Polyimide film sintered powder mica bend coated flat copper cord and manufacturing process thereof

A technology of polyimide film and powder mica tape, which is applied in the direction of mica, cable/conductor manufacturing, plastic/resin/wax insulator, etc., and can solve the problems affecting the mechanical properties and high frequency output of sintered copper flat wire wrapped with mica tape Power fluctuations, core surface temperature fluctuations, etc., to avoid deterioration of mechanical properties, reduce fluctuations in core surface temperature, and improve the quality of fusion sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

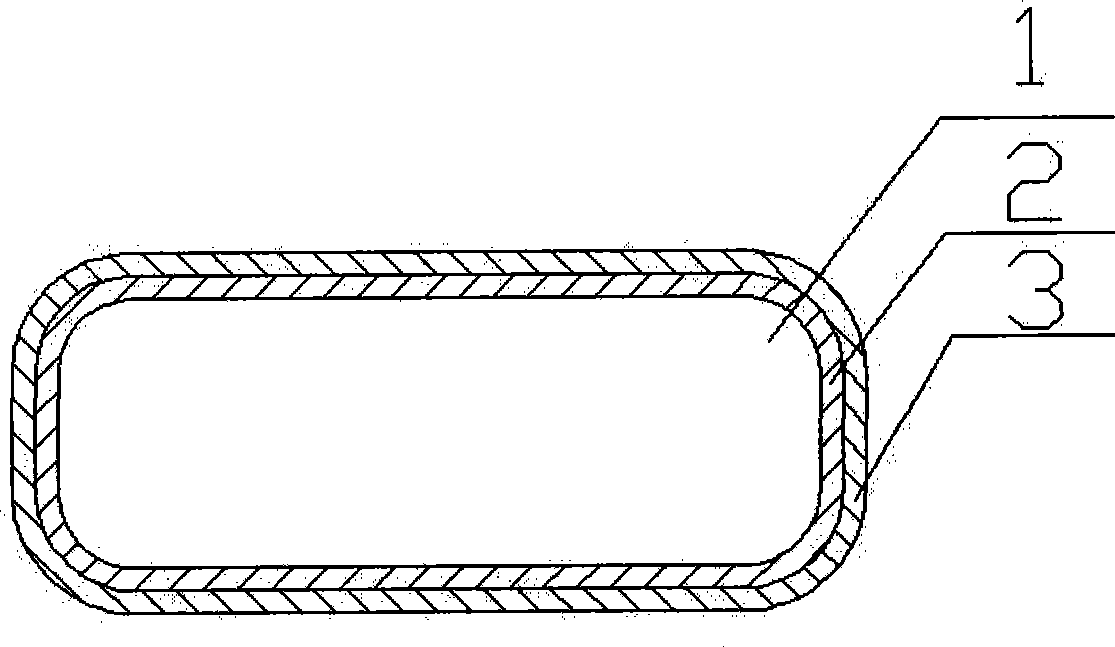

[0021] by attaching figure 2 , 3 It can be known that the present invention is a polyimide film sintered powder mica tape wrapped copper flat wire and its manufacturing method. The polyimide film sintered powder mica tape wrapped copper flat wire is composed of insulating material and metal wire, there are two layers of insulating material outside the metal wire 1, and the inner layer in contact with the metal wire is polyimide film 2. A mica tape 3 is wrapped around the polyimide film. The polyimide film is a polyimide-fluorine 46 film. After high-frequency heating, melting and sealing, the film and the metal wire, and the film and the film are firmly bonded into a whole.

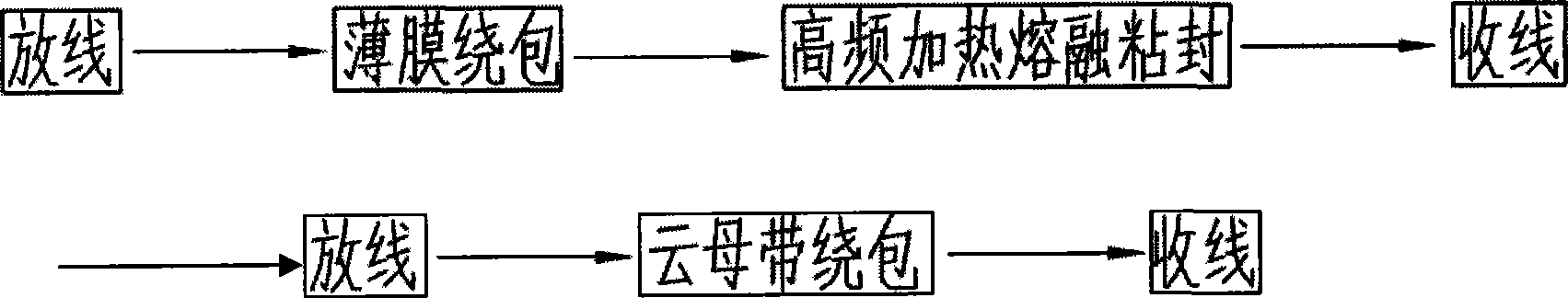

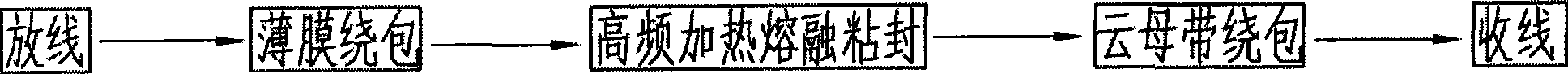

[0022] The manufacturing process of the polyimide film sintered powder mica tape wrapped copper flat wire comprises the following steps:

[0023] 1) Lay out the copper flat wir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com