Method for rapidly improving machining efficiency of aviation beam type products and device of method

A processing efficiency and aviation technology, applied in metal processing equipment, metal processing machinery parts, manufacturing tools, etc., can solve the problems of restricting the development of national defense equipment manufacturing industry, complex procedures, low efficiency, etc., to reduce repeated clamping work, shorten the Process flow and cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The following non-limiting examples illustrate the invention.

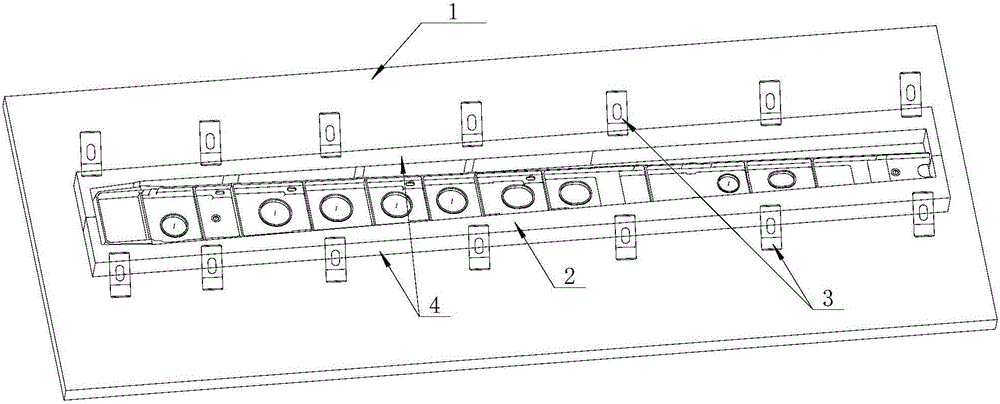

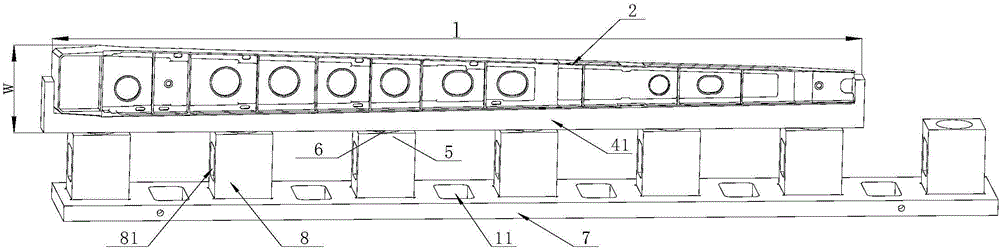

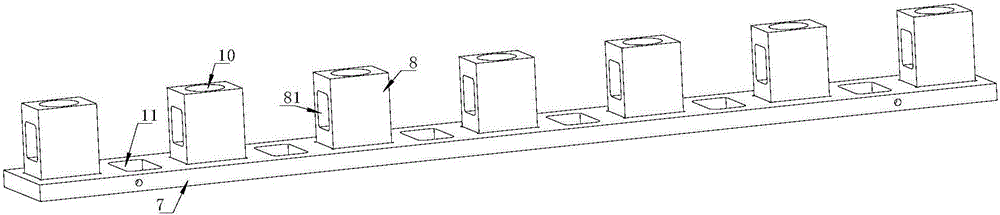

[0043] refer to Figure 2 to Figure 8 As shown, a method for rapidly improving the processing efficiency of aviation beam products is to use the zero point positioning device to vertically clamp the aviation beam parts 2 to be processed, and carry out machine tool processing in the state of vertical clamping; The clamping tool is used to clamp and fix the aviation beam part 2 to be processed with its length direction l horizontally oriented and width direction w vertically oriented (that is, the vertical state of vertical clamping); the clamping tool includes zero point The positioning device and the positioning and fixing device, the zero point positioning device includes several corresponding zero point locators 5 and positioning joints 6, the positioning and fixing device includes a base plate 7 and several support blocks 8 fixed on the base plate 7; The bottom edge (i.e. the bottom frame 41) in the len...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com