A kind of surface protection method of flexible printed circuit board

A flexible printing and circuit board technology, applied in the secondary treatment of printed circuits, coating of non-metallic protective layers, etc., can solve the problems of product scrapping, multiple costs, multiple processes, etc., to reduce material waste, save manpower, and reduce processes The effect of the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

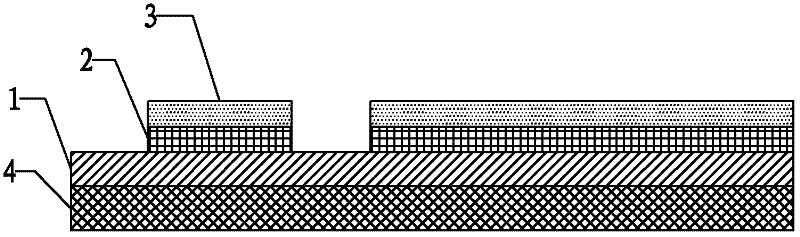

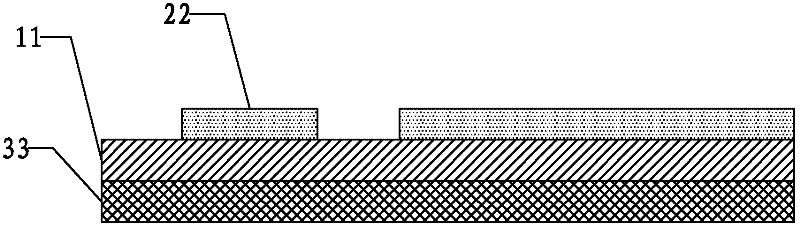

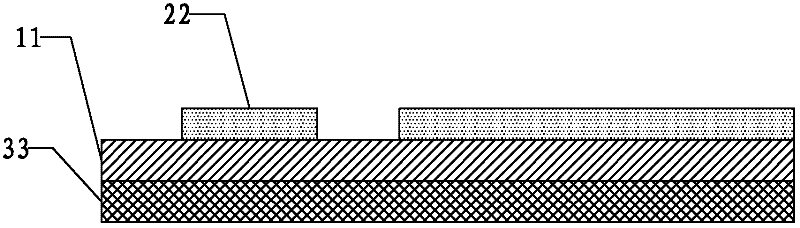

[0020] In order to describe the technical content, structural features, achieved goals and effects of the present invention in detail, the following will be described in detail in conjunction with the embodiments and accompanying drawings.

[0021] The surface protection method of the flexible printed circuit board of the present invention comprises the following steps:

[0022] a. Make screen printing screen;

[0023] b. Alignment adjustment, so that the pattern of the screen printing screen is facing the surface protection area of the flexible printed circuit board;

[0024] c. Evenly print the liquid PI on the surface protection area of the flexible printed circuit board through the pattern of the screen printing screen;

[0025] d. Dry the flexible printed circuit board.

[0026] Said step a is realized in the following manner: adopt 43T polyester (Polyester, or claim Te Duolong) silk screen as screen cloth, make pattern and the surface protection area of circuit b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com