System for adjusting hydrogen-carbon ratio of synthesis gas and simultaneously producing byproduct hydrogen through coupling of membrane separation and pressure swing adsorption

A technology of pressure swing adsorption and coupling adjustment, which is applied in hydrogen/synthesis gas production, hydrogen separation, diffusion hydrogen separation, etc., to achieve the effects of reducing operating costs, reducing power consumption, and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

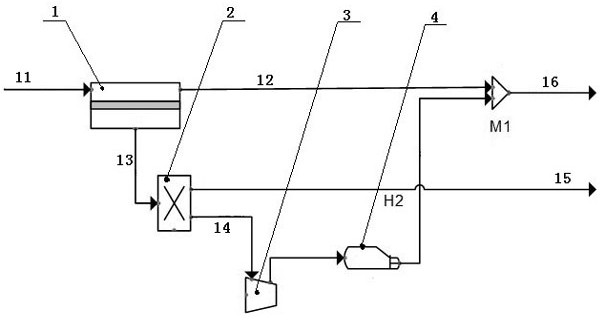

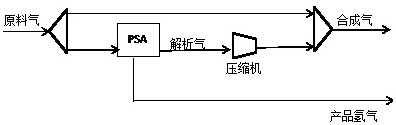

Method used

Image

Examples

Embodiment 1

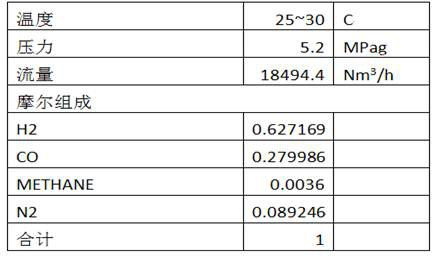

[0035] Crude feed gas conditions:

[0036]

[0037] Gas separation requirements:

[0038] Product gas 1: hydrogen for export: flow rate is about 6350Nm 3 / h, purity H2>99.9%, pressure ≥2.4MPaG.

[0039] Product gas 2: Gases other than hydrogen are mixed into "carbonylation synthesis gas", which is used as the raw material for the downstream carbonylation unit. The ratio of H2:CO in this "carbonylation synthesis gas" is required to be about 1:1 (molar ratio). Pressure ≥ 2.3MPaG.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com