Anti-destabilization universal clamp used for compression performance test of edge/central notch composite material laminated plate

A composite material layer, laminate technology, applied in the direction of analyzing materials, measuring devices, strength characteristics, etc., can solve the problems affecting the normal progress of the test, the bending instability of the laminate, and excessive test fixtures, etc., to achieve good anti-bending effect, The effect of uniform clamping force and improved accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

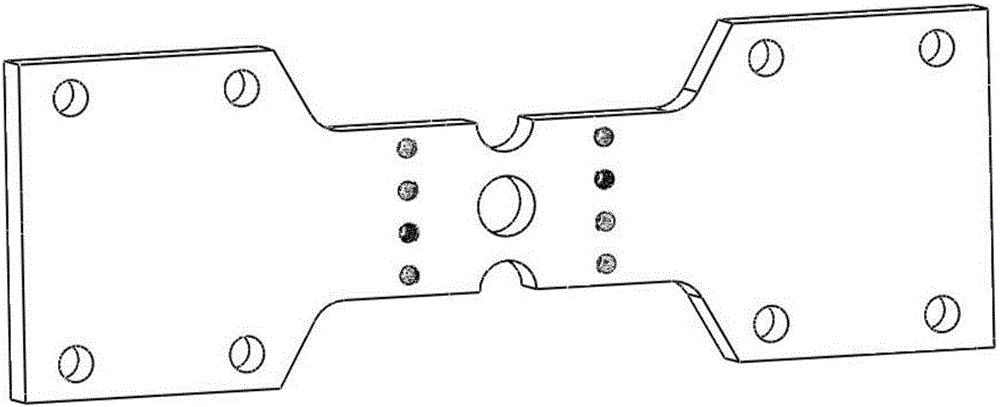

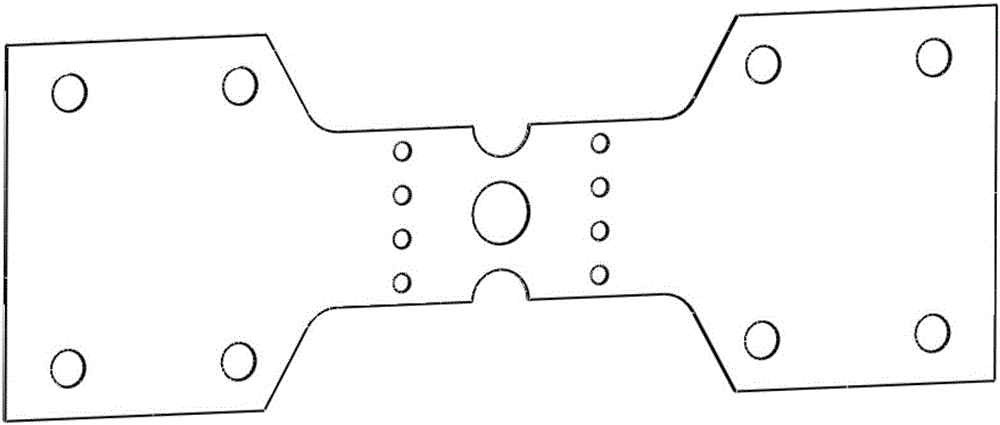

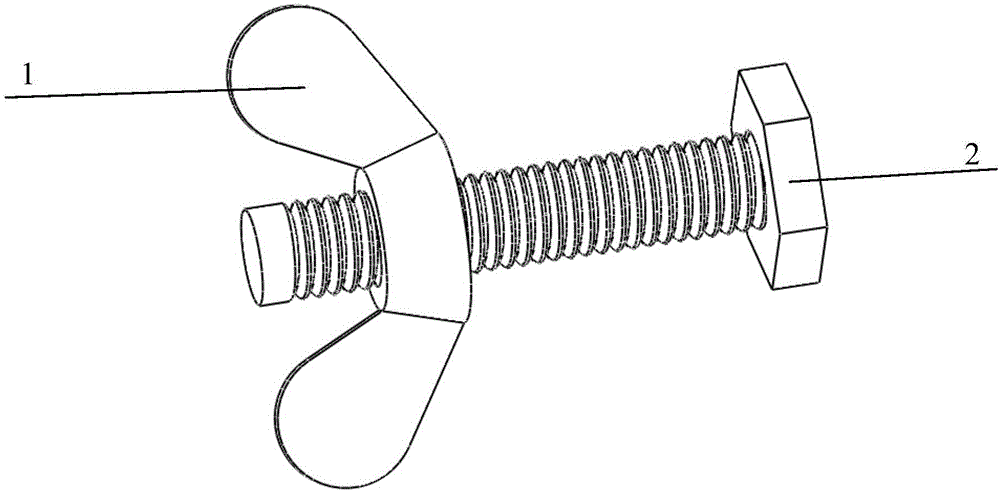

[0019] The present invention is a universal clamp for preventing instability for testing the compression performance of edge / center gap composite laminates. It is reinforced by dog-bone metal splints with edge openings and center openings, PA6 nylon sandwich, wing nuts and bolts and openings. Accessories and other components. in Image 6 with Figure 7 In the middle, the PA6 nylon sandwich 2 is placed on the upper and lower surfaces of the edge / center gap laminate 1, and the surface shape of the sandwich is the same as the laminate; the dog-bone splint 3 with edge opening and center opening is placed on the upper and lower nylon sandwich 2 Make the openings of the splint coincide with the gaps of the nylon sandwich and laminate; use 8 pairs of wing nuts and bolts 4 to fasten the dog-bone splint 3 to clamp the nylon sandwich 2 and the laminate 1. For edge-notched laminate specimens (e.g. Image 6 (Shown), using 2 pairs of opening reinforcement accessories, insert the semi-cylind...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com