Cloth cleaning machine

A cleaning machine and cloth technology, applied in the field of machinery, can solve the problems of dismantling and replacing cloth for a long time, reducing production efficiency, etc., to achieve the effect of continuous online cleaning, improving production efficiency, and saving process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

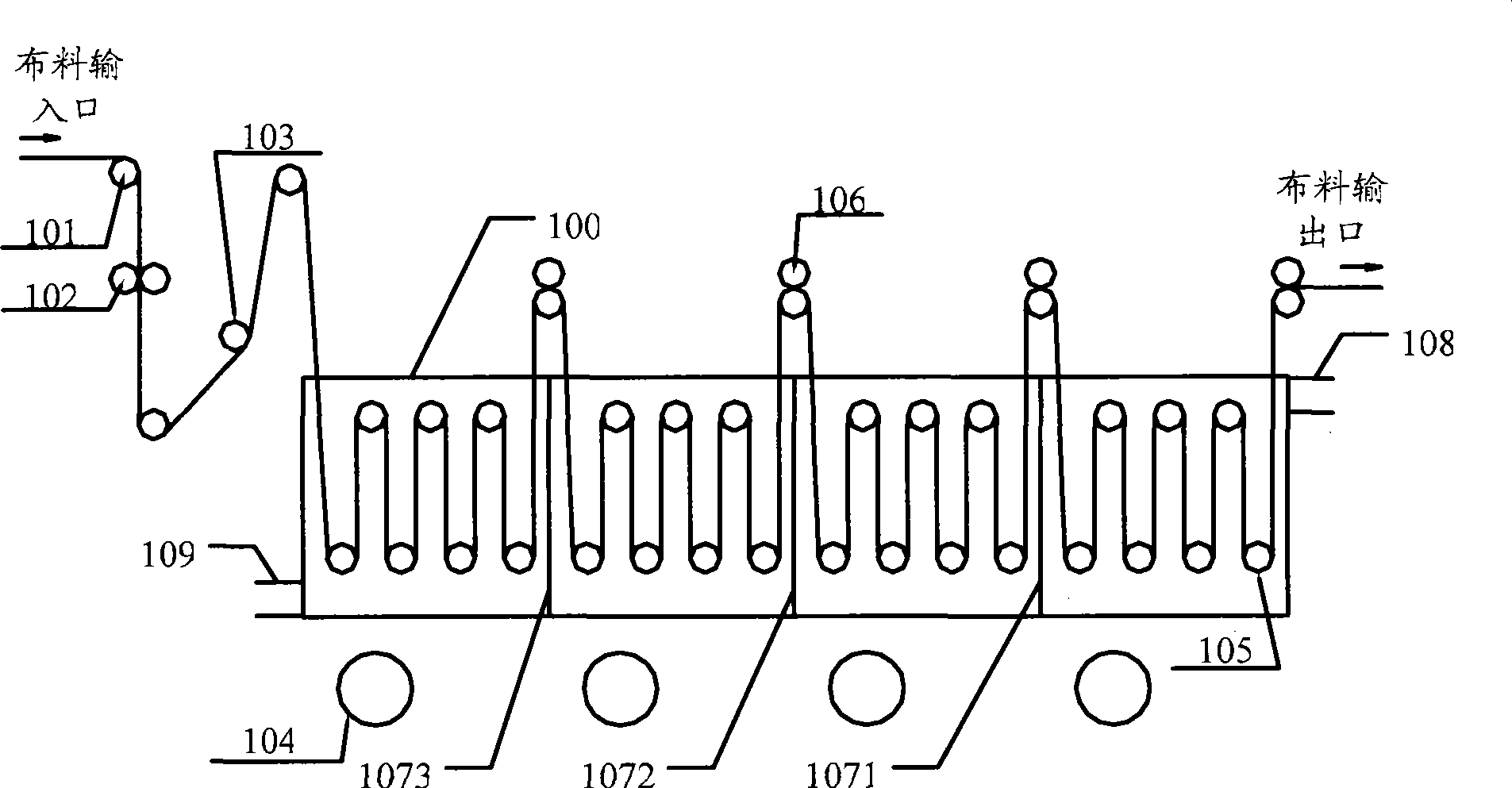

[0014] An embodiment of the present invention provides a cloth cleaning machine, which is used to realize continuous online cleaning of cloth, so as to improve production efficiency.

[0015] The cloth cleaning machine in the embodiment of the present invention may specifically include:

[0016] Cloth input port, guide device, cleaning device and cloth output port;

[0017] The fabric input port is connected with the slag-cloth separating device in the production line, and is used to transport the slag-removed fabric to the guide device;

[0018] The guiding device is used to guide the cloth conveyed by the cloth input port to the cleaning device;

[0019] The cleaning device is used to clean the conveyed cloth, and convey the cleaned cloth to the cloth output port;

[0020] The cloth output port is connected with the filter cloth stacking device in the production line, and is used to transport the cleaned cloth conveyed by the cleaning device to the filter cloth stacking de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com