Mg-Al-Zn-Gd-Ce alloy and preparing method and application thereof

A cerium alloy, magnesium-aluminum-zinc technology, applied in the field of wear-resistant magnesium-aluminum-zinc-gadolinium-cerium alloy, can solve the problems of high production cost, complex equipment, etc., and achieve the effects of low cost, reduced energy consumption and cost, and increased service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

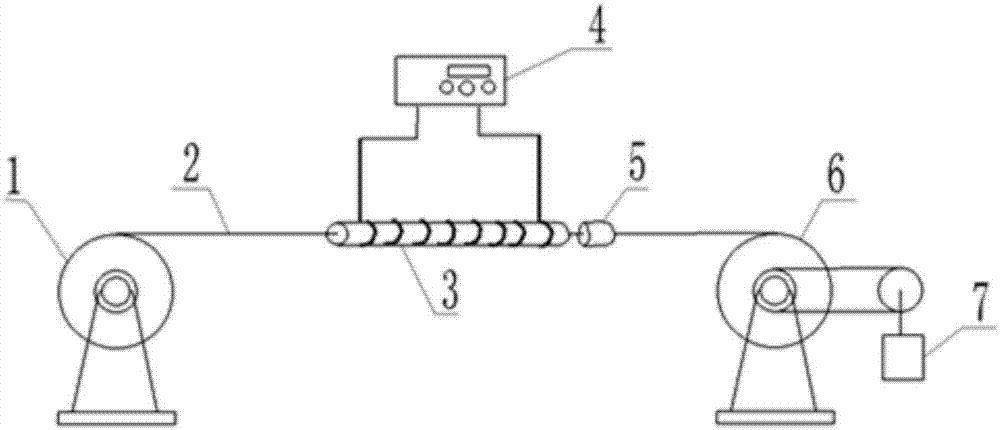

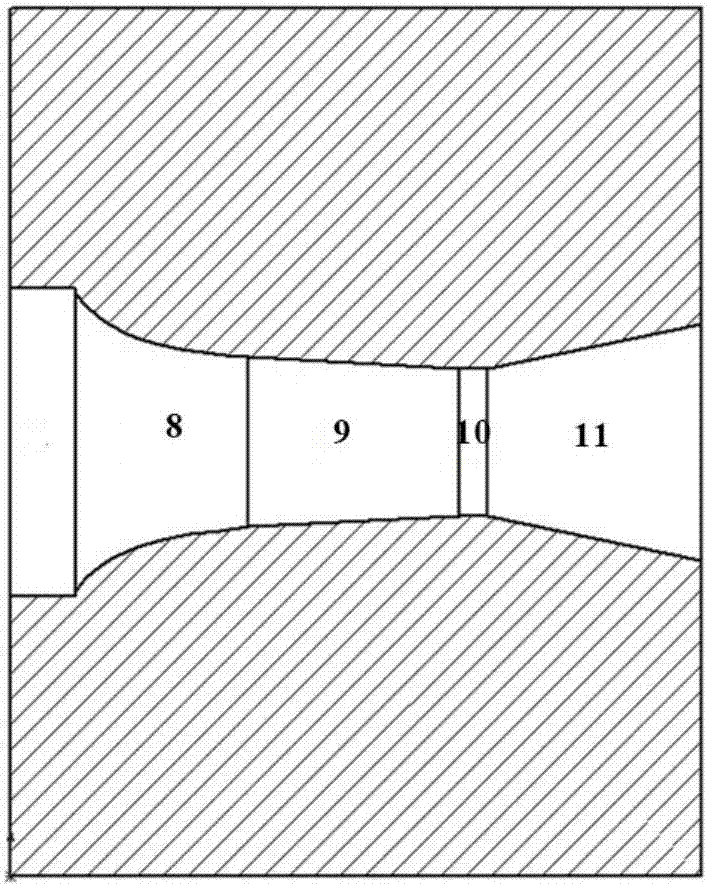

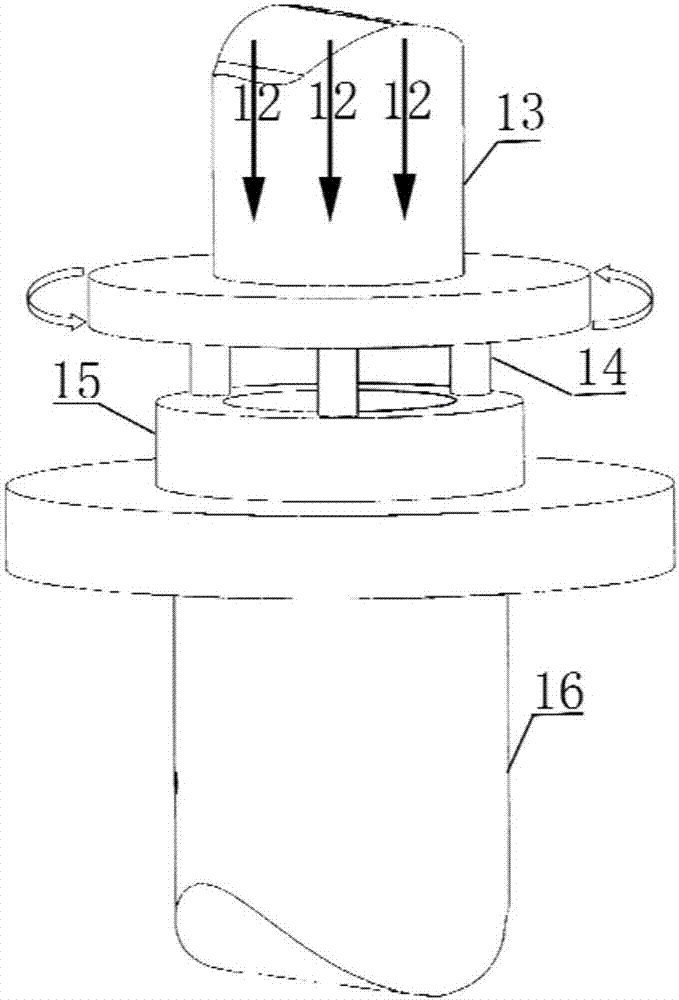

[0075] Using a resistance furnace for smelting, under the protection of No. 5 flux, melt the magnesium metal and heat it to 740°C, then add 3.38% pure aluminum ingot, 1.26% pure zinc ingot, 0.50% manganese agent, 5.86 % Mg-30Gd master alloy and 8.43% Mg-30Ce master alloy. Purify the obtained magnesium-aluminum-zinc-gadolinium-cerium alloy melt at 730°C with No. 5 flux, and cool it down to 695°C after stirring, standing still, and removing slag. in volume ratio to CO 2 :SF 6 Under the protection of the mixed gas of =10:1, semi-continuous casting is carried out, and diameter is 152mm, and length is the ingot of magnesium-aluminum-zinc-gadolinium-cerium alloy of 363mm, and casting speed is 90mm / min, and cooling water is 60L / min. Homogenizing annealing was performed on the ingot at a temperature of 410° C. for 12 hours. The homogenized annealed ingot was turned to obtain a cylindrical ingot with a diameter of 140 mm and a height of 340 mm. The FOUNDRY-MASTER PRO direct-reading...

Embodiment 2

[0080] Using a resistance furnace for smelting, under the protection of No. 5 flux, melt the magnesium metal and heat it to 752°C, then add 2.60% pure aluminum ingot, 0.30% pure zinc ingot, 0.43% manganese agent, 9.10% by mass percentage % Mg-30Gd master alloy and 12.00% Mg-30Ce master alloy. Purify the obtained magnesium-aluminum-zinc-gadolinium-cerium alloy melt at 730°C with No. 5 flux, and cool it down to 707°C after stirring, standing still and removing slag. in volume ratio to CO 2 :SF 6 Under the protection of the mixed gas of =10:1, semi-continuous casting is carried out, and diameter is 152mm, and length is the ingot of magnesium-aluminum-zinc-gadolinium-cerium alloy of 380mm, casting speed is 90mm / min, and cooling water is 60L / min. The ingot was subjected to homogenization annealing at a temperature of 410° C. for 15 hours. The homogenized annealed ingot was turned to obtain a cylindrical ingot with a diameter of 140 mm and a height of 340 mm. The FOUNDRY-MASTER ...

Embodiment 3

[0085] Using resistance furnace for smelting, under the protection of No. 5 flux, metal magnesium is melted and heated to 760°C, and then 2.83% pure aluminum ingot, 0.64% pure zinc ingot, 0.61% manganese agent, 10.76 % Mg-30Gd master alloy and 9.19% Mg-30Ce master alloy. Purify the obtained magnesium-aluminum-zinc-gadolinium-cerium alloy melt at 730°C with No. 5 flux, and cool it down to 680°C after stirring, standing still, and removing slag. in volume ratio to CO 2 :SF 6 Under the protection of the mixed gas of =10:1, carry out semi-continuous casting, obtain the ingot of magnesium-aluminum-zinc-gadolinium-cerium alloy that diameter is 152mm, and length is 370mm, and casting speed is 90mm / min, and cooling water is 60L / min. Homogenizing annealing was performed on the ingot at a temperature of 410°C for 21 hours. The homogenized annealed ingot was turned to obtain a cylindrical ingot with a diameter of 140 mm and a height of 340 mm. The FOUNDRY-MASTER PRO direct-reading sp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com