Electrode assembly

A technology of electrode assembly and discharge end, which is applied in the field of electrode assembly, can solve problems such as temperature increase, weakening arc tube temperature, and affecting lamp performance, so as to ensure the working pressure and increase the temperature of the cold end.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

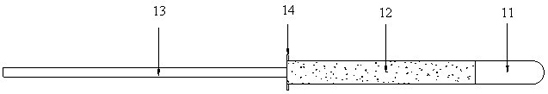

[0038] Example 1 150W ceramic metal halide lamp three-segment electrode, such as figure 2 , the specific dimensions of each part of the electrode assembly described in this embodiment are: the diameter of the tungsten mandrel is ΦA1: 1.2mm, the length A1: 6.0mm, the discharge end of the tungsten mandrel is semicircular; the diameter of the cermet rod is ΦA2: 1.2mm, Length A2: 13mm; outer lead diameter ΦA3: 0.8mm, length A3: 11.5mm, two positioning pieces are welded at the end of the cermet. All parts are laser welded.

Embodiment 2

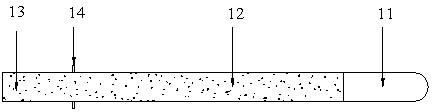

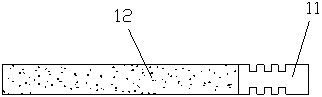

[0039]Example 2 150W ceramic metal halide lamp two-stage electrode, such as image 3 , the specific dimensions of each part of the electrode assembly described in this embodiment are: tungsten electrode diameter ΦB: 1.2mm, length B1: 6.0mm, electrode head is semicircular; cermet rod diameter ΦB: 1.2mm, B2: length 18mm The limiting structure is located 6 mm away from the top of the cermet rod. All parts are laser welded.

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com