Drum winding device

A technology of winding device and drum, which is applied in the direction of transportation and packaging, drill pipes, drill pipes, etc., can solve the problems of adjusting the height of carbon fiber rods, no automatic carbon fiber rod arrangement device, and carbon fiber rods are not neat.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The above and other technical features and advantages of the present invention will be clearly and completely described below with reference to the accompanying drawings. Obviously, the described embodiments are only some embodiments of the present invention, but not all embodiments.

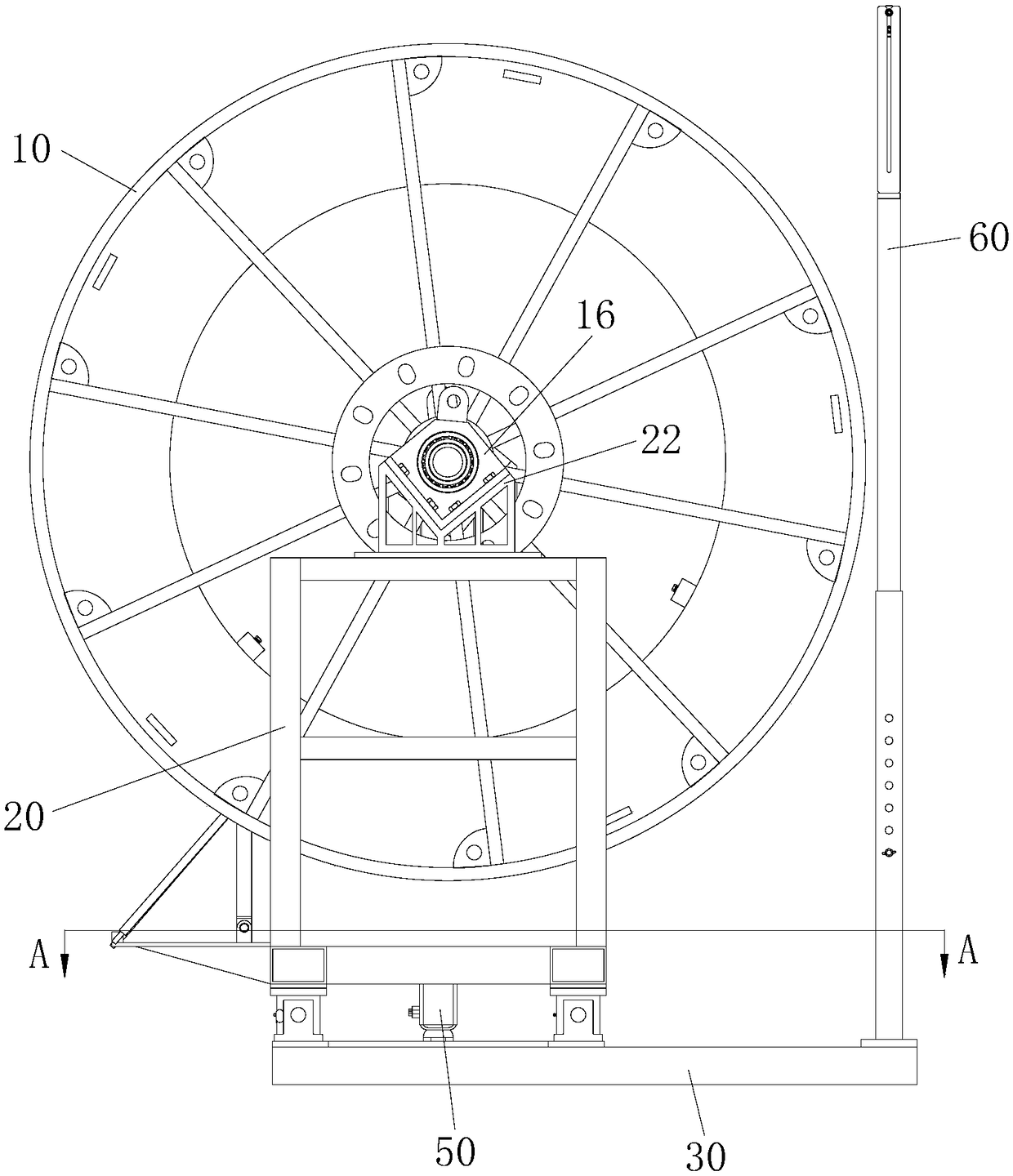

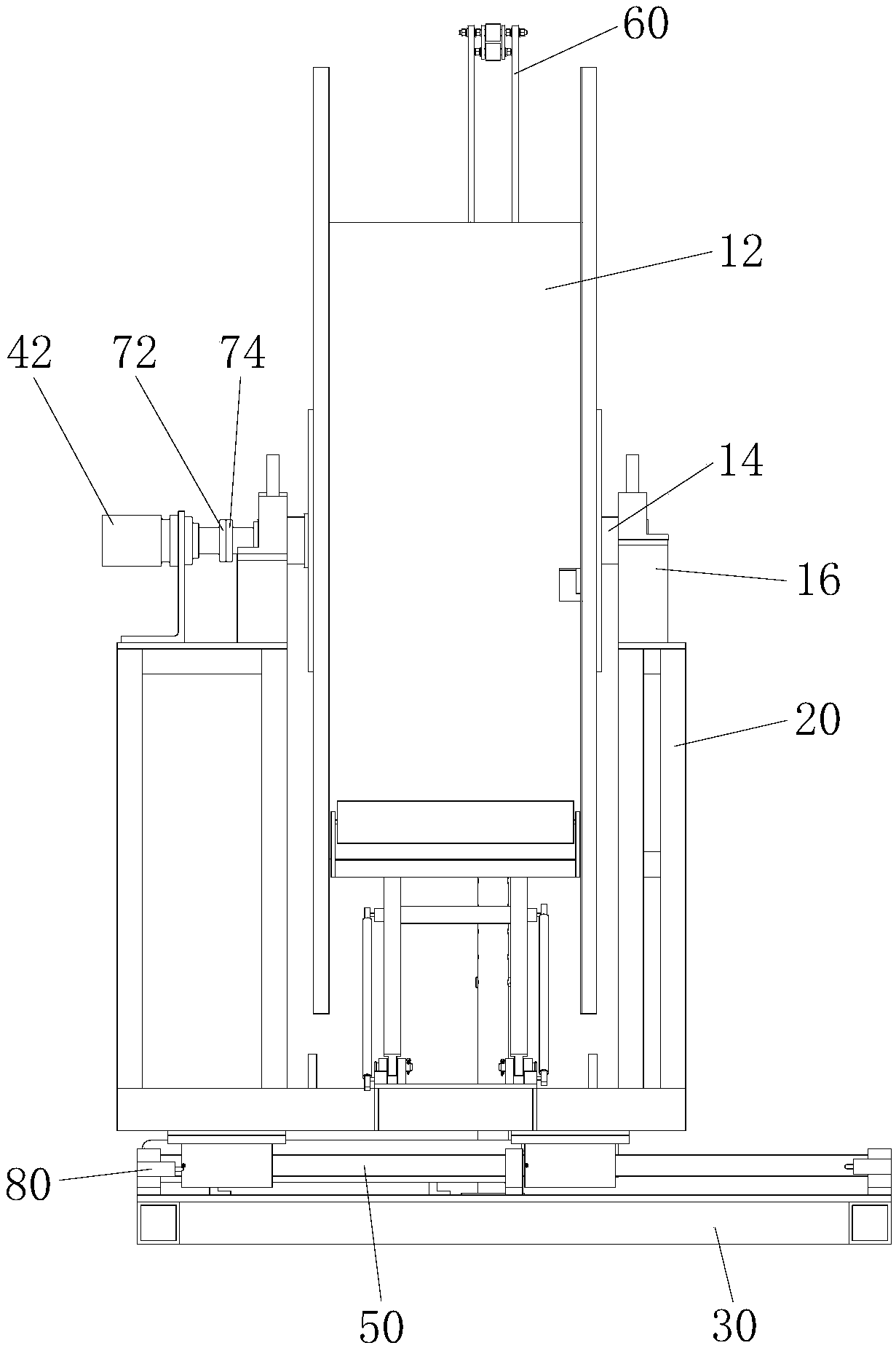

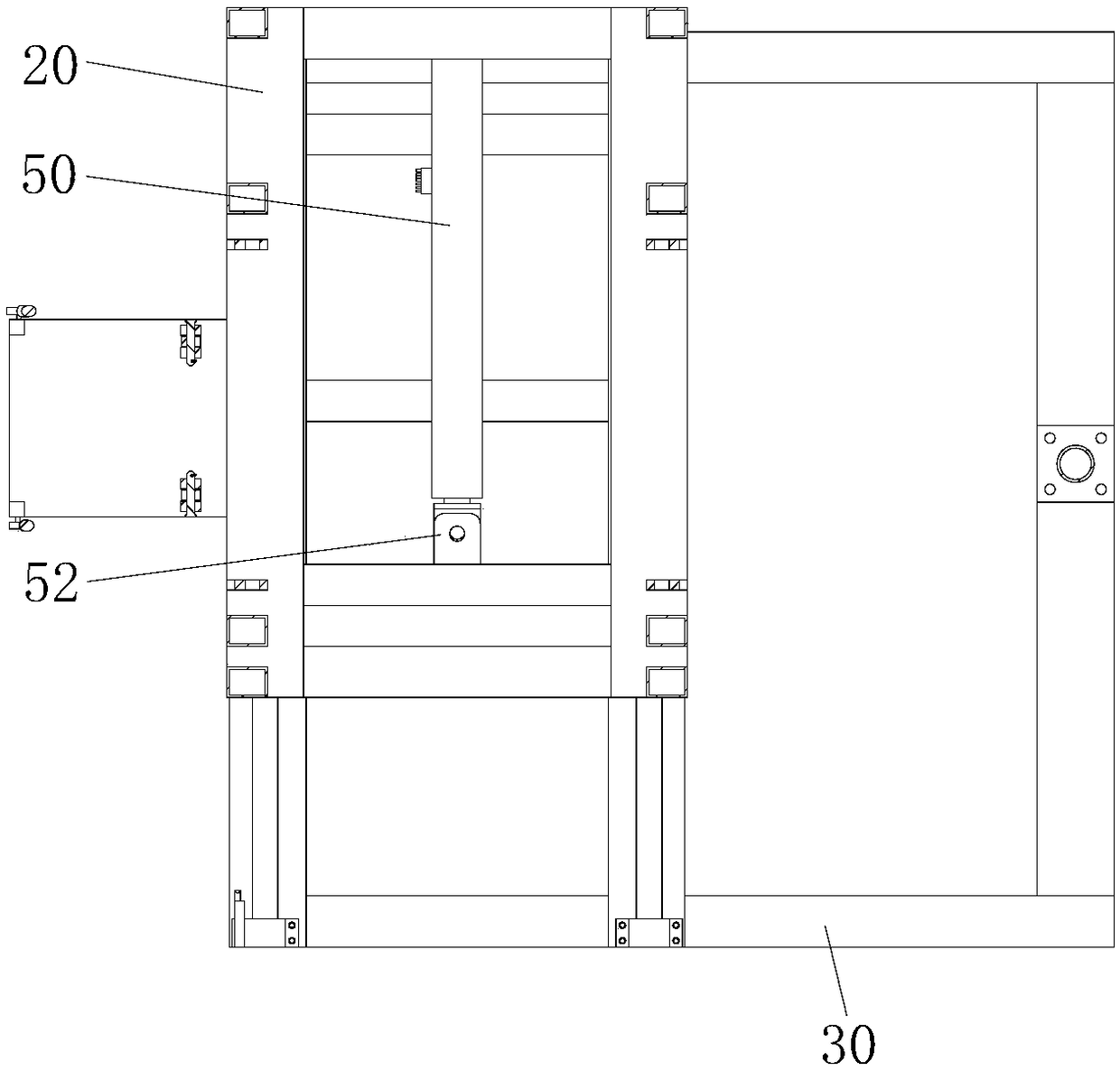

[0043] see figure 1 and figure 2 As shown, the present invention provides a drum winding device, which includes a drum body assembly 10, a drum support base 20, a base 30, a motor 42 with an output shaft, and an electric cylinder 50 with a push rod. The drum body assembly 10 includes a vertical drum 12 and a drum shaft 14. The drum shaft 14 runs through the drum 12 along the center of the drum 12; It can be placed on the base 30 so as to be slidable in the horizontal direction. The output shaft of the motor 42 is connected to the drum shaft 14 and drives the drum shaft 14 to rotate. see image 3 As shown, the electric cylinder 50 is horizontally arranged on the base 30, the telescopi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com