Support structure for hidden frame glass curtain wall

A technology of hidden frame glass curtain wall and supporting structure, which is applied in the direction of walls, building components, building structures, etc., which can solve the problems of not being suitable for high-strength use, short service life, and easy deformation, etc., and achieve beautiful appearance and corrosion resistance Strong and protective effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] In order to deepen the understanding of the present invention, the present invention will be further described below in conjunction with examples, which are only used to explain the present invention and do not constitute a limitation to the protection scope of the present invention.

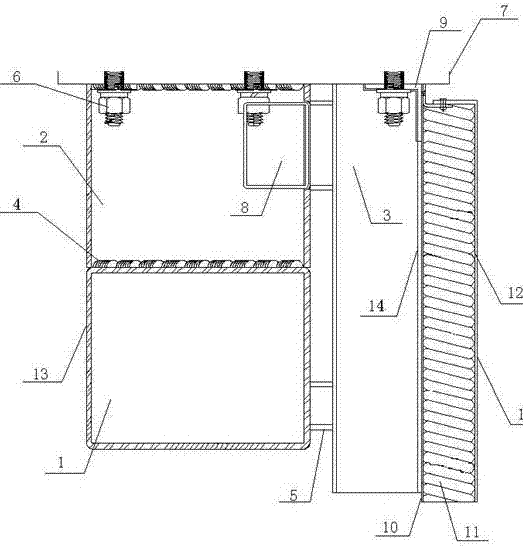

[0012] This example figure 1 As shown: the supporting structure of the hidden frame glass curtain wall adopts the first steel square tube 1, the second steel square tube 2 and the third party steel tube 3, and the fourth steel square tube 8 is arranged on the second steel square tube 2 The four-steel square tube support structure strengthens the firmness of the internal structure of the hidden frame glass curtain wall, and the ends of the second steel square tube 2 and the third-party steel tube 3 are respectively fixed on the galvanized steel buried plate 7 by chemical bolts 6 In addition, the chemical bolt 6 has excellent corrosion resistance, and can adapt to low temperature and high t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com