An air-cooled compression condensing unit performance test system

A technology of condensing unit and test system, which is applied in the field of construction environment and equipment engineering, can solve the problems of high temperature of calorimeter, inaccurate measurement of heat transfer heat of heat pipe, and inability to realize heat balance of calorimeter, so as to achieve uniform distribution and reduce energy consumption. consumption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

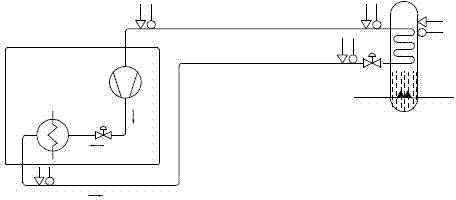

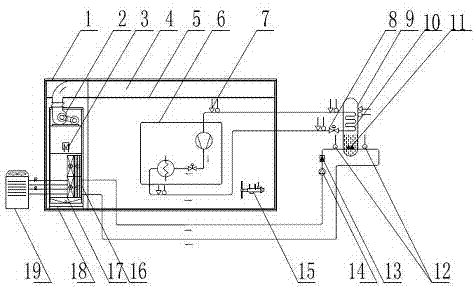

[0020] like figure 2 As shown, the test system consists of three parts: air circulation processing system, refrigerant circulation system and energy balance and metering system.

[0021] In the refrigeration system cycle, the high-temperature and high-pressure refrigerant liquid from the tested air-cooled compression condensing unit 6 is throttled through the throttle valve 8 to become a gas-liquid two-phase fluid, and then enters the evaporation coil in the calorimeter 9 10. The superheated steam heated by the second refrigerant returns to the tested air-cooled compression condensing unit 6 to complete the entire refrigeration cycle. In order to accurately calculate the cooling capacity of the air-cooled compression condensing unit, the pressure measuring point 7 and the temperature measuring point 12 are respectively set at the inlet and o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com