Rapid clamping method and device suitable for discrete multi-station production mode

A production mode, multi-station technology, used in metal processing equipment, positioning devices, clamping and other directions, can solve the problems of large differences in product structure, large repetitive workload, poor integration of coordinated operations, etc., to achieve product consistency Good, repeatable positioning accuracy, the effect of efficient manufacturing methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The following non-limiting examples illustrate the invention.

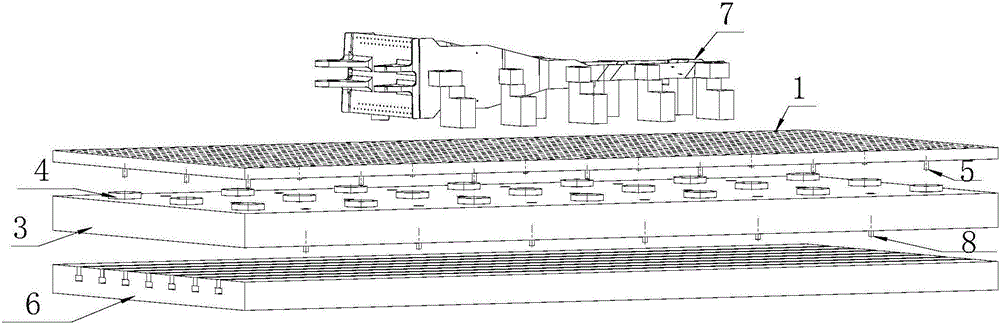

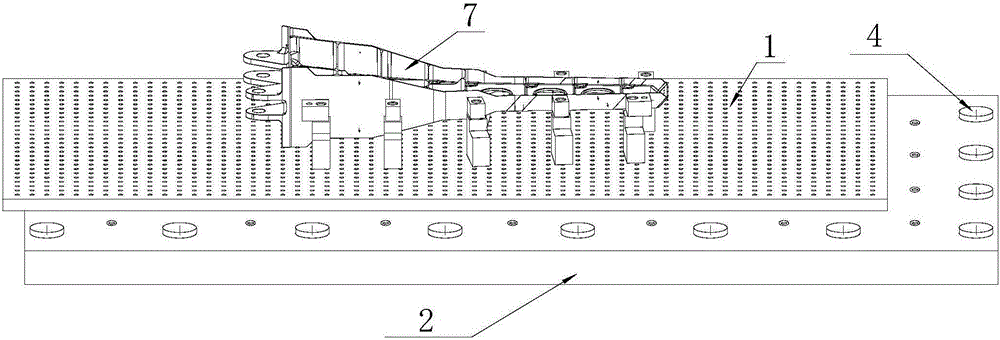

[0046] refer to Figure 1-9 As shown, a fast clamping method suitable for discrete multi-station production mode, using the external clamping workstation for clamping and alignment, and then processing on the processing machine:

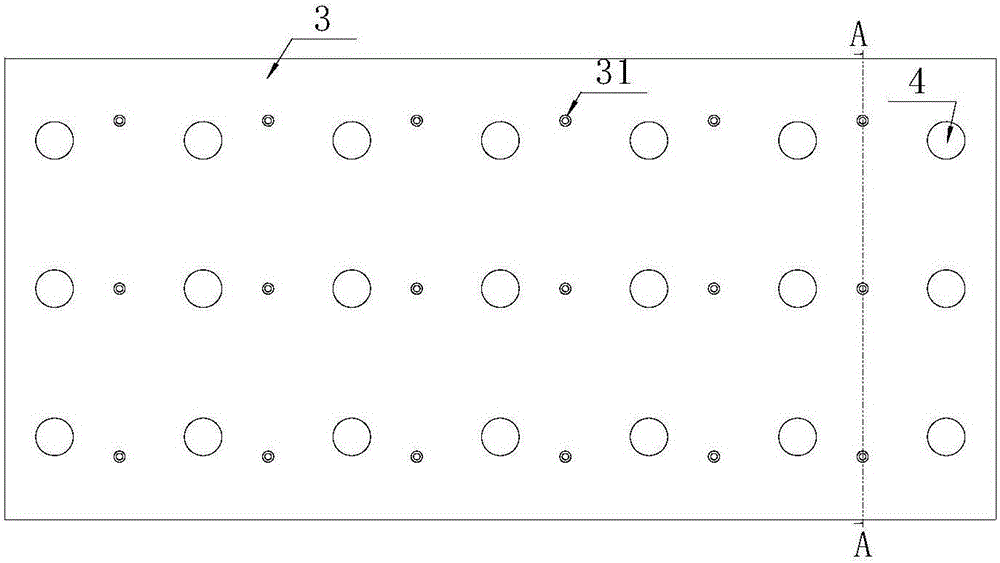

[0047] Processing machine tool (machining center): the processing machine tool includes a machine tool workbench 6, and a machine tool substrate 3 detachably fixed on the machine tool workbench 6, and a number of zero point locators 4 are arranged on the machine tool substrate 3;

[0048] External clamping workstation: The external clamping workstation includes a workbench, a zero point positioning device, a supporting plate 1 and an external clamping base plate 2, the zero point positioning device includes a zero point positioner 4 and a positioning joint 5, and the supporting plate 1 is equipped with a workpiece clamping and fixing Hole 11, a number of positioning joints 5 are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com