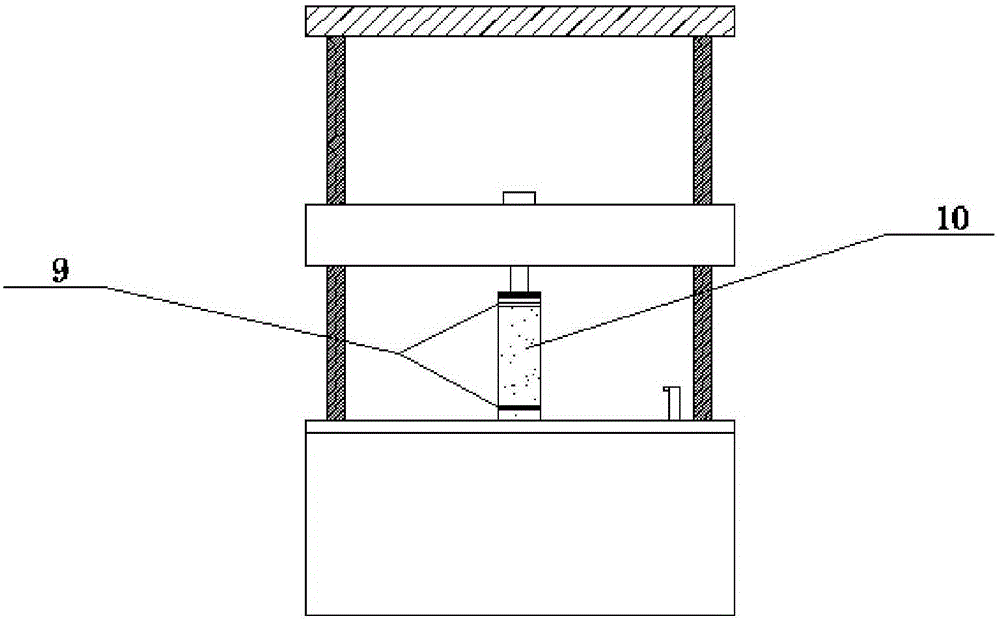

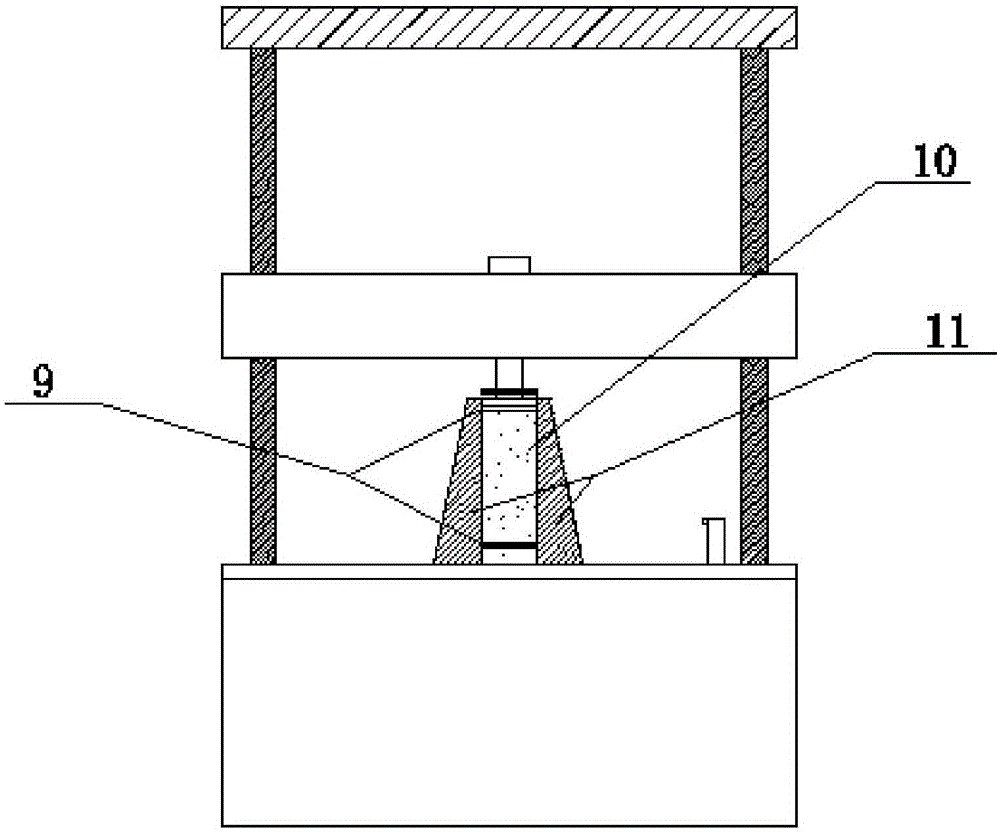

[0022] A device for testing the compressive strength of sea ice. The pressure test includes a uniaxial compression test method and a confining compression test method. The clamping methods for the sea ice sample 10 include the sea ice sample uniaxial compression clamping method and the sea ice The sample lateral compression clamping method, the sea ice sample 10 adopts a hexahedron, the cross section is square, and the height dimension direction is guaranteed to be 2.5 times the width. The sea ice pressure testing machine 12 is guaranteed to be placed on the level ground during the test. The sea ice pressure testing machine drives the movable beam 2 to move vertically up and down through the loading system. The maximum compression force of the sea ice pressure testing machine is 50KN. The sea ice collected on site was cut into the sea ice sample 10 required for the experiment.

[0023] The sea ice sample 10 clamping process is as follows: the upper and lower ends of the sea ic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com