Preparation method of zinc alloy pipe for degradable cardiovascular stent

A zinc alloy and cardiovascular technology, applied in the field of zinc alloy pipe preparation, can solve the problems of long preparation process and complicated process, and achieve the effects of simplifying the processing technology, improving the processing efficiency and reducing the number of annealing times.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] The composition of the zinc-magnesium-manganese alloy contains 0.05% of Mg, 0.5% of Mn, unavoidable impurities ≤ 10ppm, and the balance of Zn.

[0036] (1) Prepare metal zinc, metal magnesium, and metal manganese as raw materials for smelting according to the stated ingredients. First, heat the metal zinc to 550±5°C. After it melts, add magnesium and manganese in turn. After it is completely melted, stir uniform. Lower the molten metal to 480±10°C, cast it into a water-cooled iron mold to cool down, and obtain a hollow ingot;

[0037] (2) Homogenization treatment: the ingot is kept at 380°C for 12 hours, and then cooled to room temperature in water;

[0038] (3) Hot extrusion deformation: heat the hollow ingot billet at 150°C for 30 minutes, and then carry out hot extrusion forming at 100°C, with an extrusion speed of 0.5mm / s;

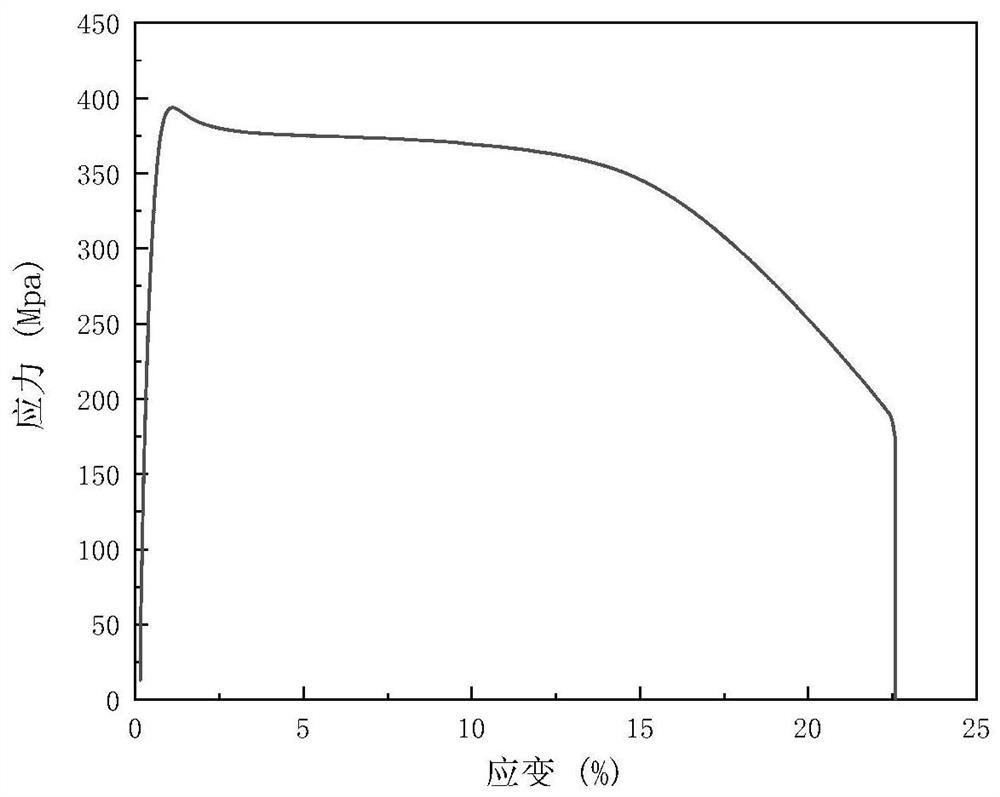

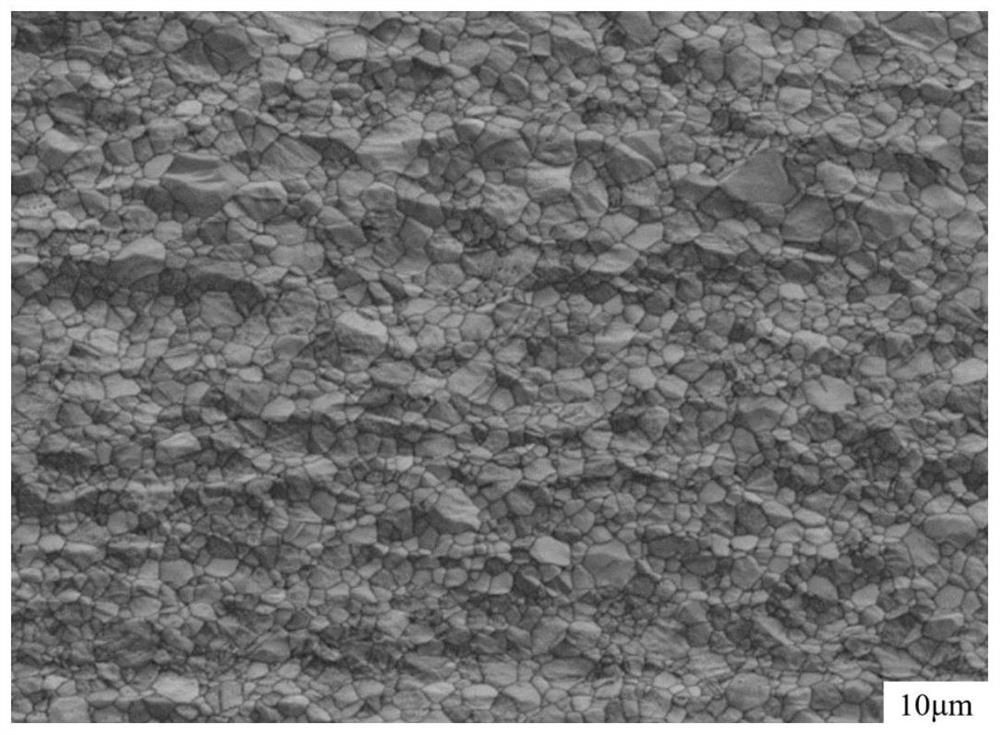

[0039] (4) Hot drawing deformation: the accumulated deformation of hot drawing is 75-80%. The hot drawing process parameters are as follows:...

Embodiment 2

[0049] The composition of the zinc-magnesium-copper alloy contains 0.05% of Mg, 0.5% of Cu, unavoidable impurities ≤ 10ppm, and the balance of Zn.

[0050] (1) Prepare metal zinc, metal magnesium, and metal copper as raw materials for smelting according to the stated ingredients. First, heat the metal zinc to 550±5°C. After it melts, add magnesium and copper elements in turn. After they are all melted, stir uniform. Lower the molten metal to 480±10°C, cast it into a water-cooled iron mold to cool down, and obtain a hollow ingot;

[0051] (2) Homogenization treatment: the ingot is kept at 380°C for 15 hours, and then cooled to room temperature in water;

[0052] (3) Hot extrusion deformation: heat the hollow ingot billet at 150°C for 30 minutes, and then carry out hot extrusion forming at 100°C, with an extrusion speed of 1mm / s;

[0053] (4) Hot drawing deformation: the accumulated deformation of hot drawing is 85-95%. The hot drawing process parameters are as follows: the d...

Embodiment 3

[0057] The composition of the zinc-magnesium-phosphorus alloy contains Mg 0.05%, P 0.02%, unavoidable impurities ≤ 10ppm, and Zn as the balance.

[0058] (1) Prepare metal zinc, metal magnesium, and phosphorus as raw materials for smelting according to the stated ingredients. First, heat the metal zinc to 550±5°C. After it melts, add magnesium and phosphorus elements in turn. After it is completely melted, stir evenly . Lower the molten metal to 480±10°C, cast it into a water-cooled iron mold to cool down, and obtain a hollow ingot;

[0059] (2) Homogenization treatment: the ingot is kept at 380°C for 20 hours, and then cooled to room temperature in water;

[0060] (3) Hot extrusion deformation: heat the hollow ingot billet at 150°C for 30 minutes, and then carry out hot extrusion at 100°C, with an extrusion speed of 0.2mm / s;

[0061] (4) Hot drawing deformation: the accumulated deformation of hot drawing is 80-85%. The hot drawing process parameters are as follows: the dra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com