Groove clamping hoop type pipeline joint

A pipe joint and clamp type technology, applied in the field of pipe joints, can solve the problems of uneconomical, slow flange connection, hidden danger of pollution, etc., and achieve the effect of cutting off the transmission of noise and vibration, fast installation and cost saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

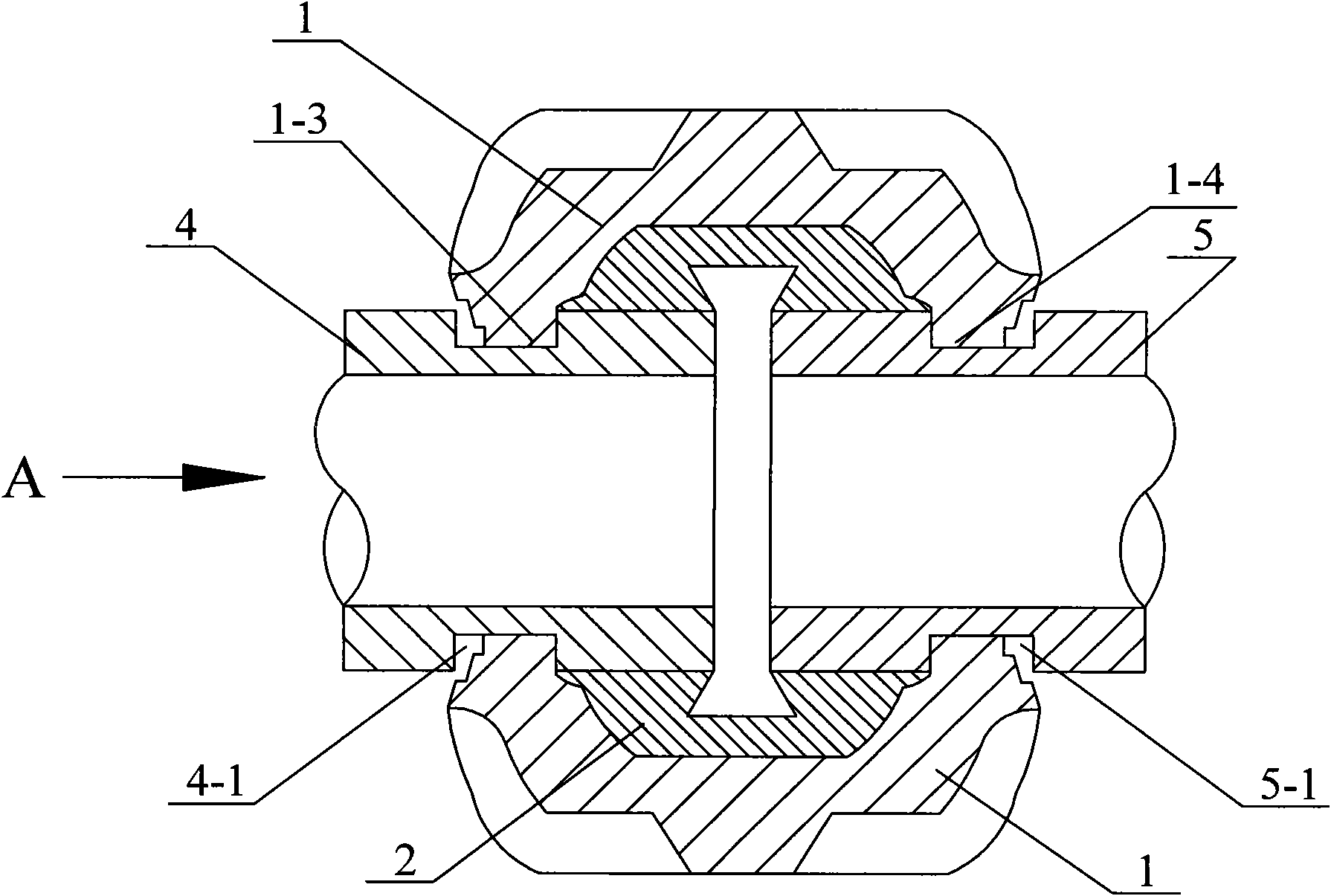

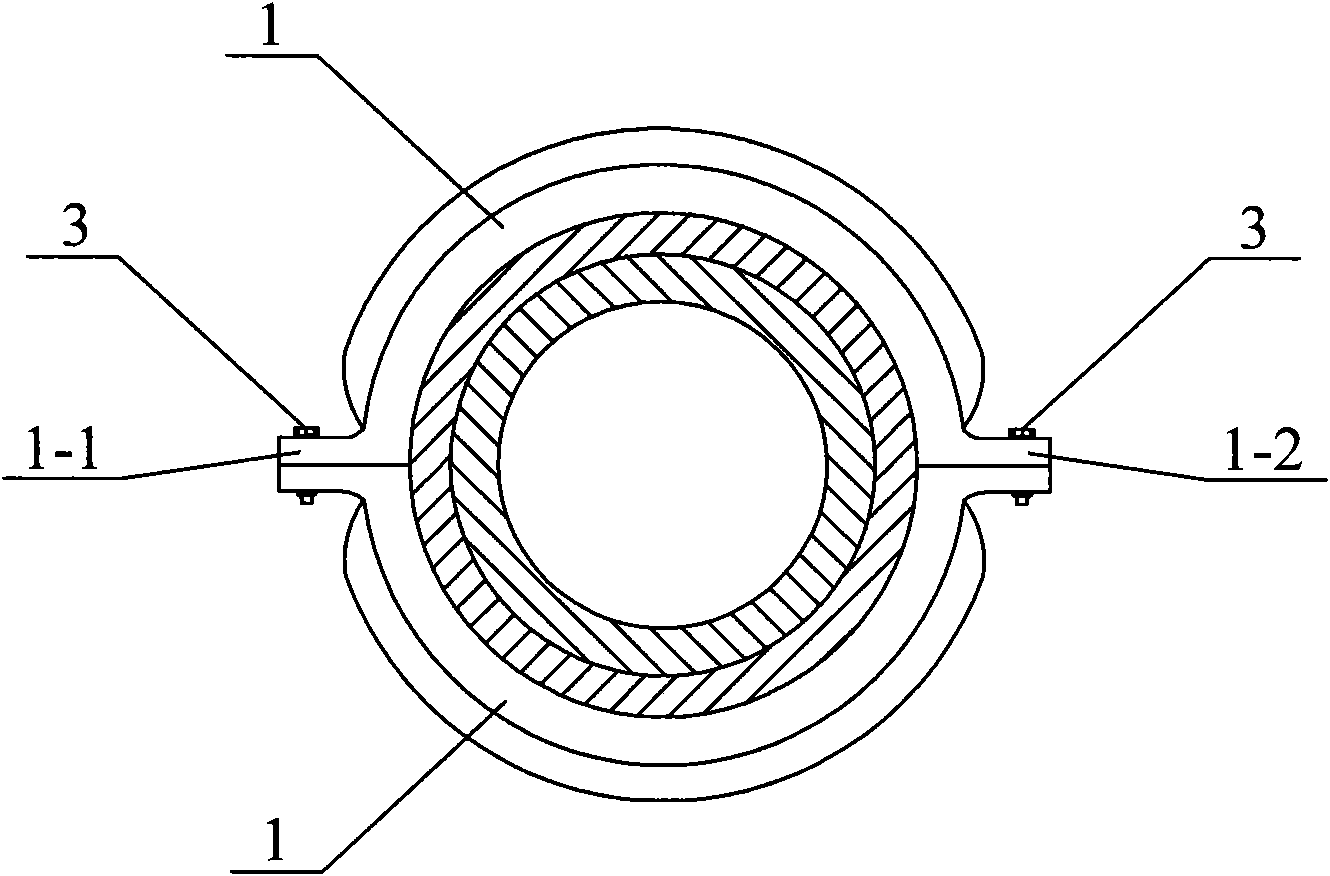

[0008] Such as figure 1 and figure 2 As shown, the grooved clamp type pipeline joint includes two semi-circular arch clamps 1, a sealing washer 2 and two fasteners 3, preferably, the fasteners 3 in this embodiment are fastening bolts .

[0009] The two ends of each semicircular arched clip 1 are respectively provided with outwardly protruding fastener connecting lugs 1-1 and 1-2; along the lower edges of the two sides of the semicircular arched clip 1, Flanges 1-3 and 1-4 extending downward are provided, and a groove is provided between the flanges 1-3 and 1-4, and two semicircular arched hoop pieces 1 are combined to form a sealing gasket for installation groove.

[0010] Before installing the grooved clamp type pipeline joint, first process the annular grooves 4-1 and 5-1 on the outer walls of the flat end joints of the two pipe fittings 4 and 5 respectively; Put the sealing gasket 2 on the pipe end; then use two semi-circular arched clamps 1 to join together, and at th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com