A processing method for improving the surface hydrophobicity of masson pine wood

A technology of wood surface and processing method, which is applied to wood processing appliances, impregnated wood, wood impregnation and other directions, can solve the problems of affecting the service life of processing performance, damaged and broken fiber structure, and increased roughness of wood, etc., and achieves easy production process. Control, hydrophobicity enhancement, the effect of solving unfavorable problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

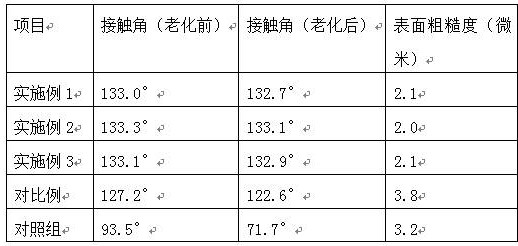

Examples

Embodiment 1

[0019] A processing method for improving the surface hydrophobicity of masson pine wood, which is specifically realized by the following process steps:

[0020] The masson pine wood in Henan area is used as the material. After the masson pine wood is cut according to the processing and production requirements, the surface of the masson pine wood is polished, and the surface debris is blown off with compressed air to obtain a finished workpiece. The loose workpiece is placed in a heat treatment box, completely soaked in the hydrophobic treatment agent, heated to 40°C at a rate of 0.8°C / min, sealed and kept for 60 minutes, continued to heat up to 50°C, sealed and kept for 30 minutes, and finally heated to 70°C. Seal and keep warm for 15 minutes, after natural cooling, take out the workpiece, put it in a constant temperature and humidity environment, the temperature is 24°C, the relative humidity is 63°C, and it can be air-dried for 5 hours.

[0021] The preparation method of the...

Embodiment 2

[0028] A processing method for improving the surface hydrophobicity of masson pine wood, which is specifically realized by the following process steps:

[0029] The masson pine wood in Henan area is used as the material. After the masson pine wood is cut according to the processing and production requirements, the surface of the masson pine wood is polished, and the surface debris is blown off with compressed air to obtain a finished workpiece. The loose workpiece is placed in a heat treatment box, completely soaked in the hydrophobic treatment agent, heated to 42°C at a rate of 0.9°C / min, sealed and kept for 65 minutes, continued to heat up to 53°C, sealed and kept for 35 minutes, and finally heated to 72°C. Seal and keep warm for 18 minutes, after natural cooling, take out the workpiece, put it in a constant temperature and humidity environment, the temperature is 25°C, the relative humidity is 64°C, and it can be air-dried for 7 hours.

[0030] The preparation method of the...

Embodiment 3

[0037] A processing method for improving the surface hydrophobicity of masson pine wood, which is specifically realized by the following process steps:

[0038] The masson pine wood in Henan area is used as the material. After the masson pine wood is cut according to the processing and production requirements, the surface of the masson pine wood is polished, and the surface debris is blown off with compressed air to obtain a finished workpiece. The loose workpiece is placed in a heat treatment box, completely soaked in the hydrophobic treatment agent, heated to 45°C at a rate of 1.0°C / min, sealed and kept for 70 minutes, continued to heat up to 55°C, sealed and kept for 40 minutes, and finally heated to 75°C. Seal and keep warm for 20 minutes, after natural cooling, take out the workpiece, put it in a constant temperature and humidity environment, the temperature is 26°C, the relative humidity is 65°C, and it can be air-dried for 10 hours.

[0039] The preparation method of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| whiteness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com