Compressor performance testing system

A test system, compressor technology, applied in pump testing, mechanical equipment, machines/engines, etc., can solve the problems of mechanical performance operation test, compressor operation reliability performance risk, inability to compressor performance detection and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

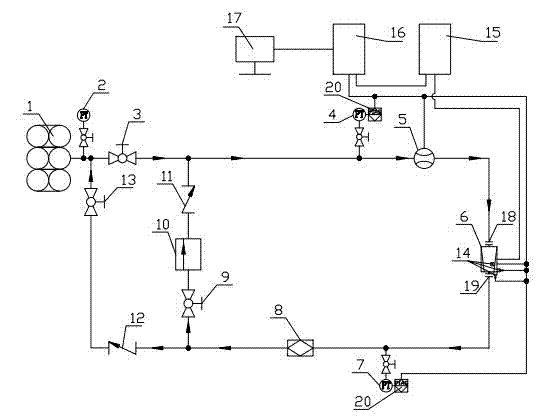

[0013] like figure 1 Shown shows a kind of compressor performance test system, comprises gas cylinder group 1, vibration detector 14, microprocessor 16, display 17, is provided with compressor inlet and compressor outlet on the compressor 6 to be tested, storage A ball valve 3 and a turbine flowmeter 5 are successively provided on the input pipeline between the gas cylinder group 1 and the compressor inlet, and a compressor inlet connection flange 18 connected to the compressor inlet is also provided on the described input pipeline; A filter 8, a one-way valve 12, and a ball valve 13 are sequentially provided on the output pipeline between the outlet and the gas cylinder group 1, and a compressor outlet connecting flange 19 connected to the compressor outlet is also provided on the output pipeline. ; Between the outlet of the compressor and the inlet of the compressor, a circulation connection pipeline is also connected, and a filter 8, a ball valve 9, a pressure regulating va...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com