Intrinsic conductive elastomer, preparation method thereof and flexible device

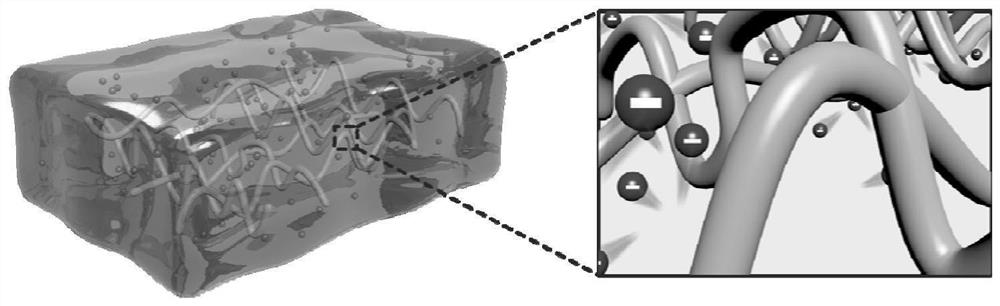

An intrinsically conductive and elastomer technology, applied in the field of materials, can solve the problems of leakage, complex compound method of liquid conductive fillers, limited application scenarios, etc., and achieve the effects of high stretching, excellent stability and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

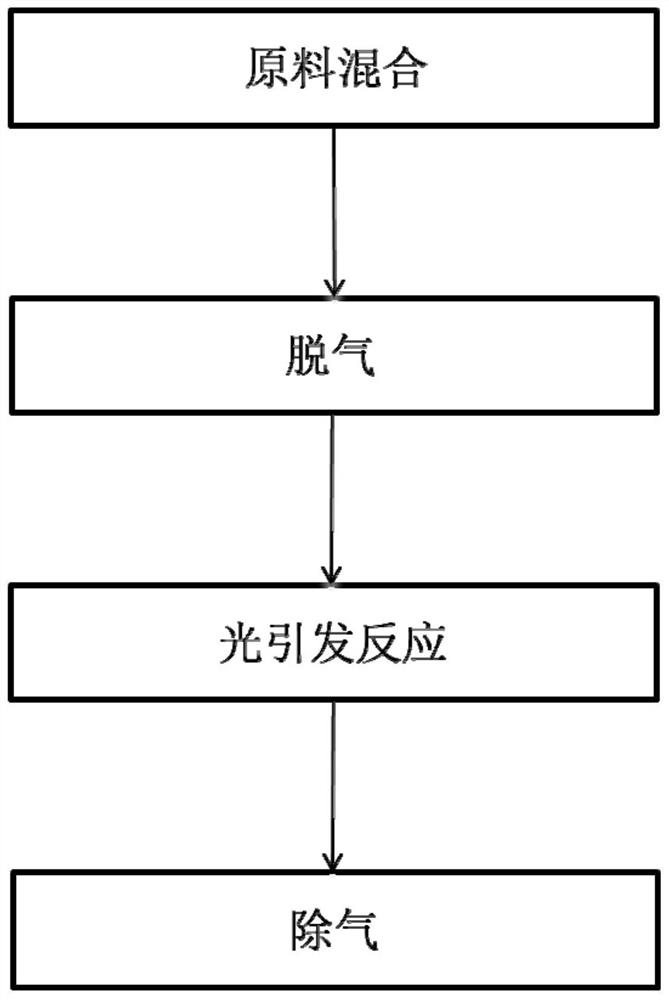

[0051] A preparation method of the intrinsically conductive elastomer, comprising:

[0052] mixing raw materials including functional ionic liquid monomers, comonomers, crosslinking agents and initiators, and reacting to obtain the intrinsically conductive elastomer;

[0053] The functional ionic liquid monomers include ionic liquid monomers with a glass transition temperature less than or equal to 30°C and containing C=C double bonds and bistrifluoromethylsulfonimide groups, and the comonomers include acrylates One or more of monomers, acrylamide monomers, styrene monomers and vinyl monomers.

[0054] In some optional embodiments, the functional ionic liquid monomers include imidazole ionic liquid monomers, pyridine ionic liquid monomers, pyrrole ionic liquid monomers, piperidine ionic liquid monomers, quaternary ammonium salts One or more of ionic liquid monomers and quaternary phosphonium ionic liquid monomers;

[0055] In some optional embodiments, the imidazole ionic li...

Embodiment 1

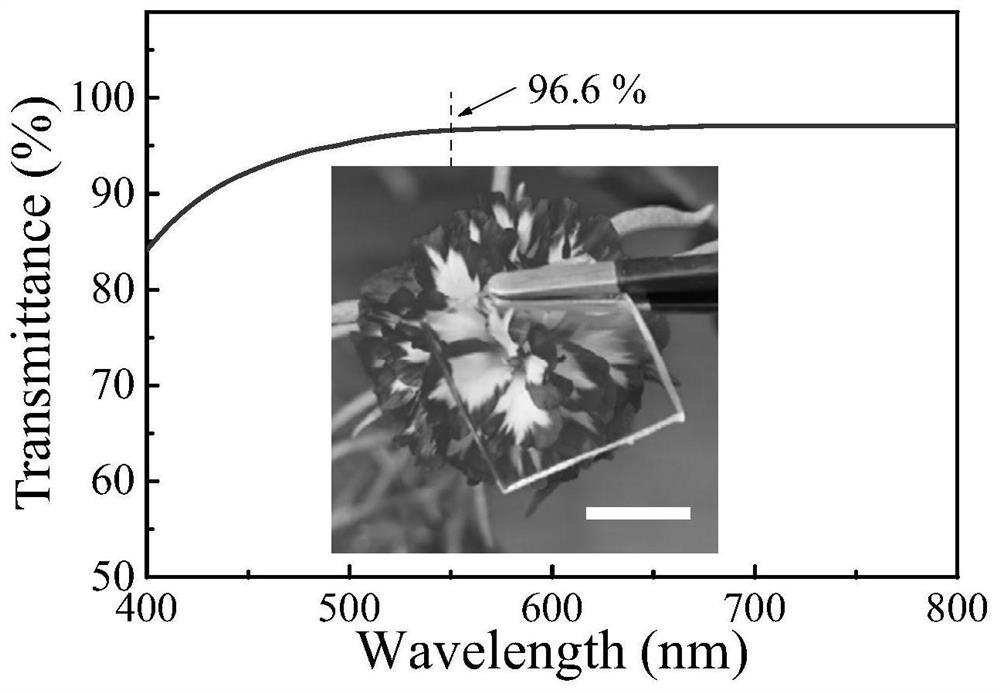

[0083] 0.5g ionic liquid monomer 1-(6-(acryloyloxy)-hexyl)-3-methylimidazolium trifluoromethylsulfonimide salt ([EIC6A][TFSI]), 0.5g copolymerized monomer Bulk butyl acrylate (BA), 1.4 mg crosslinker poly(ethylene glycol) diacrylate (PEGDA, Mn=575) and 4.9 mg photoinitiator 1-hydroxy-cyclohexyl phenyl ketone (photoinitiator 184 ) to mix, fully stir evenly to form a precursor fluid. Put the homogeneously mixed precursor liquid into the vacuum box, the vacuum degree is 0.1bar, and degas for 30s. Inject the degassed precursor liquid into the assembled glass sheet-silica gel pad-glass sheet sandwich cavity (the glass sheet is coated with a release film), and put it into a vacuum cross-linking box. Put the mold that has been injected with the precursor fluid into the ultraviolet cross-connection box, and the power density is 50mW / cm 2 , cross-linked for 30min. After the reaction is over, the glass mold is disassembled, and the intrinsically conductive elastomer is taken out. Th...

Embodiment 2

[0087] 0.5 g of ionic liquid monomer N-vinylpyridine bistrifluoromethylsulfonimide salt (VPyTFSI), 0.5 g of comonomer butyl methacrylate (BMA), 1.4 mg of cross-linking agent ethylene glycol diacrylic acid Methyl ester (EGDMA) and 4.9mg photoinitiator 2, 4, 6 (trimethylbenzoyl) diphenyl phosphine oxide were mixed, and fully stirred evenly to form a precursor liquid. Put the homogeneously mixed precursor liquid into the vacuum box, the vacuum degree is 0.1bar, and degas for 30s. Inject the degassed precursor liquid into the assembled glass sheet-silica gel pad-glass sheet sandwich cavity (the glass sheet is coated with a release film), and put it into a vacuum cross-linking box. Put the mold that has been injected with the precursor fluid into the ultraviolet cross-connection box, and the power density is 50mW / cm 2 , cross-linked for 30min. After the reaction is over, the glass mold is disassembled, and the self-healing intrinsically conductive ion conductor is taken out. The...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com