Hyperbranched polyester hot-melt-type polyurethane adhesive for weaving and preparation method thereof

A technology of polyurethane adhesive and hyperbranched polyester, which is applied in the direction of polyurea/polyurethane adhesive, adhesive type, non-polymer adhesive additive, etc., can solve the problems of rare research and achieve improvement The degree of branching, good adhesion, and the effect of increasing adhesion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

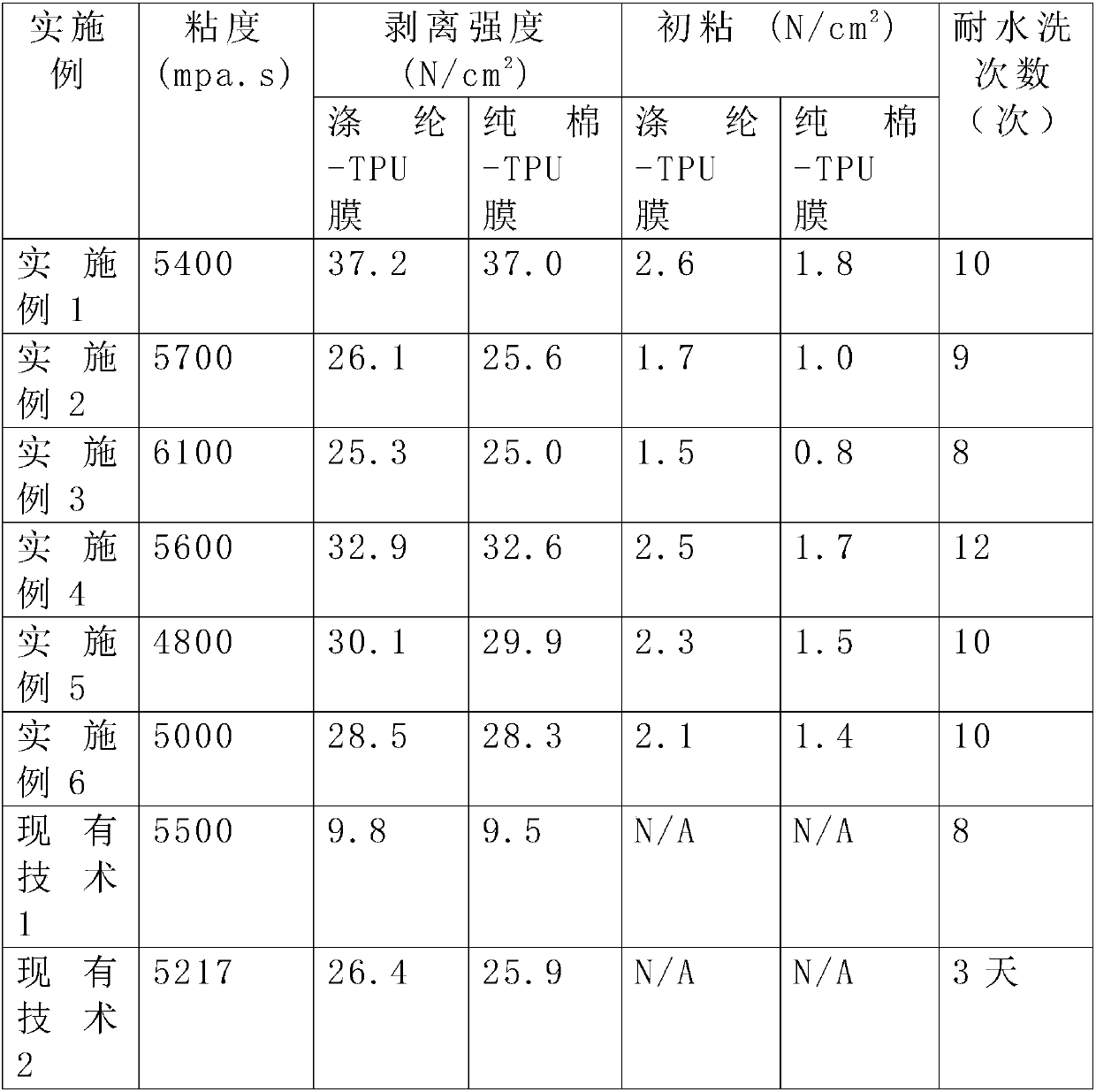

Examples

Embodiment 1

[0026] Preheat the reactor to 50°C, after drying, put 39.7g of 4,4'-diphenylmethane diisocyanate and 22.9g of polyether GE-220A into it by vacuum, and then control the temperature at 60°C for 3h under vacuum. Rapidly lower the temperature to 55°C, put in 27.3g of polyether GE-204 and 6.7g of highly branched polyester polyol SOVERMOL1080 by vacuum, and then continue the reaction under vacuum for 2h. Adding 3.4g mass ratio after the completion of the reaction is a silane coupling agent and a light stabilizer of 1:1, stops stirring, and removes bubbles in a vacuum to obtain hyperbranched polyester hot-melt polyurethane adhesive for textiles.

Embodiment 2

[0028] The reactor was preheated to 50°C, and after drying, 38.3g of 4,4'-diphenylmethane diisocyanate and 25.6g of polyether GE-210 were put in by vacuum, and then the temperature was controlled at 80°C for 3 hours under vacuum. The temperature was rapidly lowered to 55°C, and 25.6g of polyether GE-204 and 7.8g of highly branched polyester polyol SOVERMOL760 were put in by vacuum, and then the reaction was continued for 3h under vacuum. After the reaction, add 2.7g of silane coupling agent and light stabilizer with a mass ratio of 1:0.7, stop stirring, and vacuum remove air bubbles to obtain hyperbranched polyester hot-melt polyurethane adhesive for textile.

Embodiment 3

[0030]Preheat the reactor to 50°C. After drying, put 29.8g of 4,4'-diphenylmethane diisocyanate and 30.7g of polyether GE-204 into it by vacuum, and then control the temperature at 70°C for 3h under vacuum. Rapidly lower the temperature to 55°C, put in 30.7g of polyether GE-210 and 5.7g of highly branched polyester polyol SOVERMOL1092 by vacuum, and then continue the reaction under vacuum for 2.5h. Adding 3.1g mass ratio after completion of the reaction is a silane coupling agent and a light stabilizer of 1:0.6, stops stirring, and removes air bubbles in a vacuum to obtain a hyperbranched polyester hot-melt polyurethane adhesive for textiles.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com