Magnesium alloy as well as preparation method and application thereof

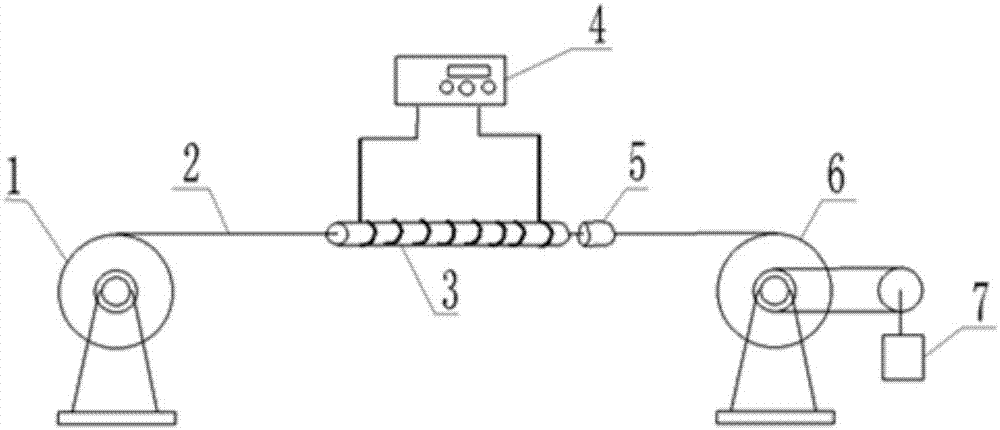

The technology of magnesium alloy and wire drawing die is applied in the field of wear-resistant magnesium alloy, which can solve the problems of complex equipment and high production cost, and achieve the effects of reducing energy consumption and cost, low cost and high drawing speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

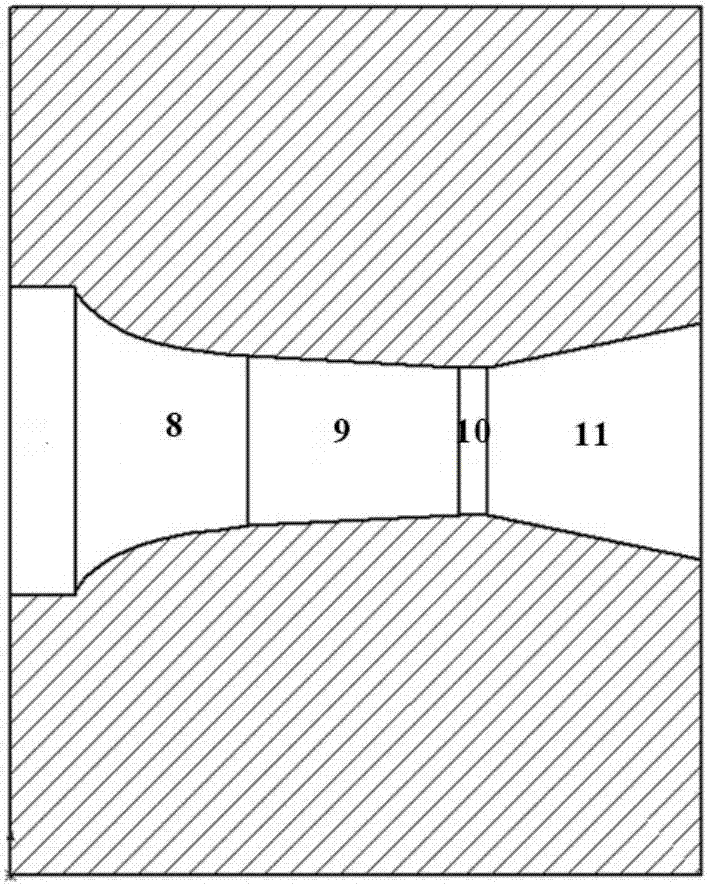

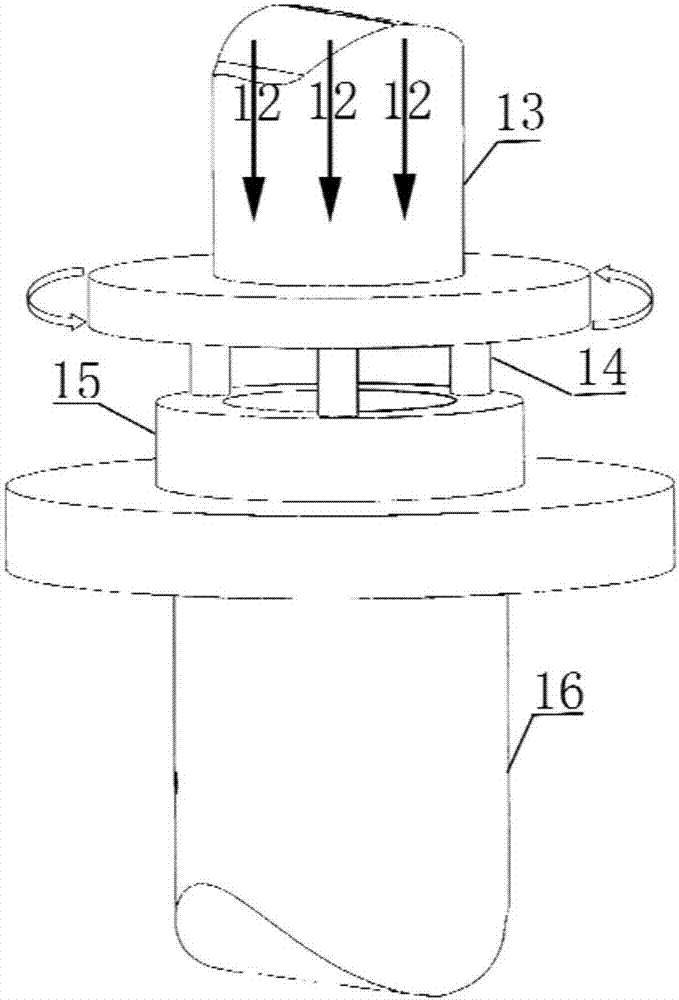

Method used

Image

Examples

Embodiment 1

[0075] Using a resistance furnace for smelting, under the protection of No. 5 flux, melt the magnesium metal and heat it to 745°C, then add 9.80% pure aluminum ingot, 0.20% pure zinc ingot, 0.73% manganese agent, 5.33 % Mg-30Gd master alloy and 7.10% Mg-30Y master alloy. Purify the obtained magnesium alloy melt with No. 5 flux at 730°C, and cool down to 680°C after stirring, standing still, and removing slag. in volume ratio to CO 2 :SF 6 Under the protection of the mixed gas of =10:1, carry out semi-continuous casting, obtain the magnesium alloy ingot that diameter is 152mm, length is 360mm, and casting speed is 90mm / min, and cooling water is 60L / min. Homogenizing annealing was performed on the ingot at a temperature of 410° C. for 24 hours. The homogenized annealed ingot was turned to obtain a cylindrical ingot with a diameter of 140 mm and a height of 340 mm. The FOUNDRY-MASTER PRO direct-reading spark spectrometer was used to detect the composition of the ingot, and th...

Embodiment 2

[0080] Using a resistance furnace for smelting, under the protection of No. 5 flux, melt and heat the metal magnesium to 735°C, and then add 8.40% pure aluminum ingot, 1.55% pure zinc ingot, 0.90% manganese agent, 6.05% % Mg-30Gd master alloy and 3.98% Mg-30Y master alloy. Purify the obtained magnesium alloy melt with No. 5 flux at 730°C, and cool down to 700°C after stirring, standing still, and removing slag. in volume ratio to CO 2 :SF 6 Under the protection of the mixed gas of =10:1, carry out semi-continuous casting, obtain the magnesium alloy ingot that diameter is 152mm, length is 370mm, and casting speed is 90mm / min, and cooling water is 60L / min. Homogenizing annealing was performed on the ingot at a temperature of 410° C. for 12 hours. The homogenized annealed ingot was turned to obtain a cylindrical ingot with a diameter of 140 mm and a height of 340 mm. The FOUNDRY-MASTER PRO direct-reading spark spectrometer was used to detect the composition of the ingot, and ...

Embodiment 3

[0085] Using a resistance furnace for smelting, under the protection of No. 5 flux, melt the magnesium metal and heat it to 741°C, then add 9.72% pure aluminum ingot, 1.32% pure zinc ingot, 0.52% manganese agent, 3.80% by mass percentage % Mg-30Gd master alloy and 1.90% Mg-30Y master alloy. Purify the obtained magnesium alloy melt with No. 5 flux at 730°C, and cool down to 690°C after stirring, standing still, and removing slag. in volume ratio to CO 2 :SF 6 Under the protection of the mixed gas of =10:1, carry out semi-continuous casting, obtain the magnesium alloy ingot that diameter is 152mm, and length is 358mm, and casting speed is 90mm / min, and cooling water is 60L / min. Homogenizing annealing was performed on the ingot at a temperature of 410°C for 20 hours. The homogenized annealed ingot was turned to obtain a cylindrical ingot with a diameter of 140 mm and a height of 340 mm. The FOUNDRY-MASTER PRO direct-reading spark spectrometer was used to detect the compositio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com