A light-transmitting concrete preparation device and preparation method

A light-transmitting concrete and preparation device technology, applied in the direction of supply devices, manufacturing tools, ceramic molding machines, etc., can solve the waste of manpower and time for optical fiber arrangement and fixing, affect the appearance and durability of concrete, and produce low efficiency, etc. problems, to achieve the effect of shortening the construction period, reducing manpower costs, and high accuracy of layout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to better understand the present invention, the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

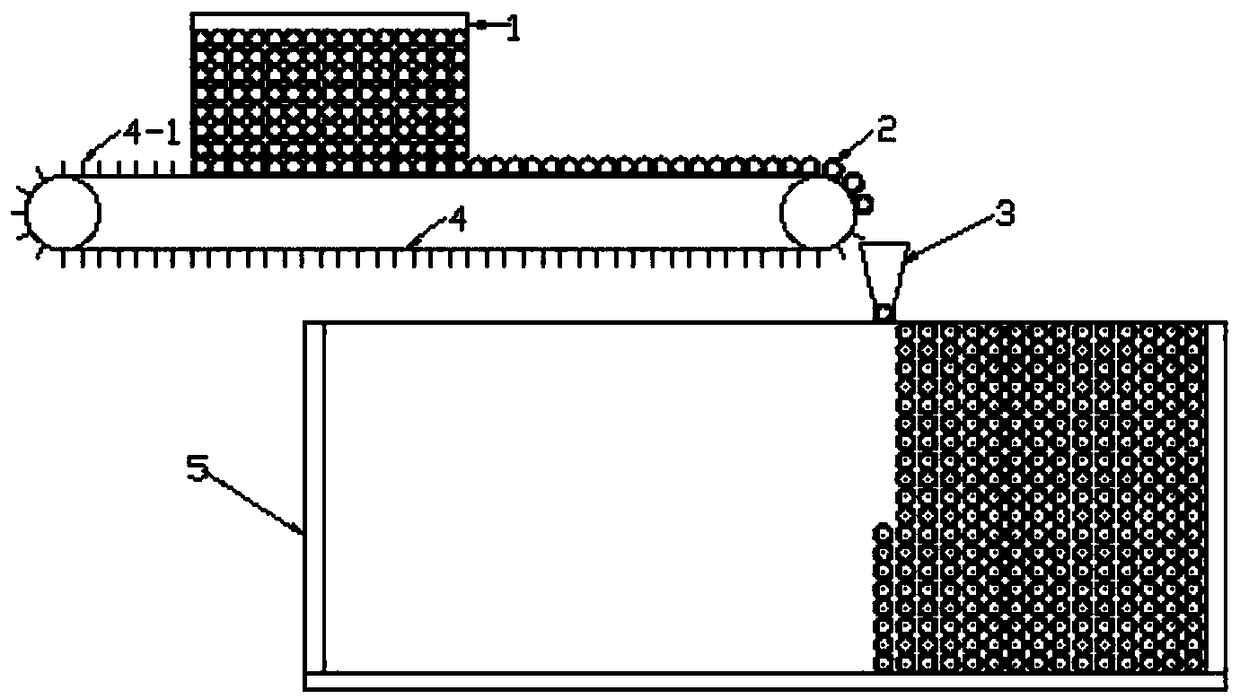

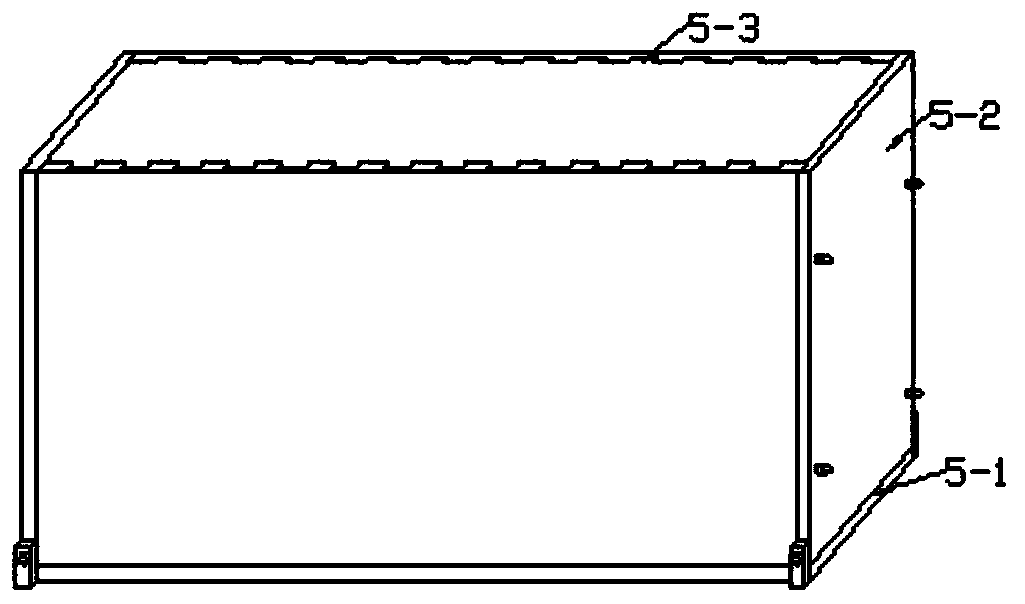

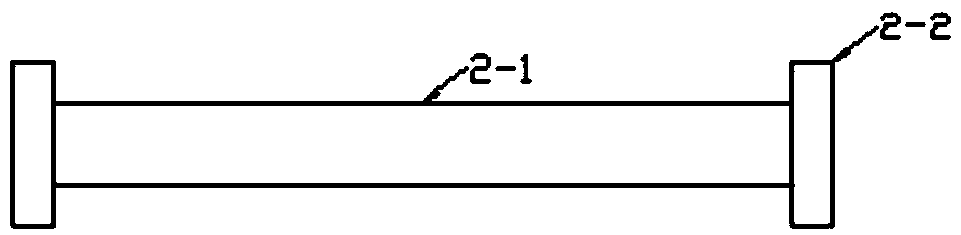

[0036] Such as figure 1 A light-transmitting concrete preparation device shown includes a light-transmitting medium storage bin 1, a forming mold 5 and a conveying device for transporting the light-transmitting medium 2. The bottom of the light-transmitting medium storage bin 1 has an outlet, and the light-transmitting medium The outlet of the medium storage bin 1 is located directly above the input end of the transmission device; the forming mold 5 is provided with an installation groove, which is compatible with the light-transmitting medium 2; the output end of the transmission device is located directly above the installation groove; The axis of the transparent medium 2 is always perpendicular to the conveying direction of the conveying device.

[0037] The transmission device includes a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com