Improved straightening machine

A straightening machine, a pair of technology, applied in the direction of safety equipment, manufacturing tools, metal processing equipment, etc., can solve the problems of unreachable pressure, high oil temperature, and reduced work efficiency, so as to reduce high oil temperature and ensure working pressure , the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

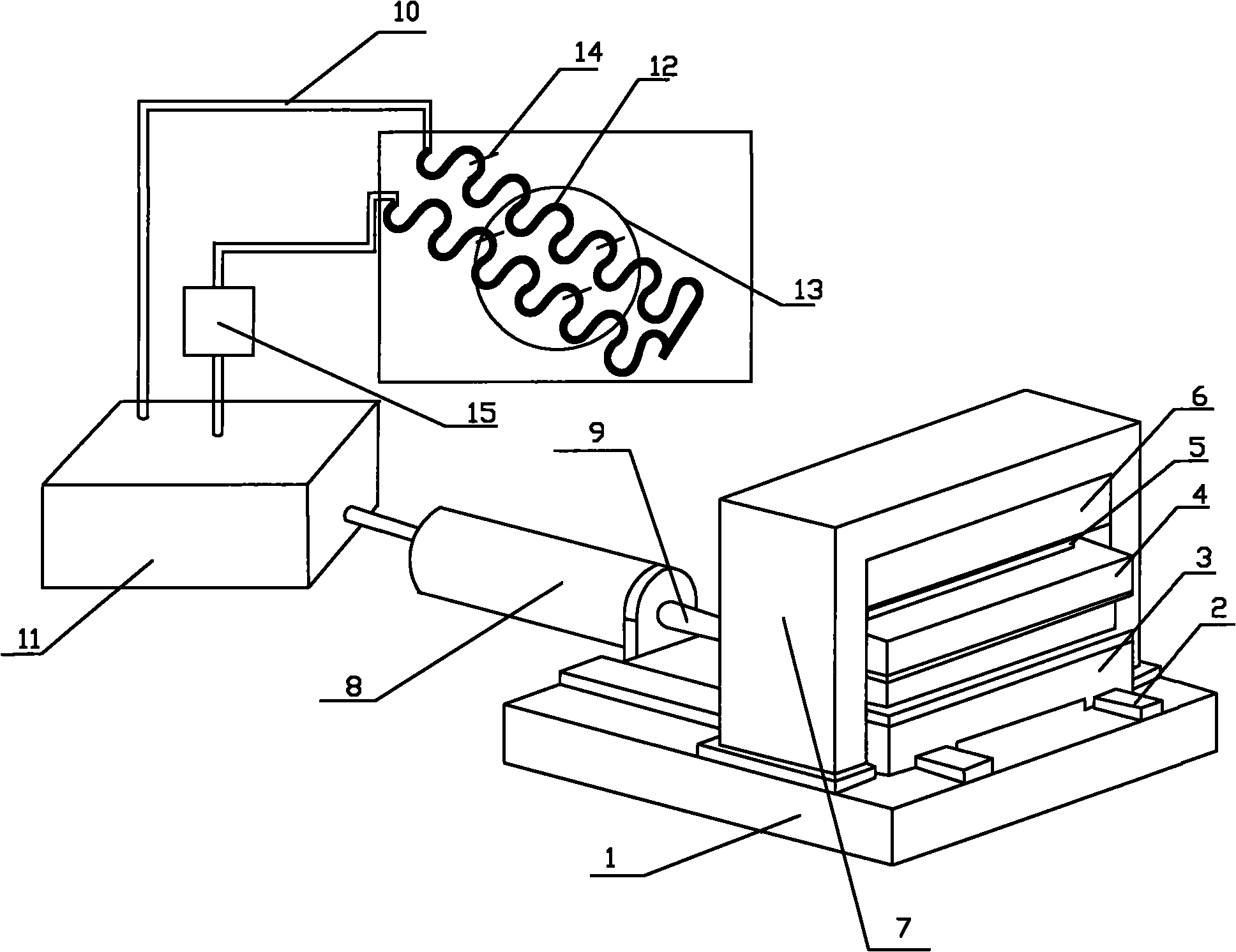

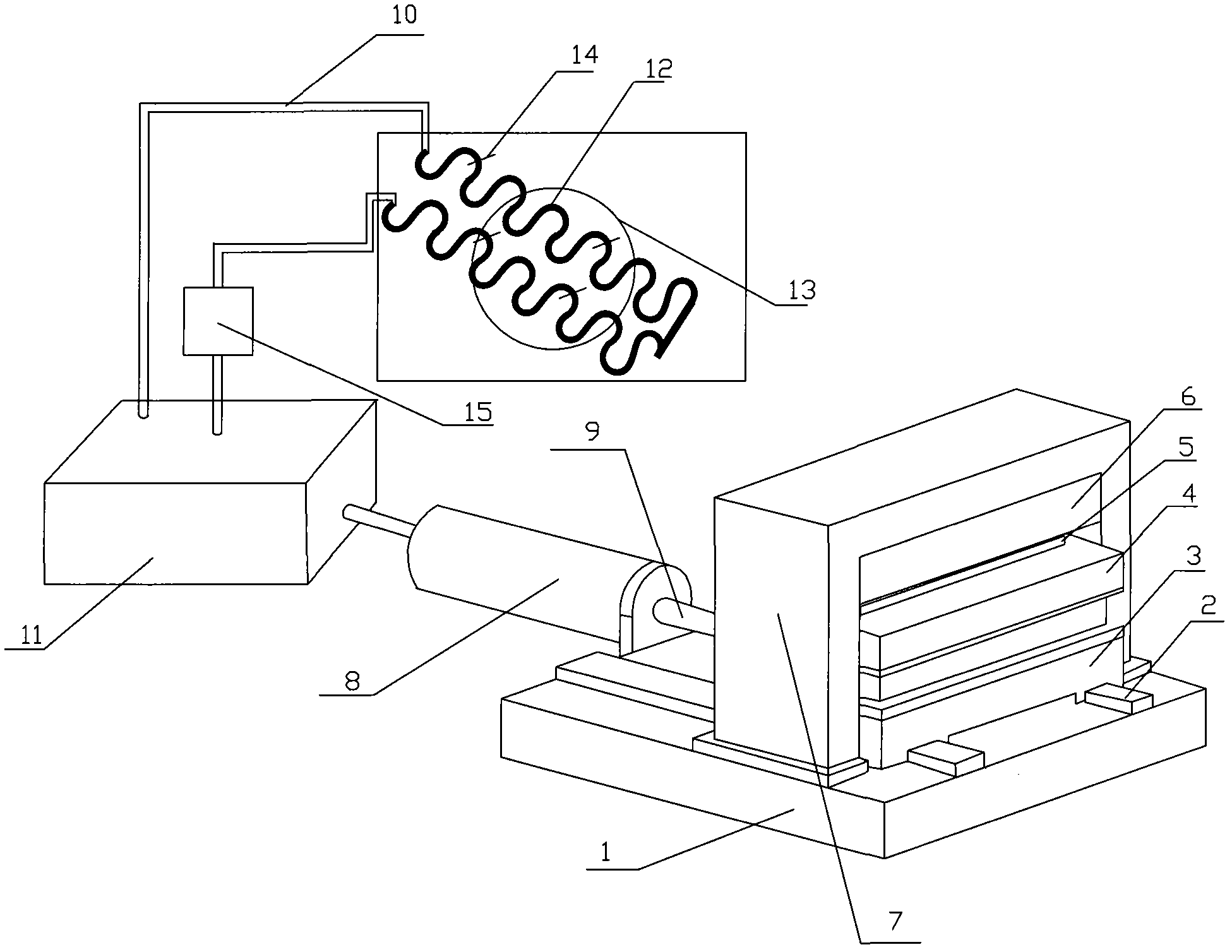

[0011] Such as figure 1 As shown, an improved straightening machine of the present invention includes a base 1, a slide table 3, a lower template 4, an upper template 6 and a hydraulic cylinder 8, and a pair of guide rails 2 are arranged on the base 1, and slide rails are embedded between the guide rails 2. The upper part of the table 3 and the sliding table 3 is equipped with a lower formwork 4, and the lower formwork 4 is provided with a camshaft 5 in contact with the upper formwork 6. The upper formwork 6 is fixed on the beam of the gantry 7, and the gantry 7 is fixed on the base 1. The platform 3 is connected with the hydraulic cylinder 8 through the central shaft 9 fixed at one end of the base 1, the hydraulic cylinder 8 is connected with the fuel tank 11 through the pipeline 10, the outlet of the fuel tank 11 is connected with the inlet of the oil circuit 15, the oil return port of the oil circuit 15 is connected with the drop The inlet of the oil temperature device is c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com