Hydraulic hose performance test experiment table

A technology for testing experiments and hydraulic hoses, which is applied in the direction of applying stable tension/pressure to test the strength of materials, measuring devices, instruments, etc. Reflect objective reality, large energy consumption and other issues, achieve good energy saving effect, wide practicability, and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] An embodiment of the present invention will be further described below in conjunction with accompanying drawing:

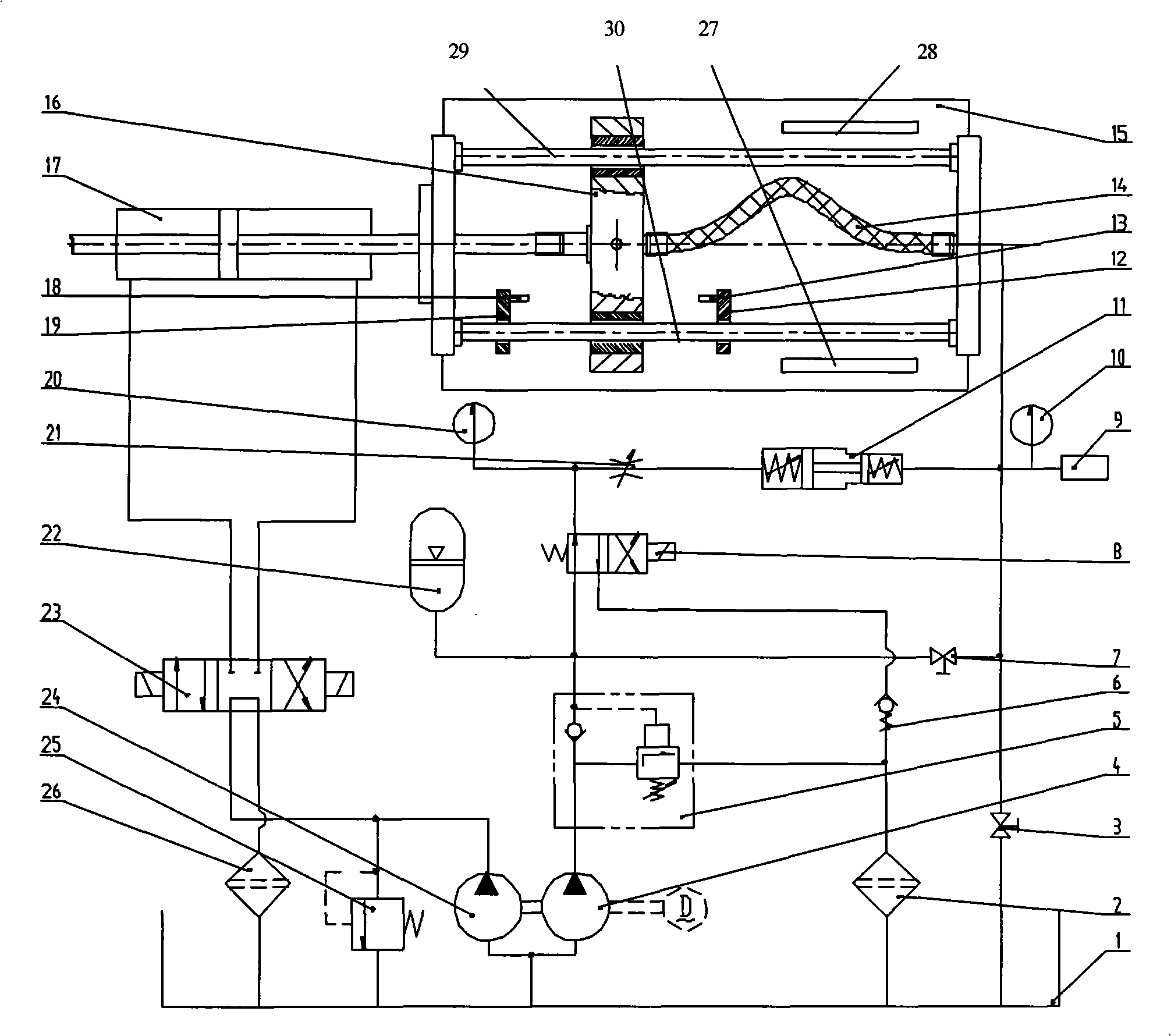

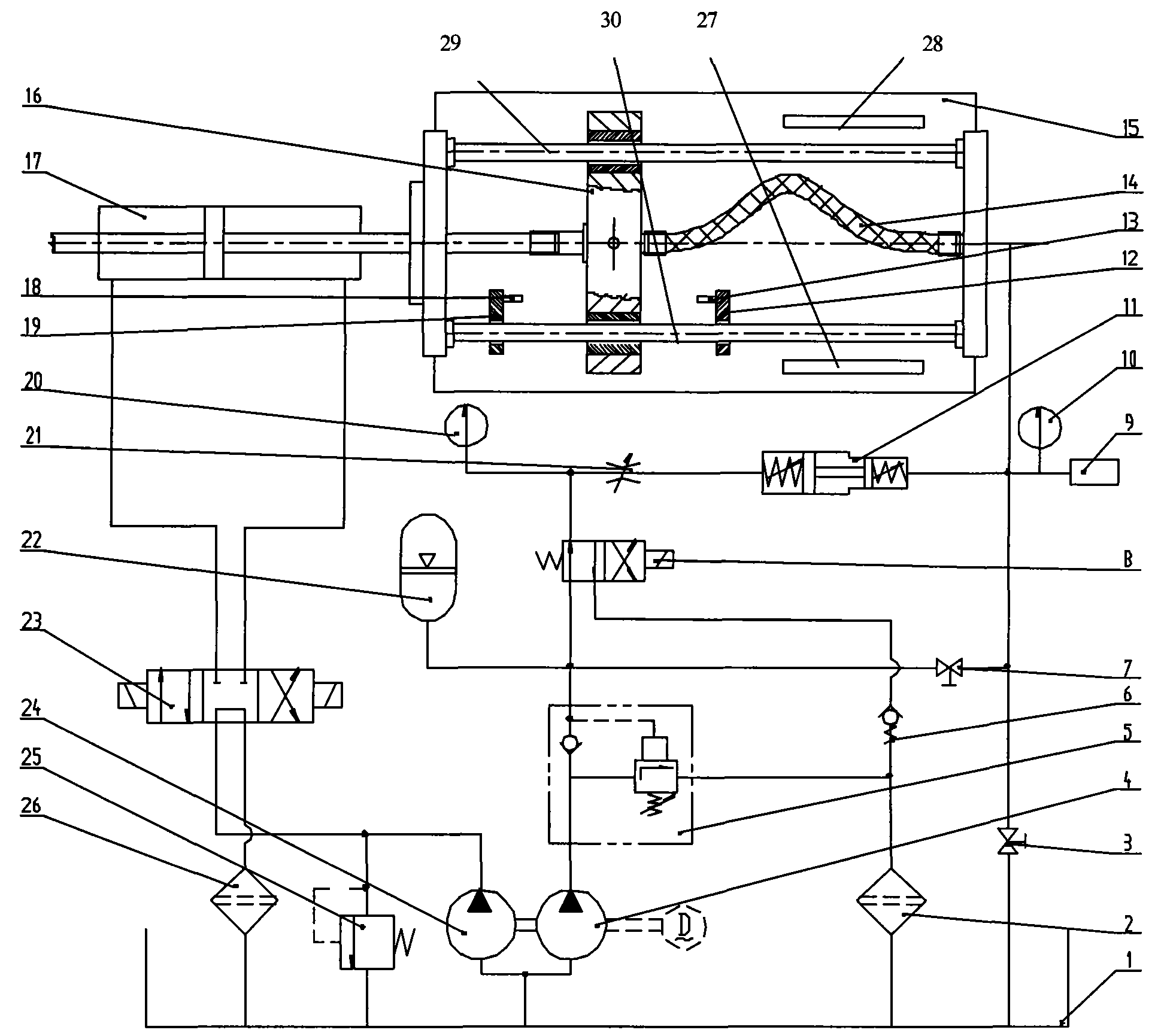

[0012] As shown in the drawings, the hydraulic hose performance test bench of the present invention is mainly composed of an electric control system, an impact loading system, a bending driving system of the tested hose and an environmental simulator connected to each other.

[0013] The impact loading system is mainly composed of hydraulic oil pump I4, unloading overflow valve 5, accumulator 22, two-position four-way solenoid valve 8, throttle valve 21, supercharger 11, stop valve 3, 7, back pressure valve 6, Oil return filter I2, pressure gauge, pressure sensor 9, oil tank 1, connecting oil pipes, joints and so on. The oil suction port of the hydraulic oil pump I4 is connected to the oil tank 1 through the oil pipe, and an unloading overflow valve 5 is installed at the oil outlet, and the overflow port of the unloading overflow valve 5 is connected to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com