Method and device for desalting water

A desalination, brine technology, applied in chemical instruments and methods, seawater treatment, water/sewage treatment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

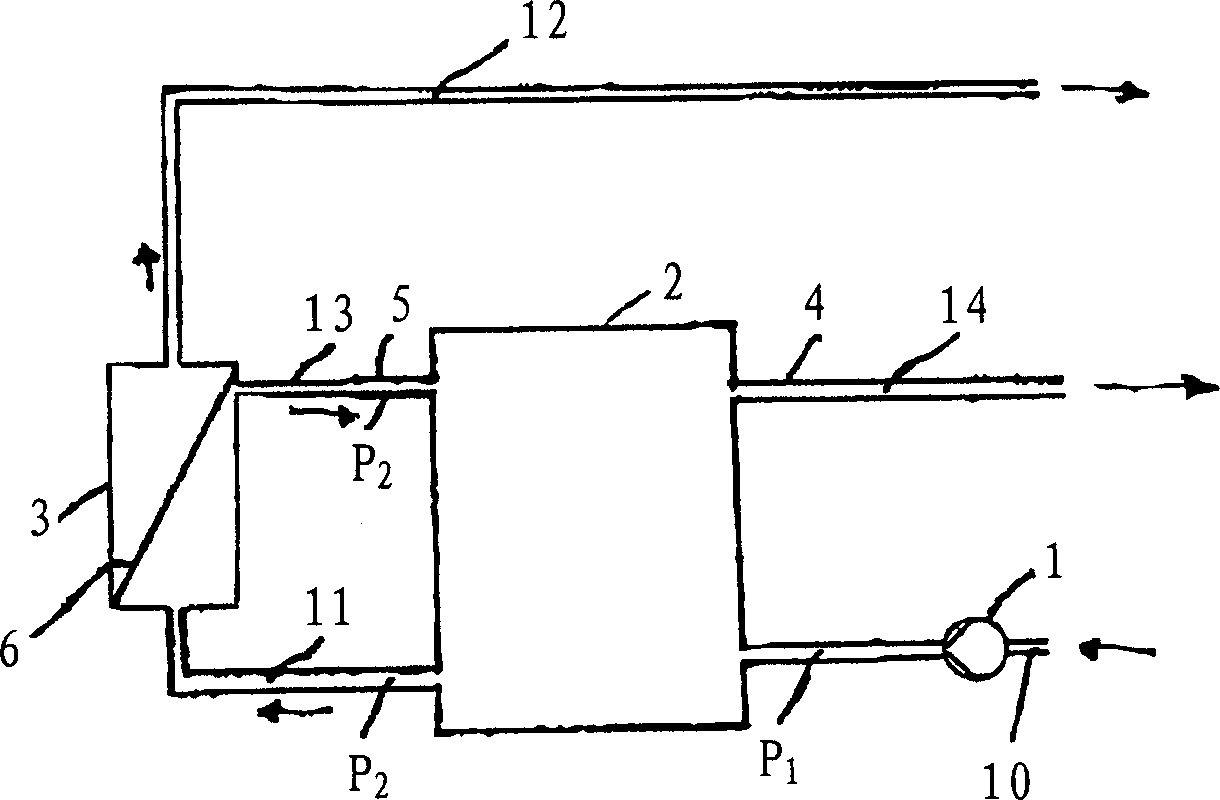

[0024] figure 1 The schematic representation of the first pressure P 1 Next, brine 10 is fed to a feed pump 1 in the pressure compensation device 2 . The same brine 11 at high working pressure is sent from the pressure compensation device 2 to the diaphragm assembly 3 . A portion of the brine 11 (eg 25% brine 11 ) that passes through the membrane 6 is desalinated in the process and is discharged as desalinated water 12 . The remaining brine 11 (for example, 75%) cannot pass through the diaphragm 6 and uses the connecting line 5 as the still almost high pressure P 2 The concentrated brine 13 is returned to the pressure compensation device 2. This high pressure is added to the brine 10 fed into the pressure compensating device 2 and sent to the input of the diaphragm assembly 3 in a manner to be described. Simultaneously, this pressure is utilized in the manner to be explained in the pressure compensating device 2 , and finally the concentrated brine 14 there is discharged t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com