Micro clamp device with adjustable and controllable internal stress

A fixture device, internal stress technology, applied in the direction of discharge tubes, electrical components, circuits, etc., can solve problems such as lack of bending of test samples

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

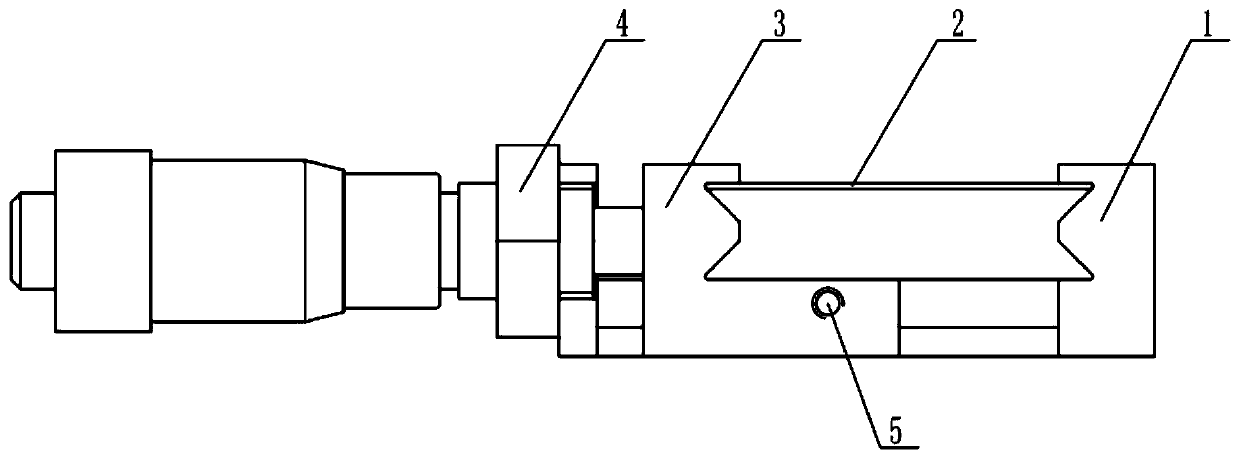

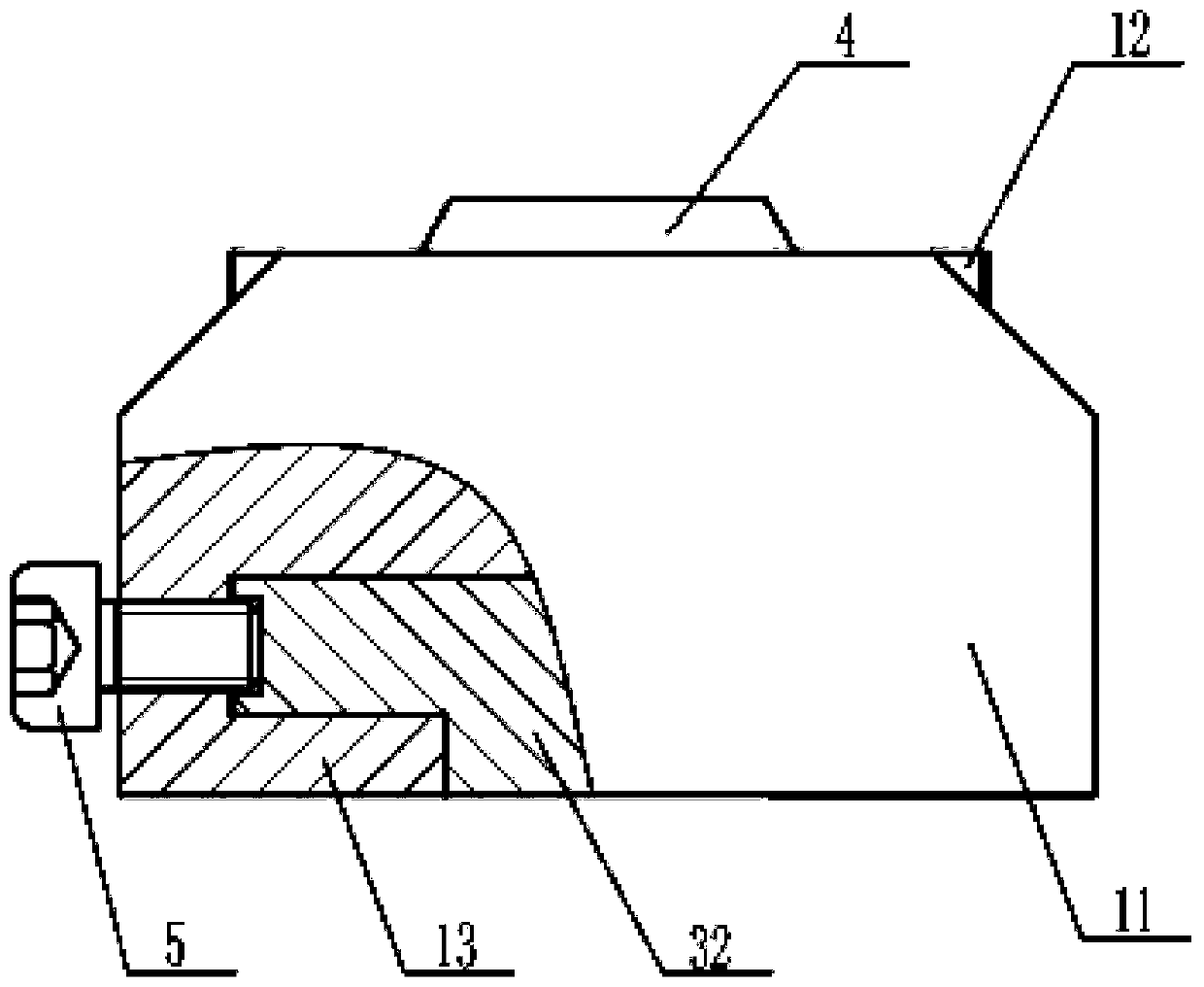

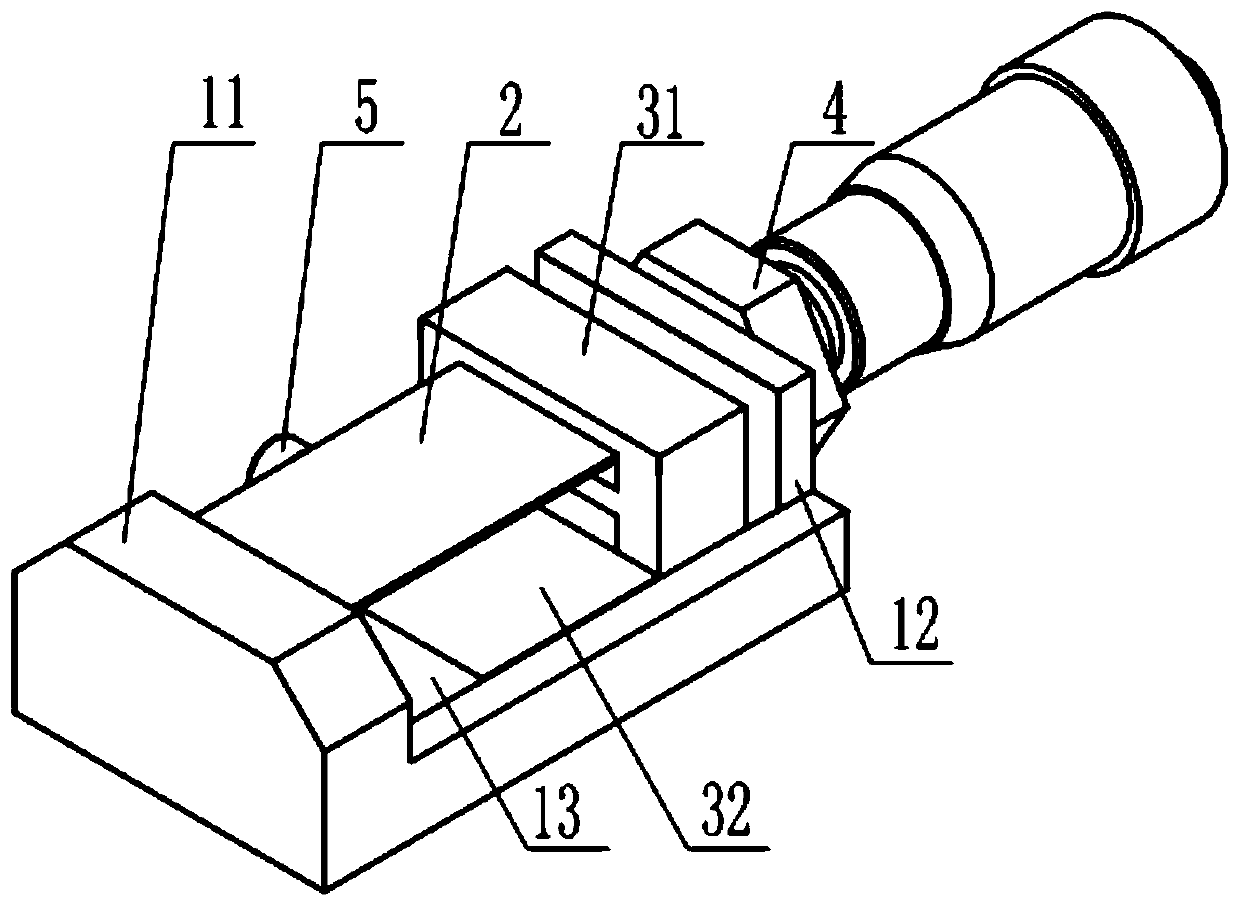

[0031] In one embodiment of the present invention, as Figure 1-5 As shown, a micro-clamp device with adjustable internal stress is provided, including a clamp seat 1, a sliding block 3 and a screw micrometer head 4, and the sliding block 3 and the screw micrometer head 4 are all movably arranged on the clamp seat 1, and the clamp seat 1. Both sides of the baffle plate 11 and baffle plate 2 12 are provided with a trapezoidal chute 13 on the clamp seat 1 between the baffle plate 11 and the baffle plate 2 12. One side of the trapezoidal chute 13 is provided with a pin 5 matching There are two reversed triangular grooves in mirror image distribution on the baffle plate 11, and the tip of the triangular grooves is rounded. A threaded hole matching the spiral micrometer 4 is arranged on the baffle plate 2 12. The micrometer head 4 can drive th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com