Thermosetting resin composition, cured film, substrate having cured film, electronic component, and ink composition for inkjet

A technology of thermosetting resin and composition, which is applied in the field of thermosetting resin composition, can solve the problems that have not been studied, and achieve the effects of good adhesion, solder resistance and solvent resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

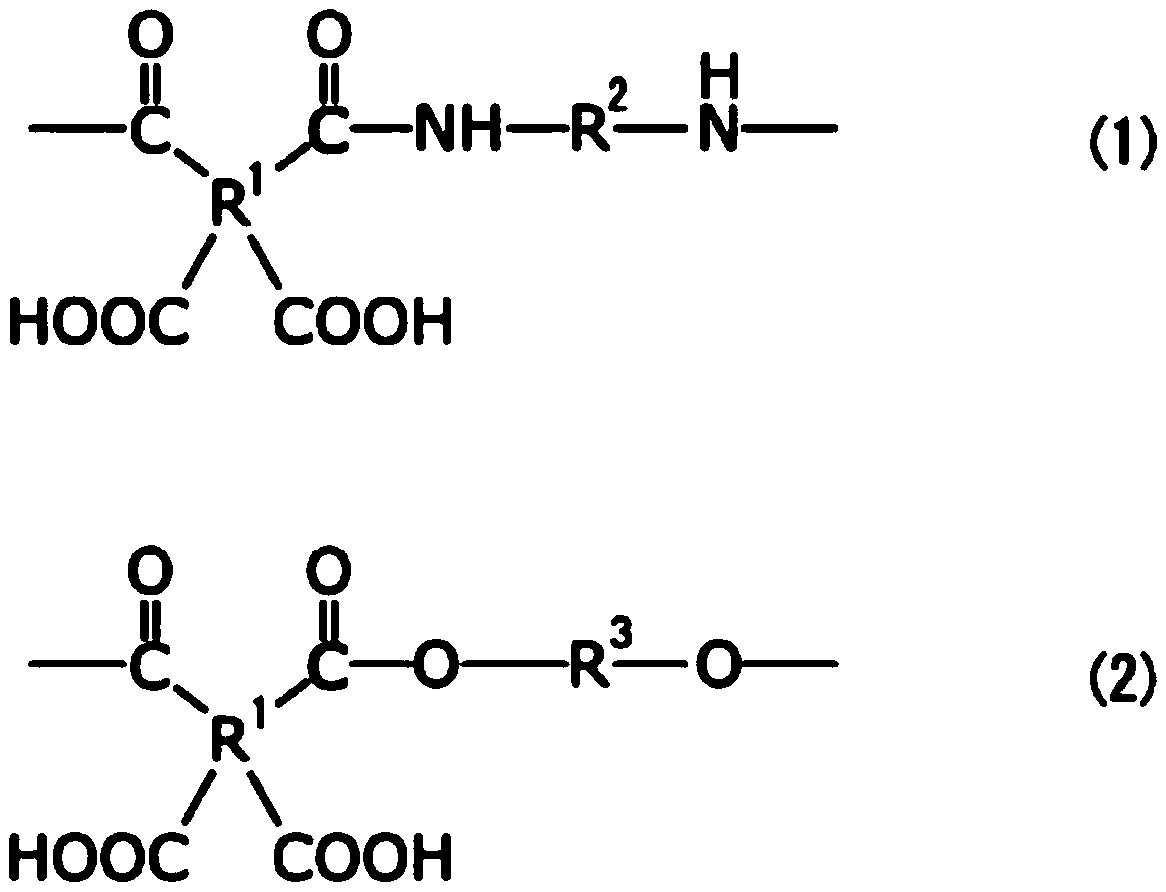

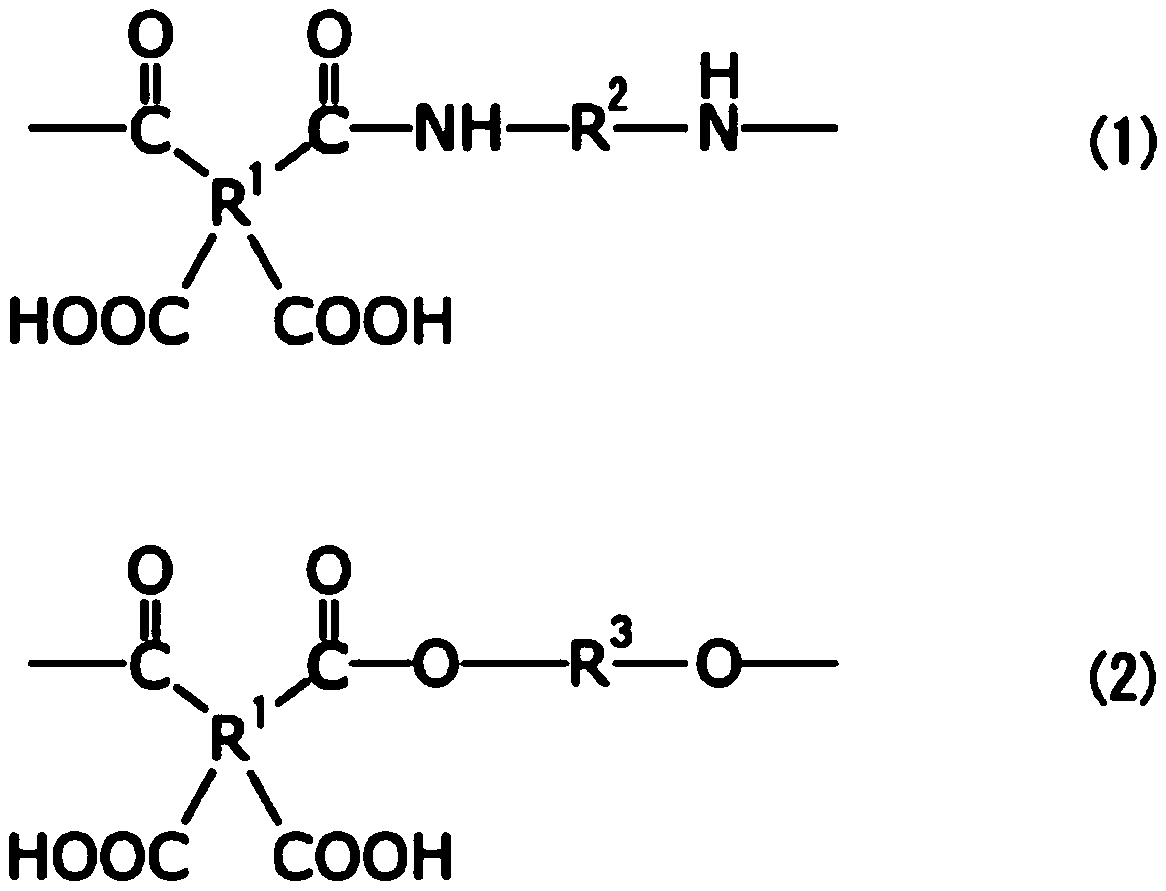

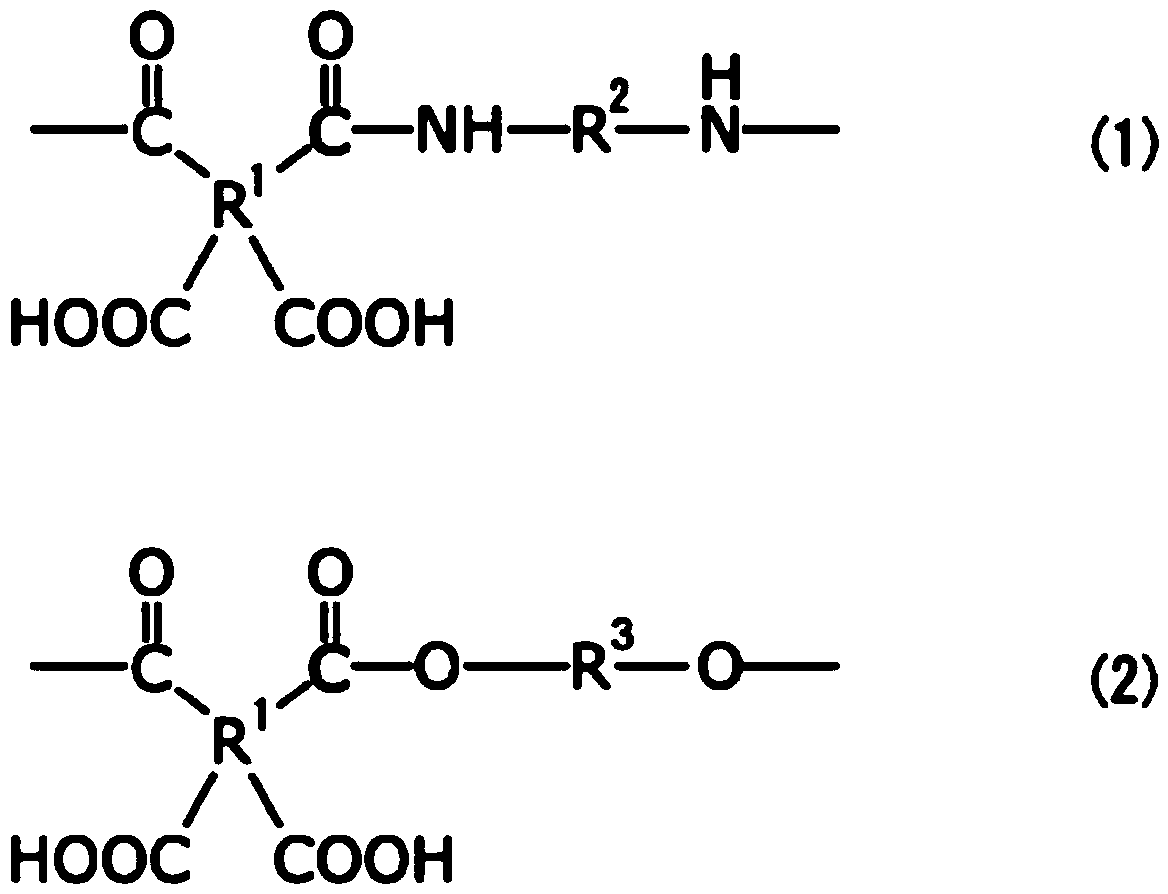

Method used

Image

Examples

preparation example Construction

[0194] 2. Preparation method of thermosetting resin composition

[0195]The composition of the present invention can be prepared by mixing polyester amic acid (A), epoxy compound (B), copolymer (C), solvent (D), colorant (E) and other additives used as needed. preparation. In addition, the composition of the present invention can also directly mix epoxy compound (B), solvent (D), coloring agent ( E) and other additives etc. used as needed are prepared.

[0196] 3. Preservation of the composition

[0197] When the composition of this invention is preserved in the range of -30 degreeC - 25 degreeC, since the temporal stability of a composition will become favorable, it is preferable. If the storage temperature is -25°C to 10°C, no precipitates are present, which is more preferable.

[0198] 4. Manufacturing method of cured film

[0199] The method of manufacturing a cured film using the composition which concerns on one Embodiment of this invention is not limited. Th...

Embodiment

[0225]Hereinafter, although an Example demonstrates this invention, this invention is not limited to these Examples. Synthesis of epoxy compound (B), solvent (D), colorant (E), epoxy hardener (F), surfactant (i), and polyester amic acid (A) used in the examples is shown Tetracarboxylic dianhydride (a1), diamine (a2), polyhydric hydroxy compound (a3), monohydric alcohol (a4), reaction solvent (a5), polybasic anhydride (a6), and copolymer (C) used in the synthesis Names and abbreviations of the monomer (c1), polymerization initiator (c2) and reaction solvent (c3) used. These abbreviations are used in the following description.

[0226]

[0227]

[0228] ODPA: 3,3',4,4'-Diphenyl ether tetracarboxylic dianhydride

[0229]

[0230] DDS: 3,3'-Diaminodiphenylsulfone

[0231]

[0232] BDOH: 1,4-Butanediol

[0233]

[0234] BzOH: benzyl alcohol

[0235]

[0236] MPM: methyl 3-methoxypropionate

[0237] PGMEA: Propylene Glycol Monomethyl Ether Acetate

[0238] EDM: Di...

Synthetic example 1

[0275] Add the MPM of 446.6g and the ODPA of 183.20g, the BDOH of 31.93g, the BzOH of 25.54g as the reaction solvent in the 1000ml separable flask that is equipped with thermometer, stirring blade, raw material input and addition port and nitrogen gas introduction port, in Stirring was carried out at 130° C. for 3 hours under a stream of dry nitrogen. Thereafter, the reaction liquid was cooled to 25° C., 29.33 g of DDS and 183.4 g of MPM were thrown in, and stirred at 20° C. to 30° C. for 2 hours, then at 115° C. for 1 hour. Then, by cooling to 30 degreeC or less, the 30 weight% solution of the pale yellow transparent polyester amic acid was obtained.

[0276] The rotational viscosity of the solution was 29 mPa·s. Here, the rotational viscosity is a value measured at 25°C using an E-type viscometer (trade name: VISCONIC END, manufactured by Tokyo Keiki Co., Ltd.) (the same applies hereinafter).

[0277] The weight average molecular weight of the obtained polyester amic acid ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com