Aluminum foam sandwich plate with gradient interface and manufacturing method thereof

A manufacturing method and technology of foamed aluminum, which are applied in the field of porous metal materials and layered composite materials, can solve the problems of shearing and tearing damage of foamed aluminum, discontinuous structure and composition, uneven interface stress, etc. Wide selection of materials, combined with high-quality effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

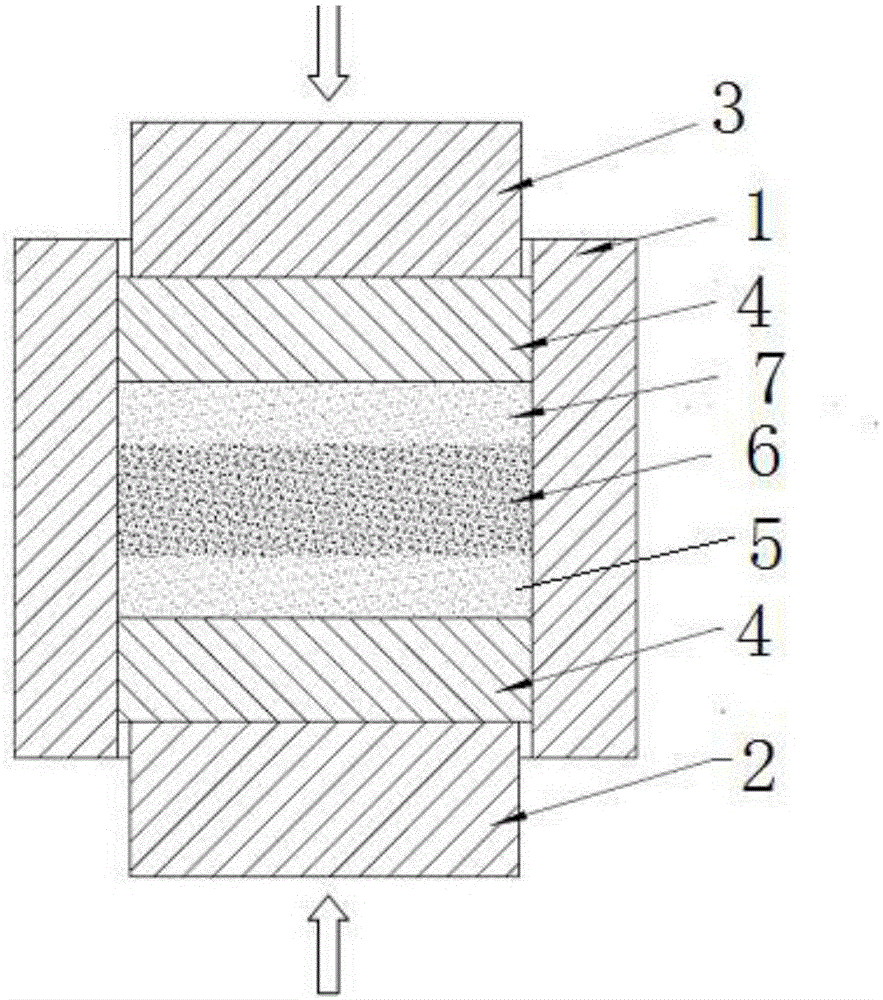

[0031] The process of preparing an aluminum foam sandwich panel with a total thickness of 29mm, a panel thickness of 2.5mm, and a foam aluminum core layer thickness of 24mm is as follows:

[0032] (1) Weigh 139.3g of Al-11Si alloy powder with a particle size of 150 mesh (density of 2.65g / cm 3 ), particle size is 325 purpose titanium hydride powder 0.7g, makes the massfraction of titanium hydride powder and aluminum alloy powder be respectively 0.5wt% and 99.5%), all packs in the barrel type mixing tank, mixes 8 on the mixer Hours, made into mixed powder;

[0033] (2) Weigh two portions of 3003Al alloy powder with a particle size of 150 mesh, each 90g (density 2.73g / cm3 ), the total weight of the powder (i.e. the total weight of the sandwich panel sample) 320g;

[0034] (3) Made of heat-resistant stainless steel figure 1 For the mold shown, the cavity size of the mold is 55mm (width) × 200mm (length) × 150mm (height). 90g of 3003Al alloy powder, 140g of mixed powder and 90g o...

Embodiment 2

[0039] The process of preparing an aluminum foam sandwich panel with a total thickness of 10.6mm, a panel thickness of 0.8mm, and a foam aluminum core layer thickness of 9mm is as follows:

[0040] (1) Weigh 261.1g of Al-10Si-0.5Mg alloy powder with a particle size of 150 mesh (density of 2.65g / cm 3 ), particle size is 325 purpose titanium hydride powder 1.3g, makes the massfraction of titanium hydride powder and aluminum alloy powder be respectively 0.5wt% and 99.5%), all packs in the barrel type mixing tank, mixes 8 on the mixer Hours, made into mixed powder;

[0041] (2) Take two parts of particle size respectively and be 118.8g each of pure aluminum powder of 150 mesh (density is 2.7g / cm 3 ). The total weight of the powder (i.e. the total weight of the sandwich panel sample) is 500g;

[0042] (3) Made of heat-resistant stainless steel figure 1 For the mold shown, the cavity size of the mold is 55mm (width) × 200mm (length) × 150mm (height), and 118.8g of pure aluminum ...

Embodiment 3

[0047] The process of preparing an aluminum foam sandwich panel with a total thickness of 40mm, a panel thickness of 3mm, and a foam aluminum core layer thickness of 34mm is as follows:

[0048] (1) Weigh 400g of 6061Al alloy powder with a particle size of 150 meshes (density of 2.7g / cm 3 ), particle size is 325 purpose titanium hydride powder 4g, makes the massfraction of titanium hydride powder and aluminum alloy powder be respectively 1.0wt% and 99%), all packs in the barrel type mixing tank, mixes 16 hours on the mixer , made into mixed powder;

[0049] (2) Weigh two parts of Ti-6Al-4V alloy powder with a particle size of 150 meshes, each 292g (density is 4.43g / cm 3 ). The total weight of the powder (i.e. the total weight of the sandwich panel sample) is 988g;

[0050] (3) Made of heat-resistant stainless steel figure 1 For the mold shown, the cavity size of the mold is 55mm (width) × 200mm (length) × 150mm (height), and 292g of Ti-6Al-4V alloy powder, 404g of mixed po...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com