Ambient preparation and control method of low-density SiO2 aerogel

A control method, airgel technology, applied in the direction of silica, silicon oxide, etc., can solve the problems of many influencing parameters and difficult process control, and achieve the effect of feasible process control, low cost, and simple compression strength monitoring method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

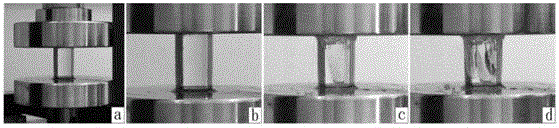

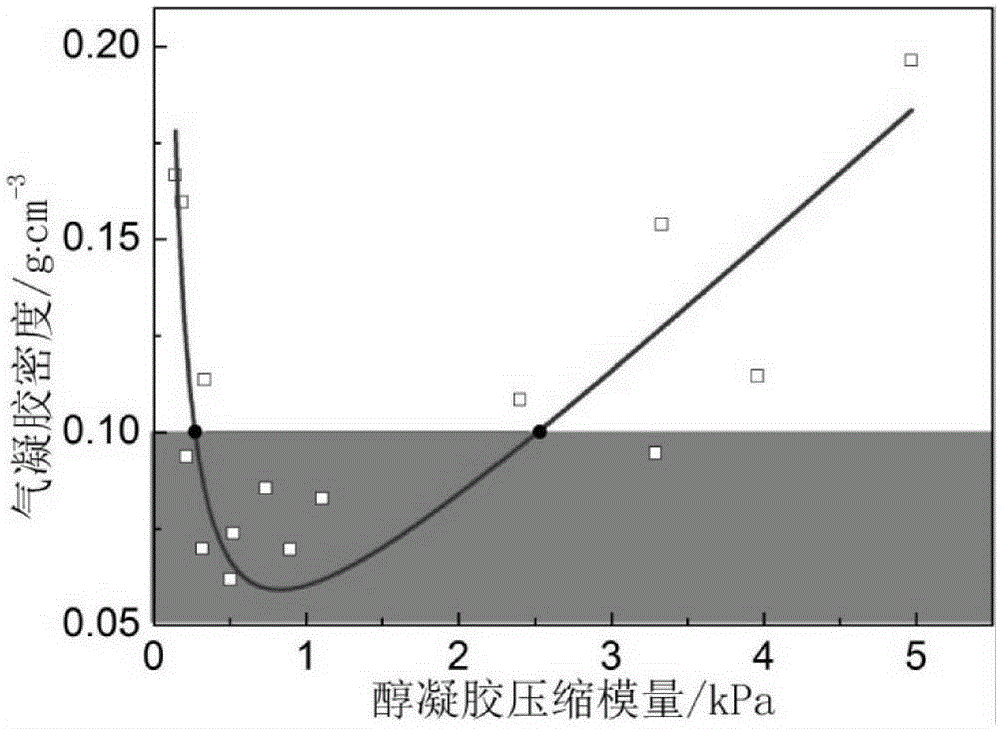

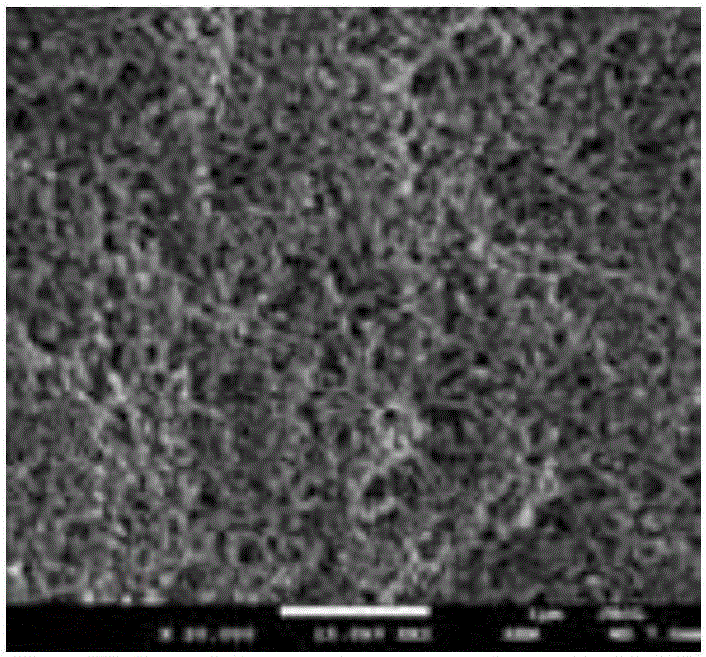

Image

Examples

Embodiment

[0060] The density is 62kg m -3 Hydrophobic SiO 2 The preparation control method of airgel is as follows:

[0061] Step 1, acid catalysis:

[0062] Mix ethyl orthosilicate with absolute ethanol, add deionized water and hydrochloric acid for acid catalysis, control the molar ratio of ethyl orthosilicate, absolute ethanol, deionized water and hydrochloric acid to 1:7:1:10 -5 ; Reaction obtains silica sol 1,

[0063] Step 2, base catalysis:

[0064] N,N-dimethylformamide, deionized water and ammonia water are mixed for base-catalyzed reaction to obtain silica sol 2; the molar ratio of the N,N-dimethylformamide, the deionized water and the ammonia water is 3×10 -4 :1:2×10 -3 .

[0065] Step 3, SiO 2 Alcohol gel preparation:

[0066] Mix the silica sol 1 obtained in step 1 and the silica sol 2 obtained in step 2, put them in a container, and let them stand for 0.5 to 48 hours to make SiO 2 alcohol gel;

[0067] Step four, the aging of alcohol gel:

[0068] Put the alcoh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com