Patents

Literature

72results about How to "Flexible commutation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

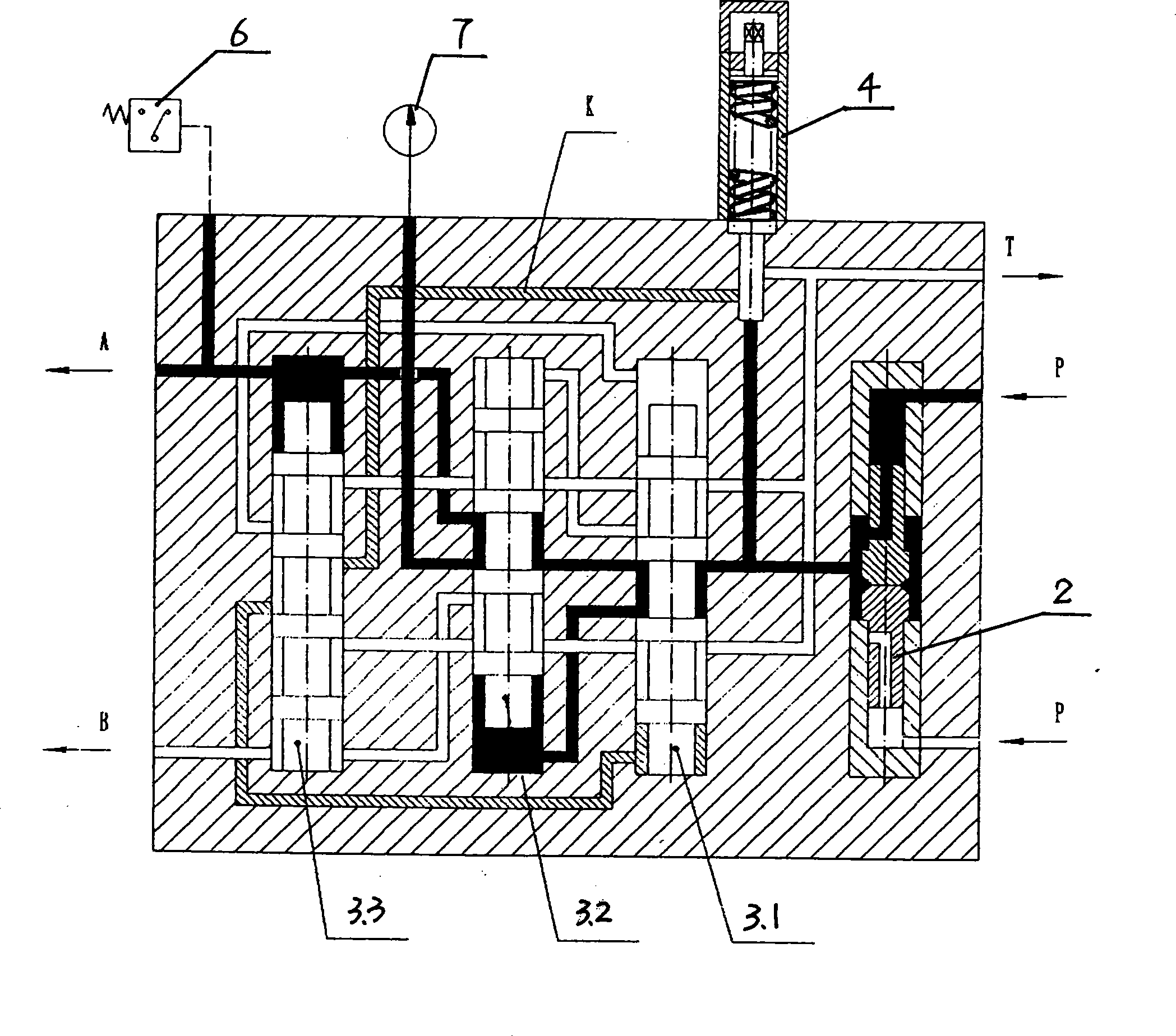

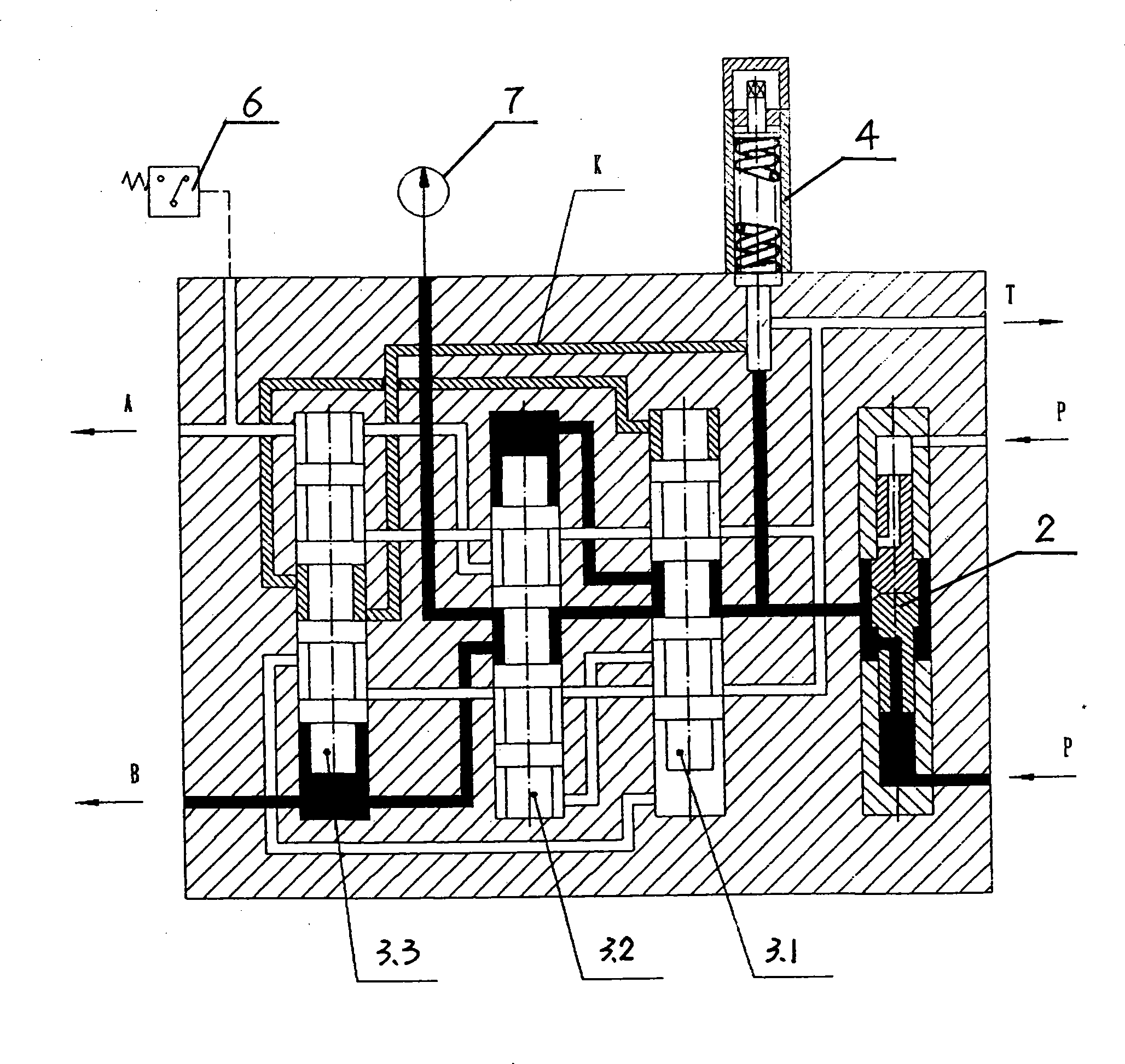

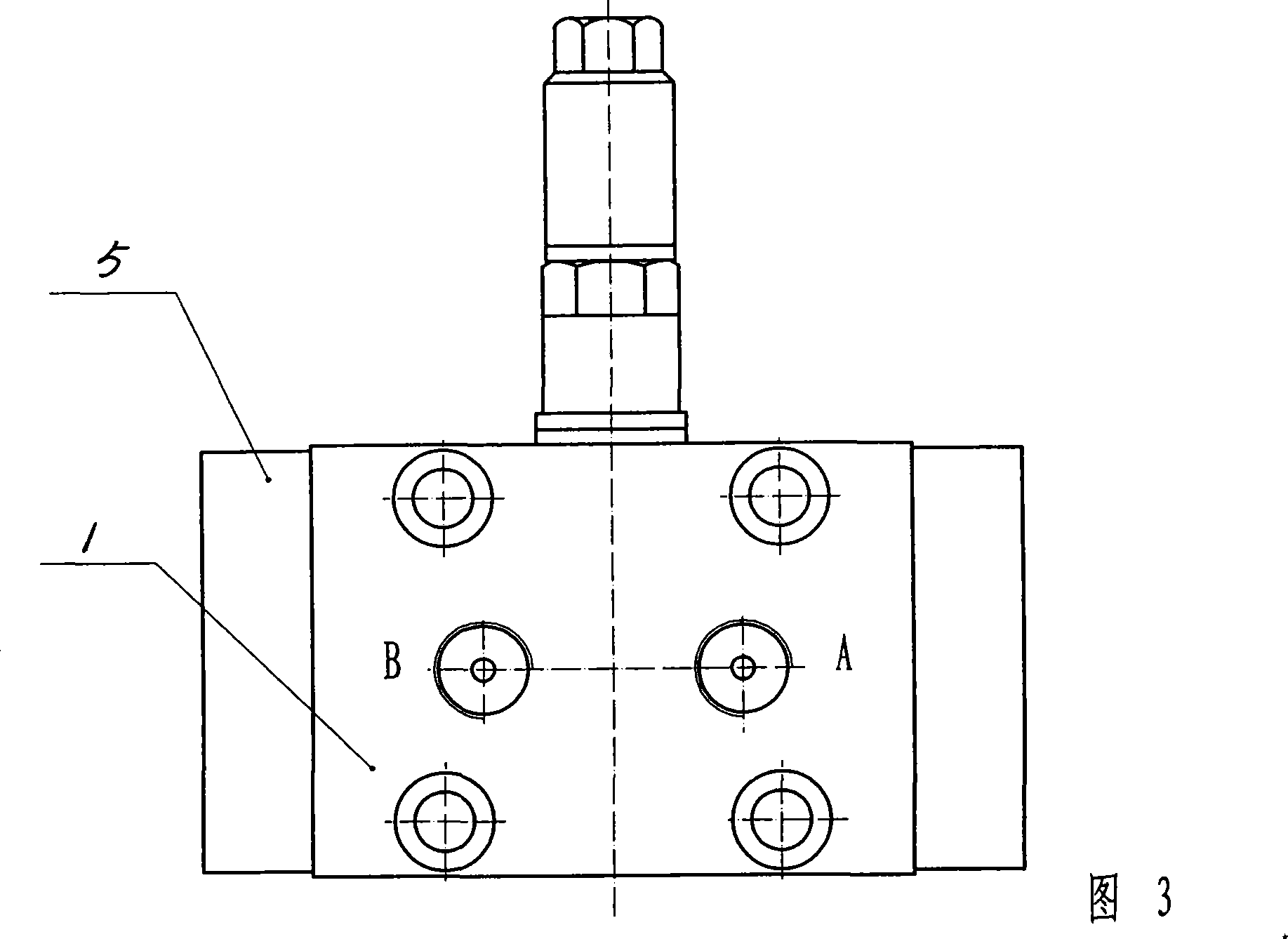

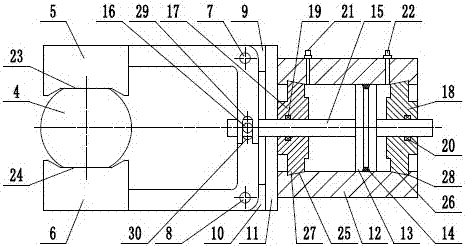

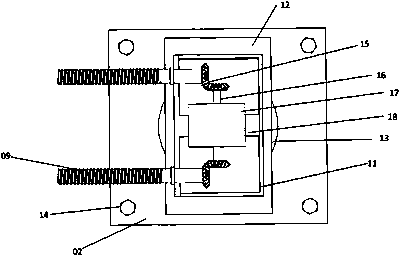

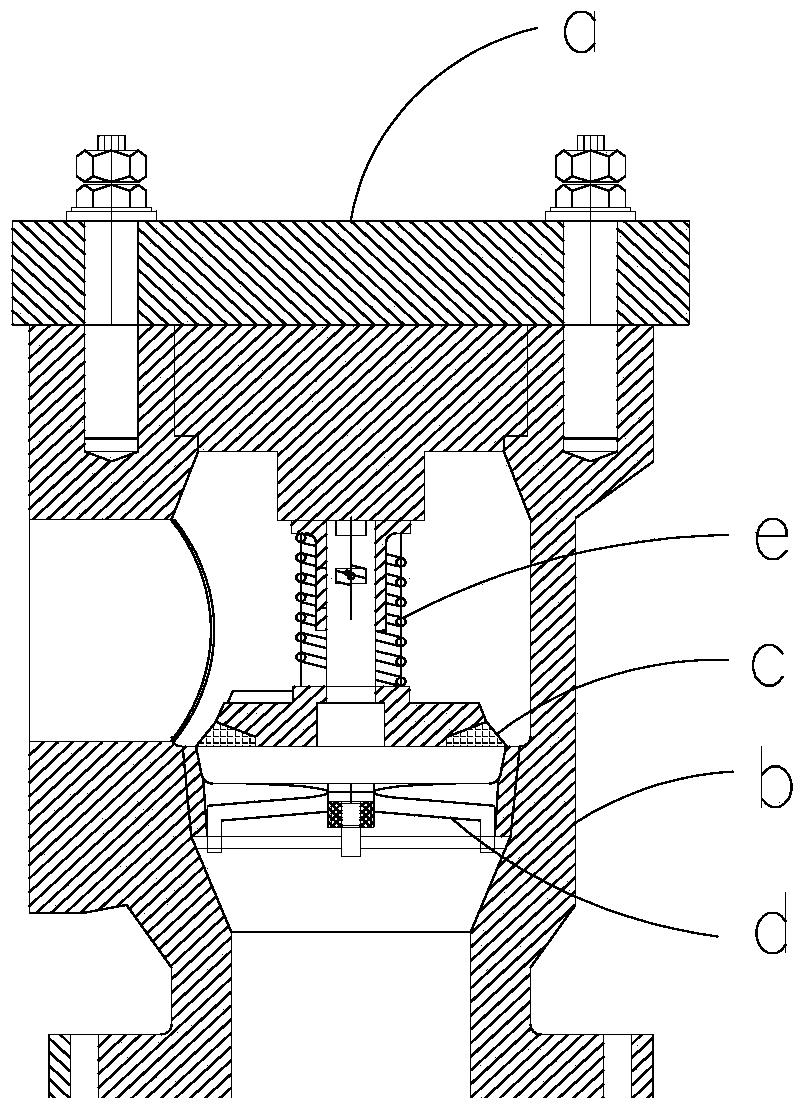

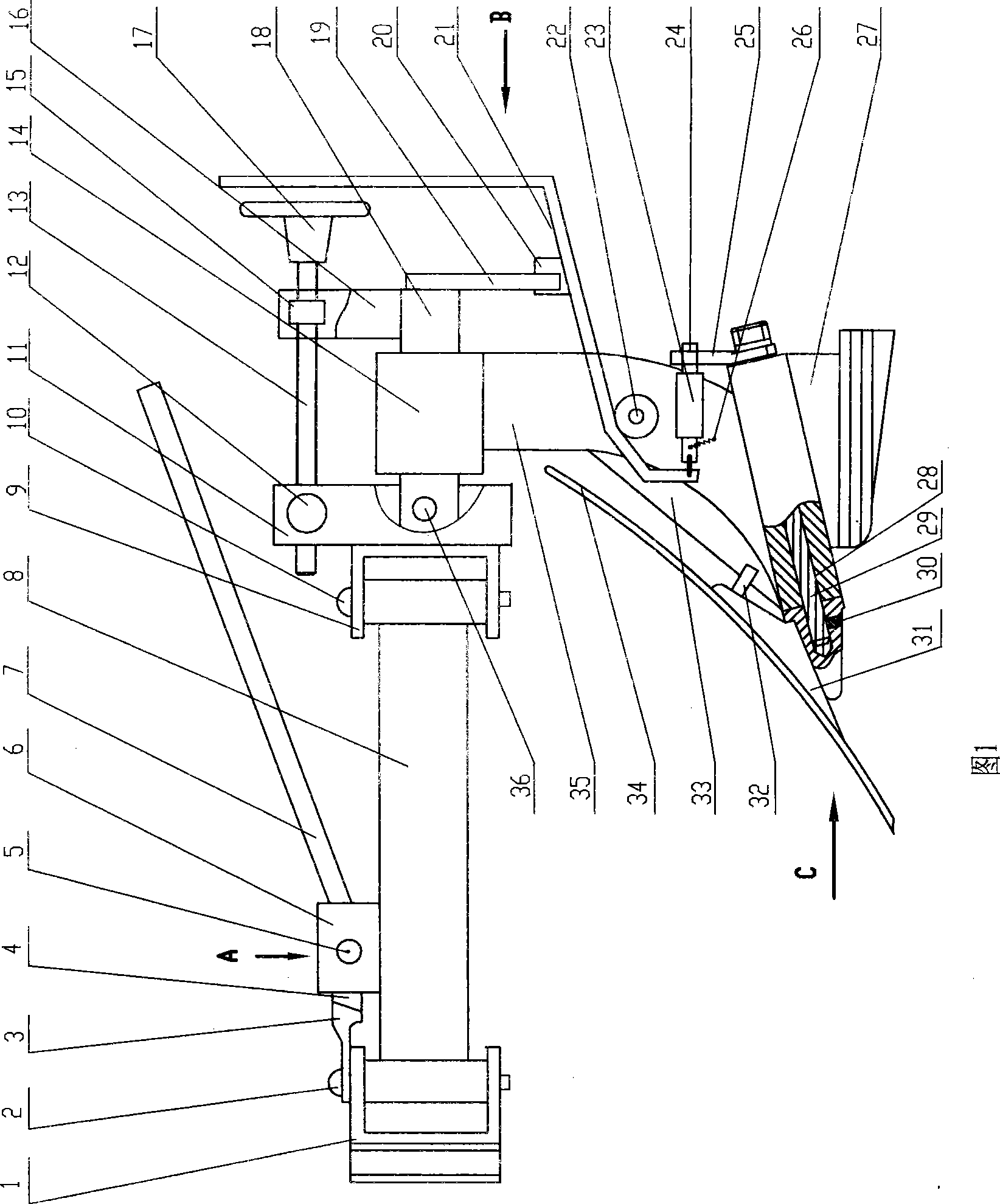

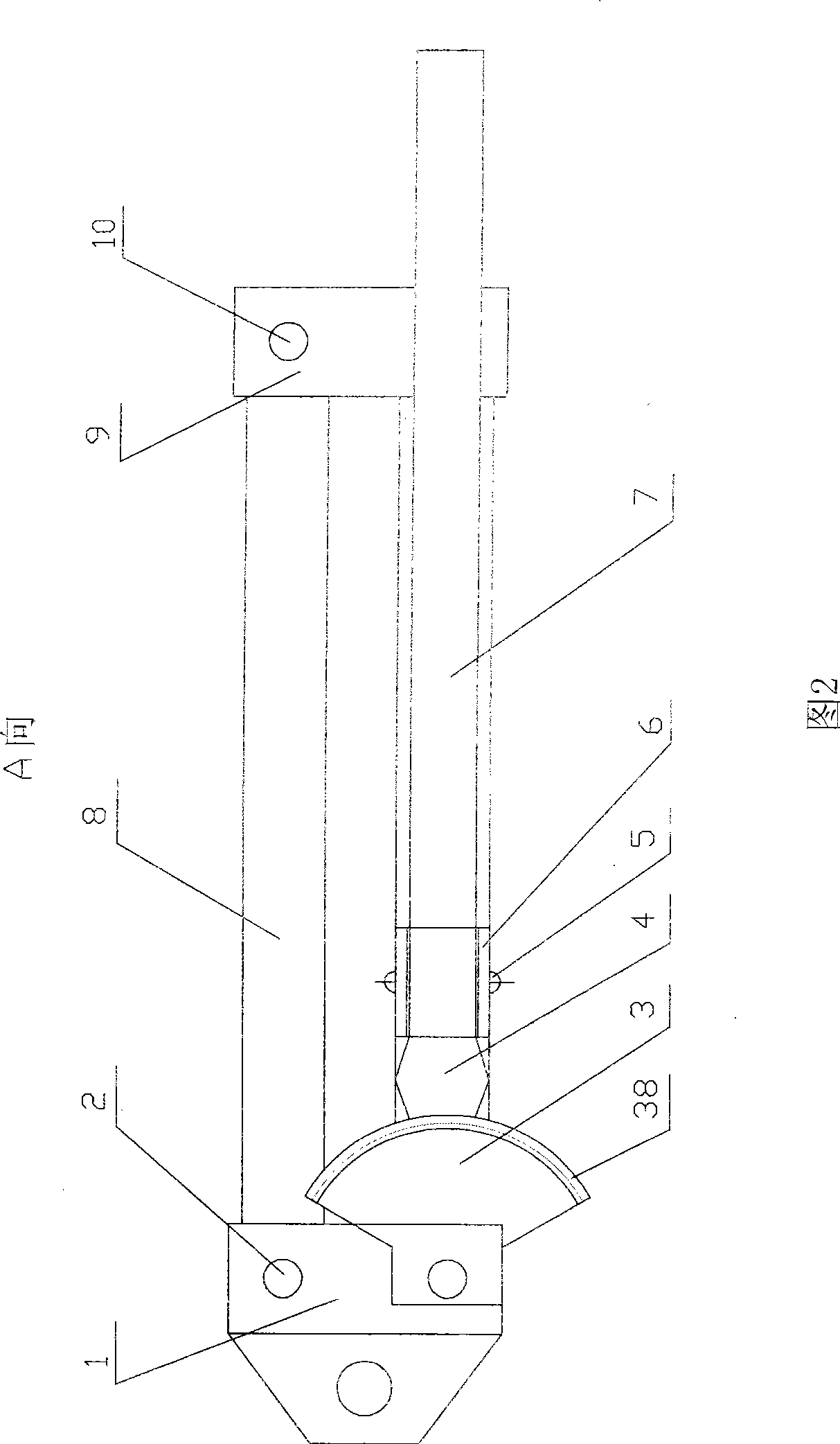

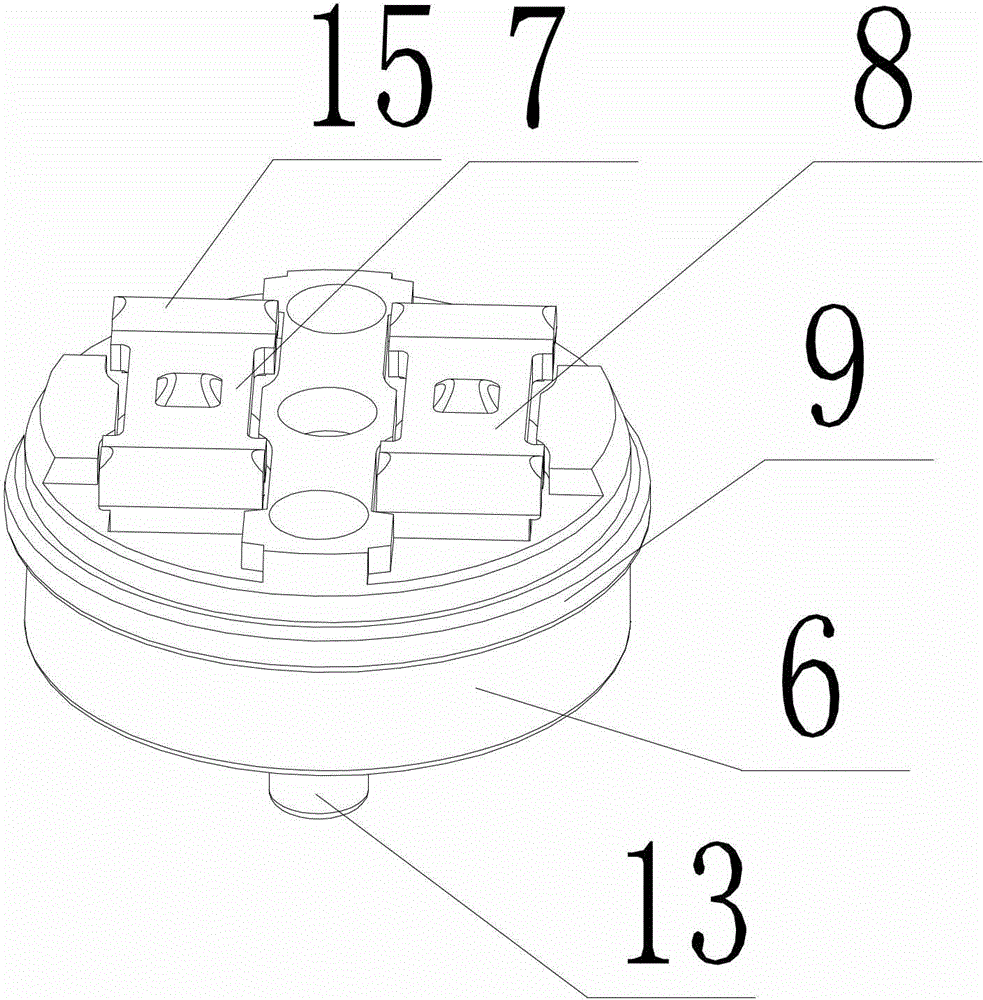

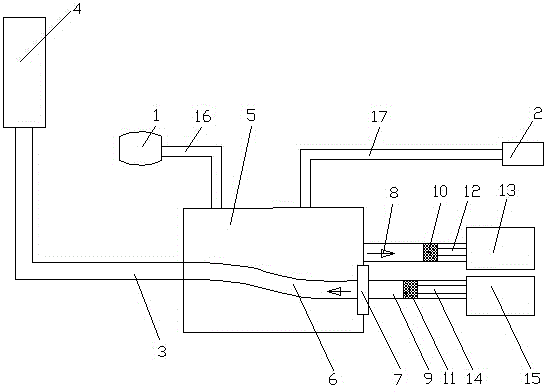

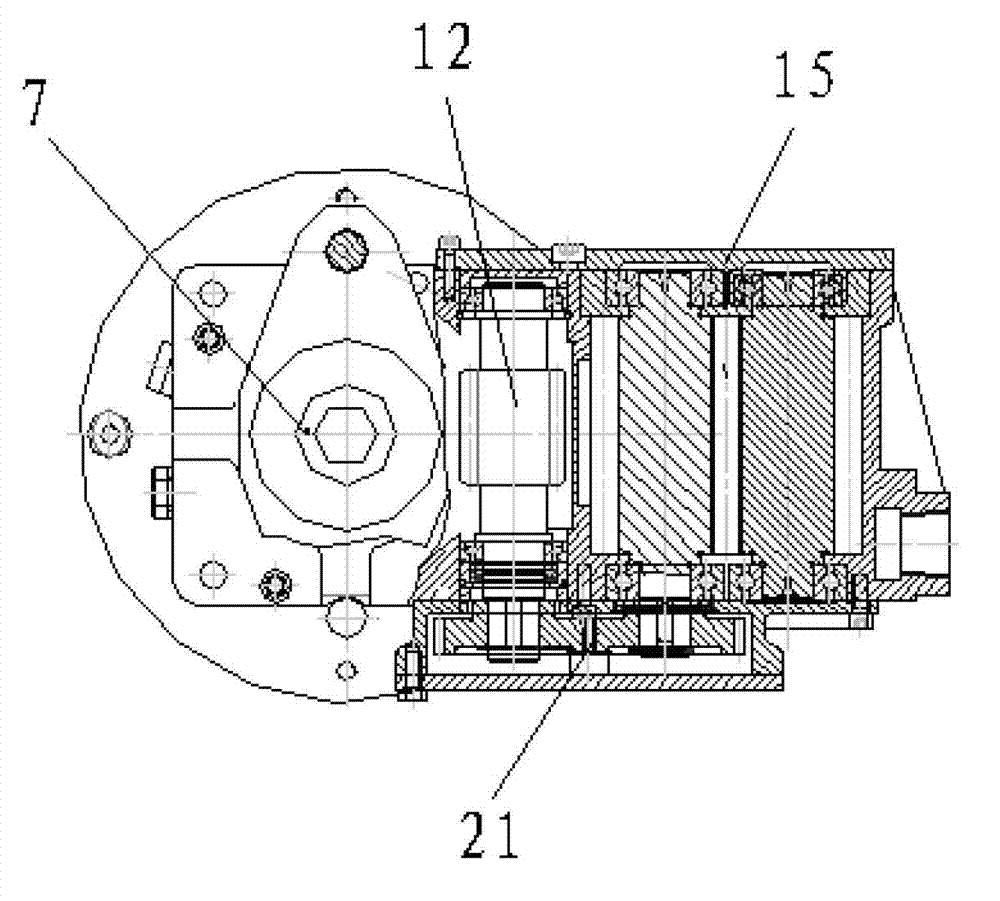

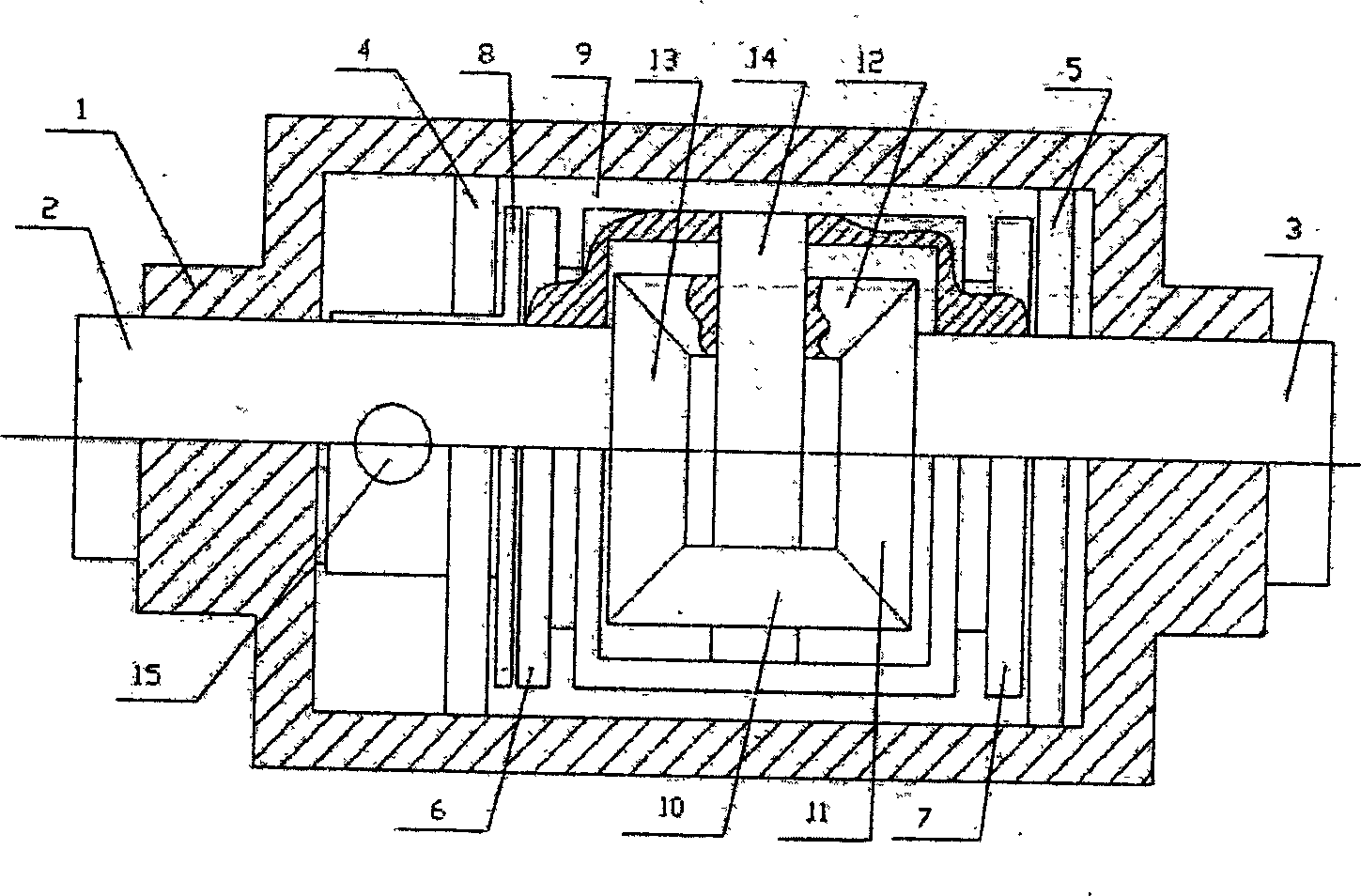

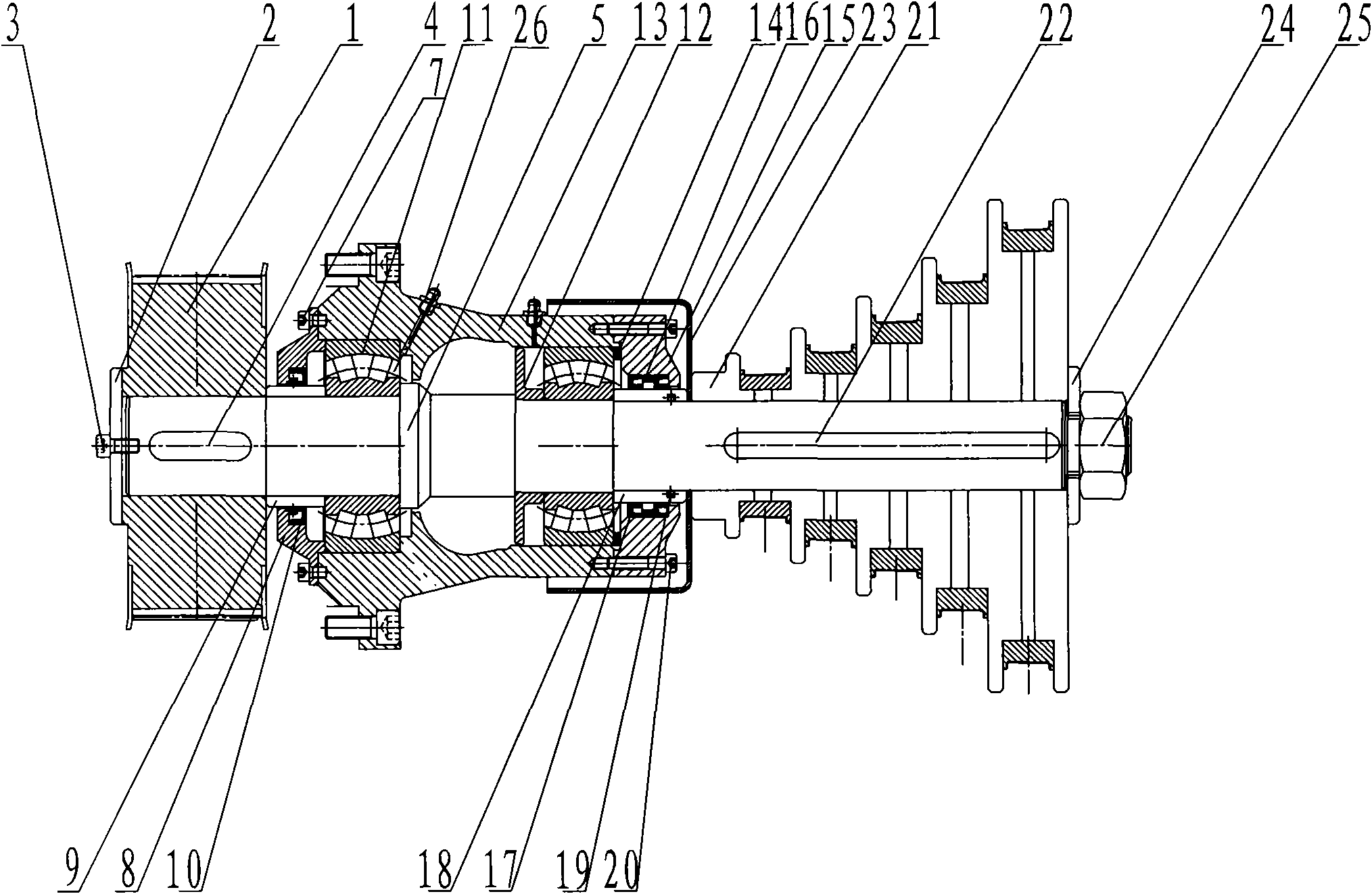

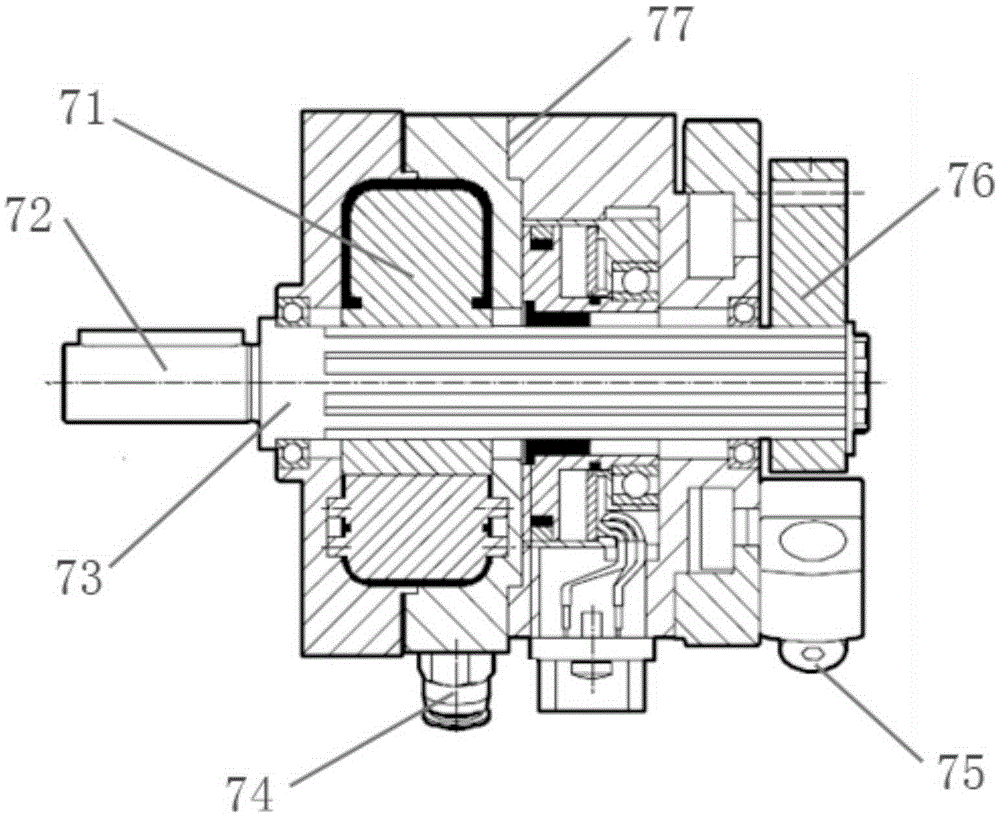

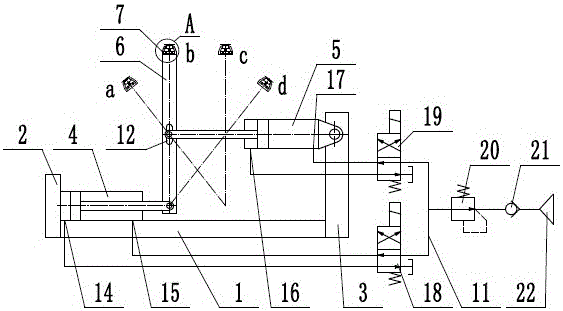

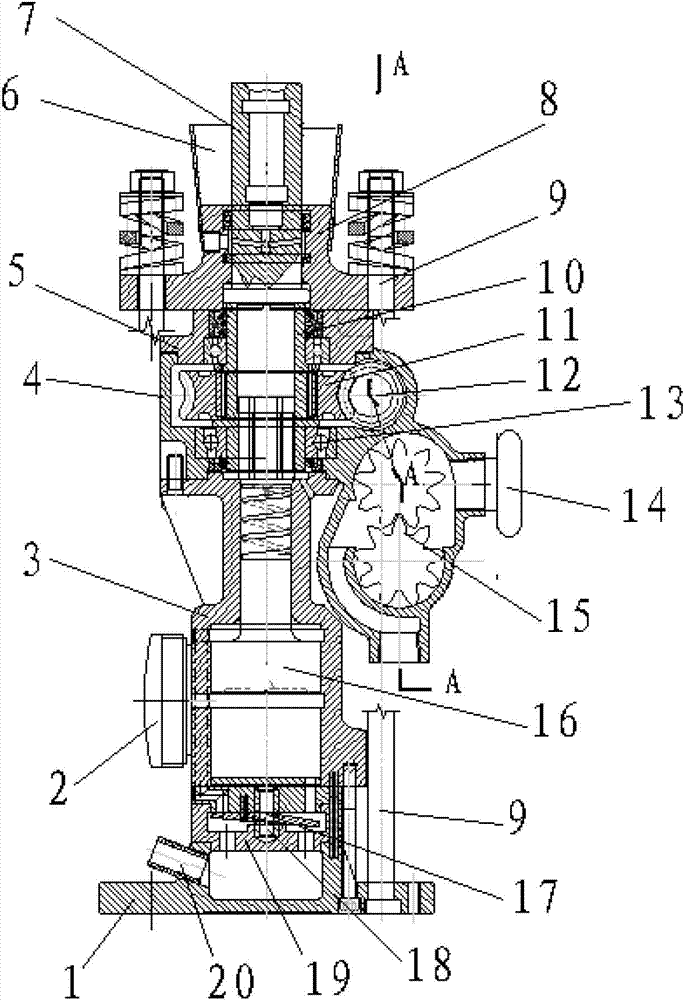

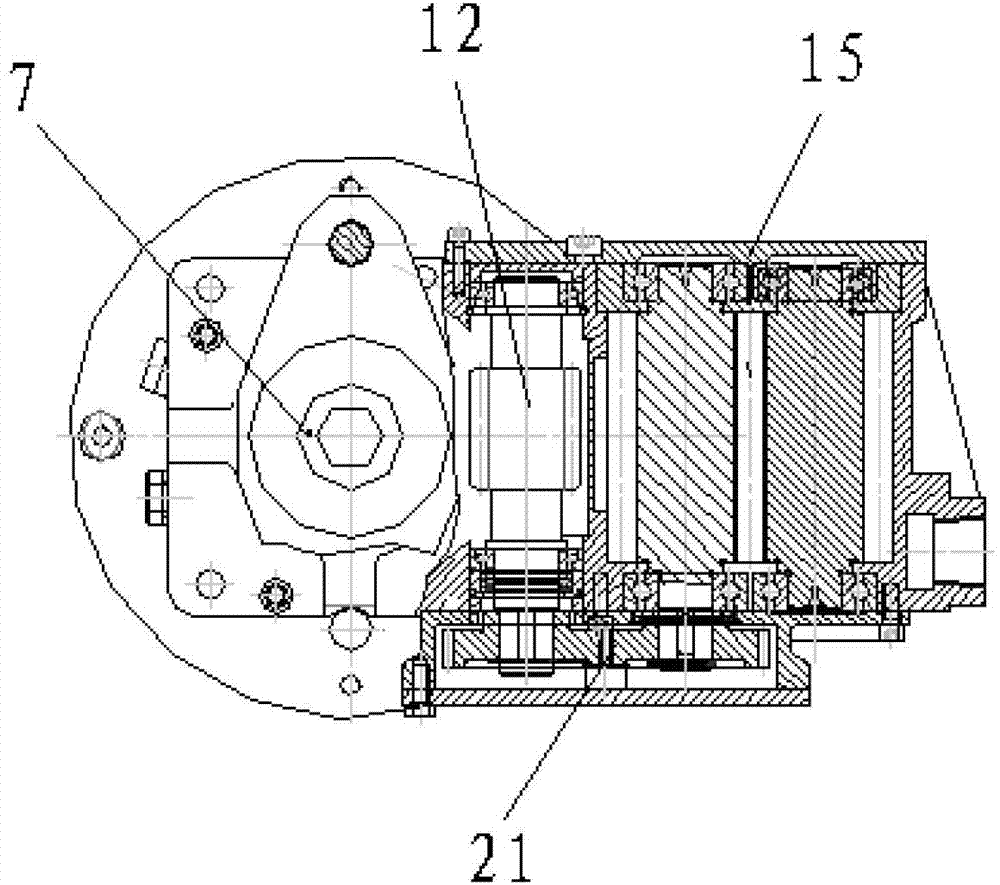

Hydraulic pressure pressure-regulating automatic reverse combined valve for double line grease lubricating system

InactiveCN101251225ALarge reversing pressure rangeFlexible commutationDistribution equipmentLubrication check valvesSpool valveCheck valve

The invention belongs to the hydraulic reversing valve technical field, particularly relates to an automatic hydraulic pressure-regulation reversing combination valve used for a double line grease lubricating system, and provides a reversing valve which is applicable to the grease supply of high-pressure electric grease pumps as well as middle and low pressure electric grease pumps. The automatic hydraulic pressure-regulation reversing combination valve used for a double line grease lubricating system comprises a valve body, the valve body is provided with two grease inlets and two grease outlets, and three reversing slide valves are arranged inside the valve body. The invention is characterized in that: two symmetrical plunger type grease distribution check valves are arranged between the grease inlets and the slide valves, the grease distribution check valves and a reversing slide valve grease path are connected with a pressure-regulation safety valve, and one grease outlet is provided with a pressure sensor interface. Compared with the prior art, the valve has the following advantages that: the valve adopts the hydraulic control to automatically change directions, is applicable to the lubrication systems less than 40MPa pressure, and has big reversing pressure-regulation range (from 3.5MPa to 35MPa), flexible direction change, no noise, strong anti-pollution capacity and reliable work.

Owner:义小毛

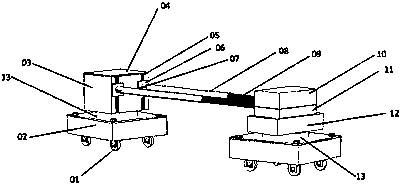

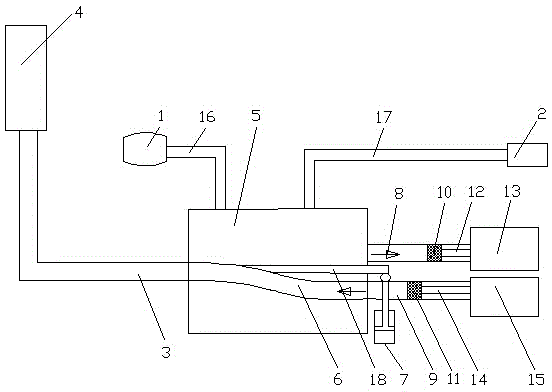

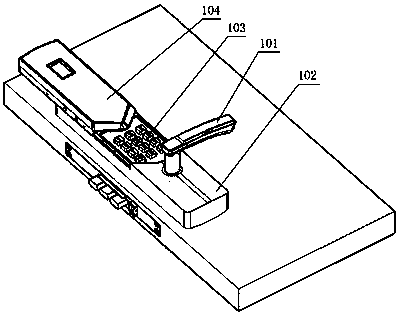

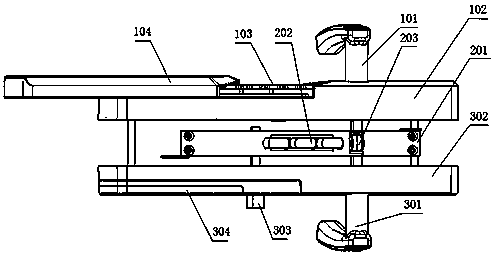

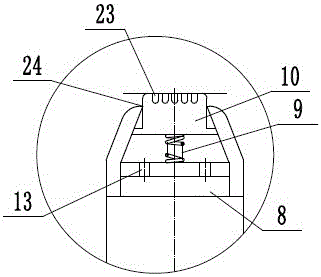

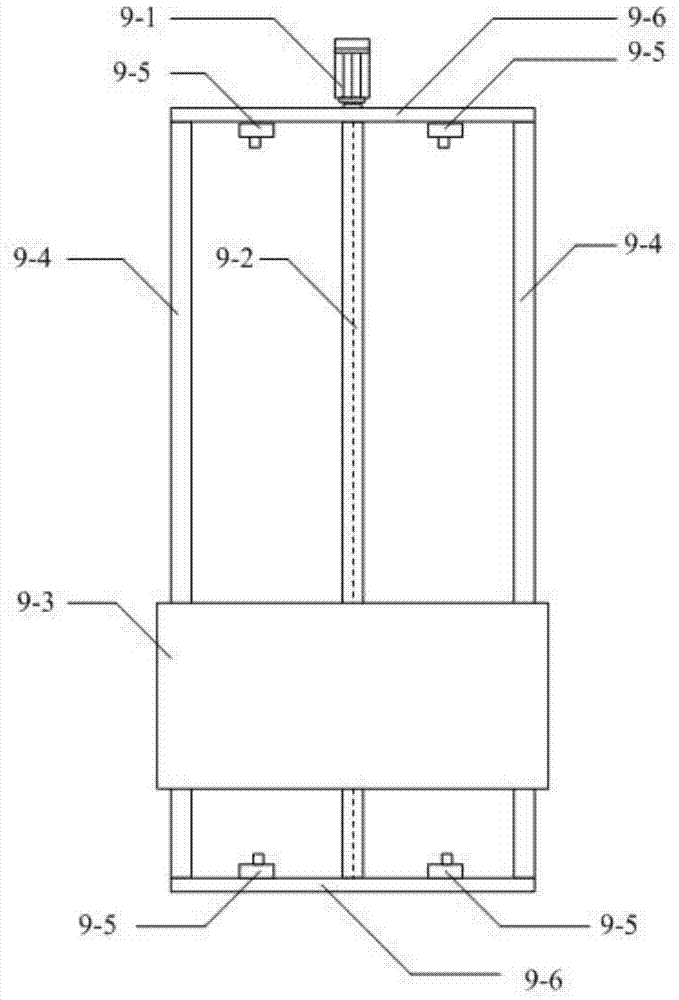

Assembling device for shaft end nuts

InactiveCN107309642AAchieve releaseAvoid moving back and forthMetal working apparatusEngineeringCylinder block

The invention provides an assembly device for a shaft end nut, which belongs to the technical field of shaft workpiece assembly. The piston of the clamping fastening mechanism is slidably arranged in the cylinder body, the driving pin is fixed at one end of the piston rod, the driving pin is inserted into the first open groove and the second open groove, and the guide rod and the guide sleeve of the shaft end nut tightening mechanism are up and down. Slidable connection, the upper end of the tightening piston rod is connected to the tightening support seat, the nut support seat is coaxially installed on the upper end of the second rotating shaft, the air pump of the pneumatic drive mechanism is connected to one end of the pressure regulating valve, and the other end of the pressure regulating valve is connected to the first three The first valve port of the one-position four-way reversing valve and the fifth valve port of the second three-position four-way reversing valve, the second valve port is connected to the first air valve on the cylinder body, and the third valve port is connected to the The second air valve, the sixth valve port is connected to the lower air valve of the tightening cylinder, and the seventh valve port is connected to the upper air valve of the tightening cylinder. The invention quickly realizes the clamping and fastening of the shaft, and realizes the automatic assembly of the nut at the shaft end, and has a reasonable structure.

Owner:TONGXIANG FENGMING TIN MAKING FACTORY

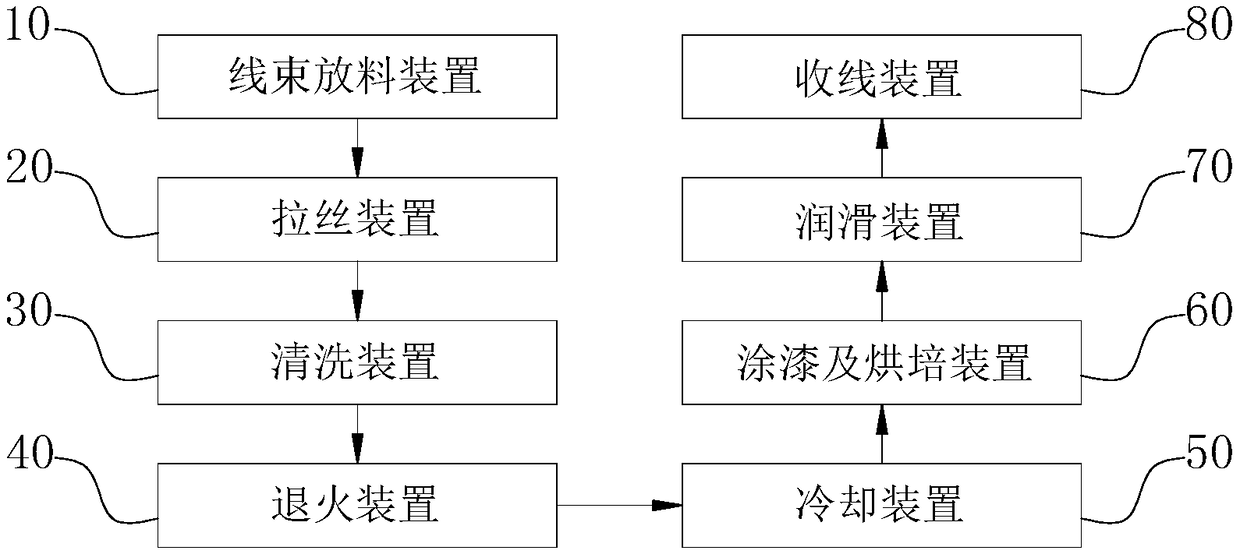

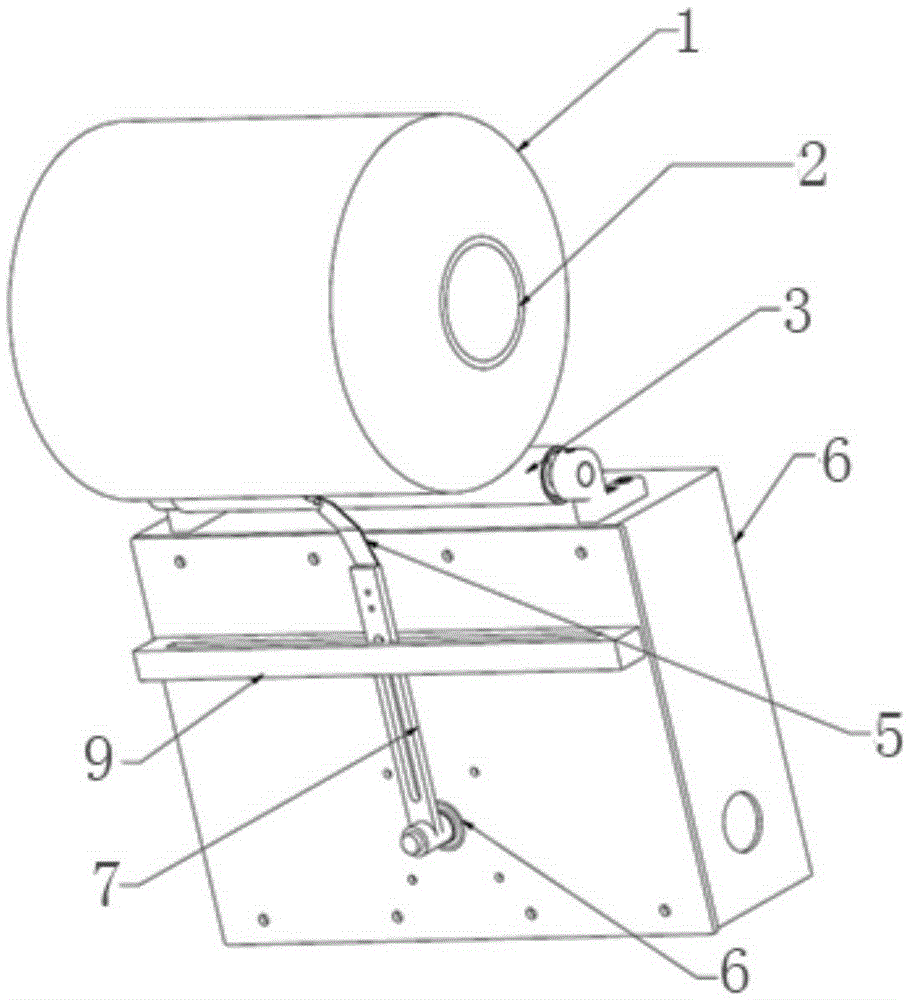

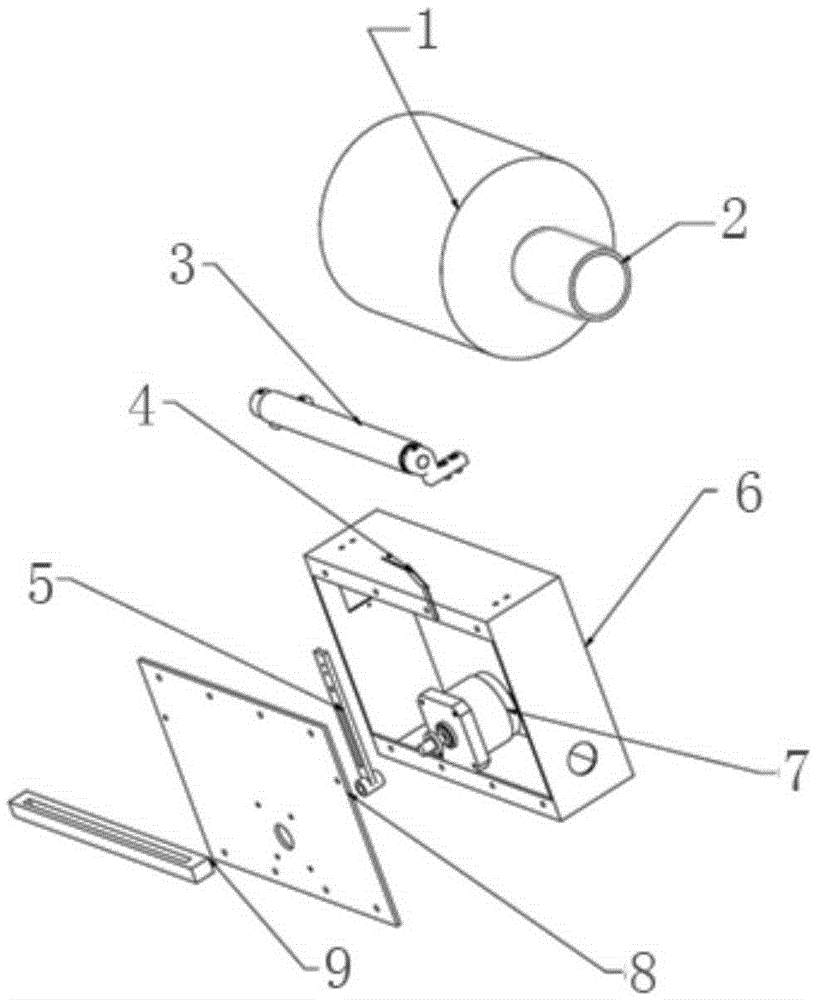

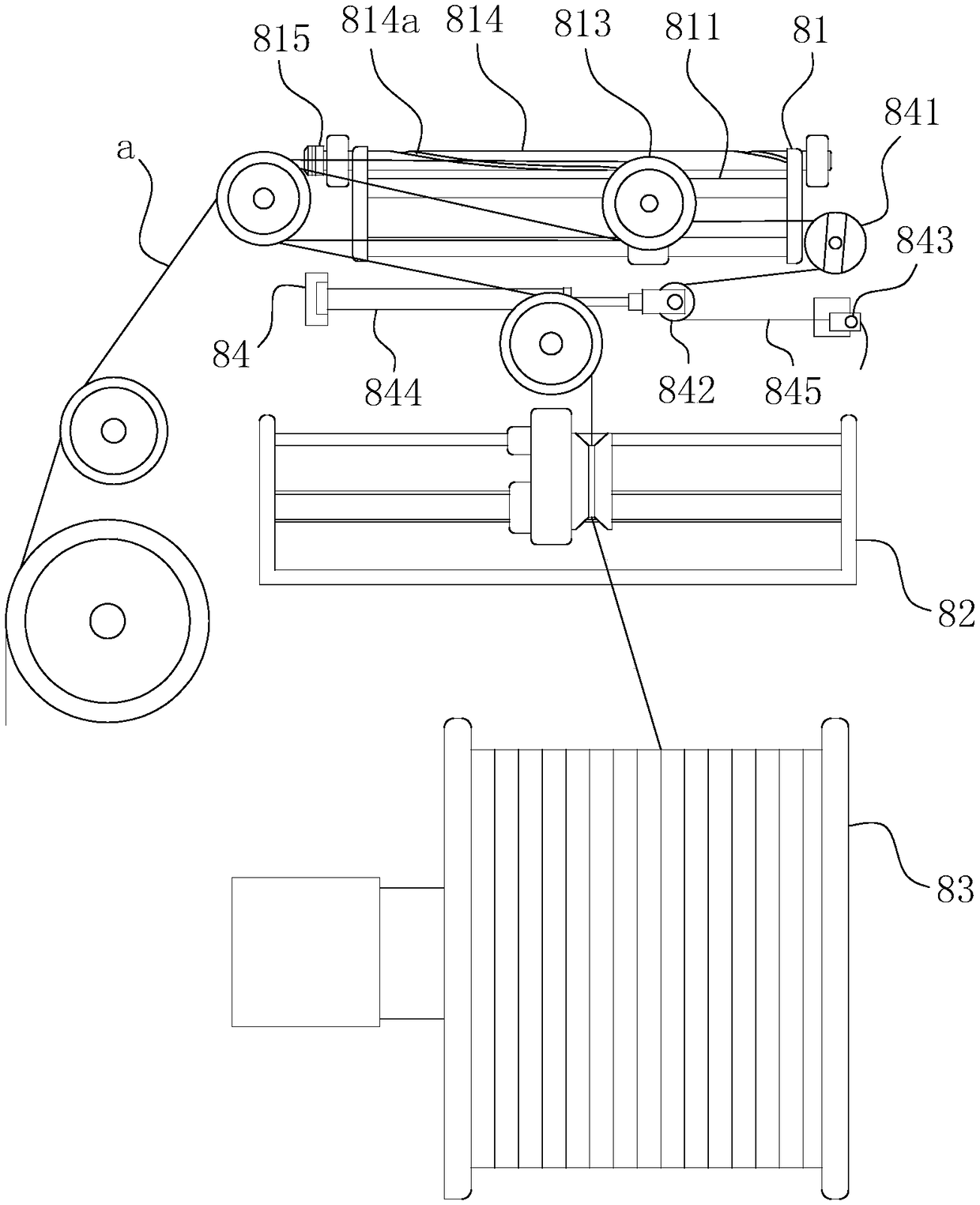

Enameled wire production line

ActiveCN109243705ARealize the purpose of normal line windingNo friction and wear problemsInsulating conductors/cablesCooking & bakingProduction line

The invention belongs to the technical field of enameled wire production, in particular to an enameled wire production line. A material discharge device of that wire harness is sequentially arranged along the travel direction of the copper wire in the production line; Wire drawing device; Cleaning device; Annealing device; Cooling device; Painting and baking equipment; Lubrication device; Take-updevice; The take-up device comprises a tensioning control assembly, a wire arrangement assembly and a take-up coil; The tensioning control module comprises a horizontal sliding guide rail, a guide block, a swing wheel and a follow-up rotating lever; A spiral groove is arranged at the body of the follower lever around the axis of the follower lever, the guide block extends toward the spiral grooveand is provided with a shift arm, and an extension of the shift arm extends into the spiral groove cavity; A rotary switch for monitoring the magnitude of rotation of the follower lever is arranged atthe lever end of the follower lever. The production line can effectively solve the problems of low service life and poor sensitivity of traditional proximity switches, and the production efficiency and finished product quality of enamelled wires can also be effectively improved.

Owner:TONGLING JINGXUN SPECIAL ENAMELLED WIRE

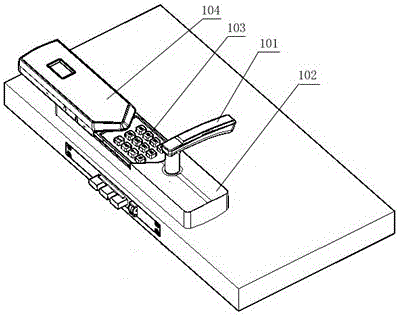

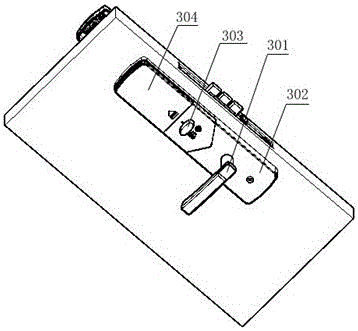

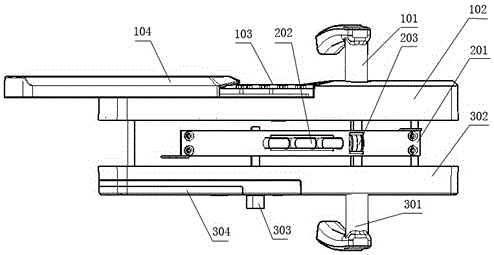

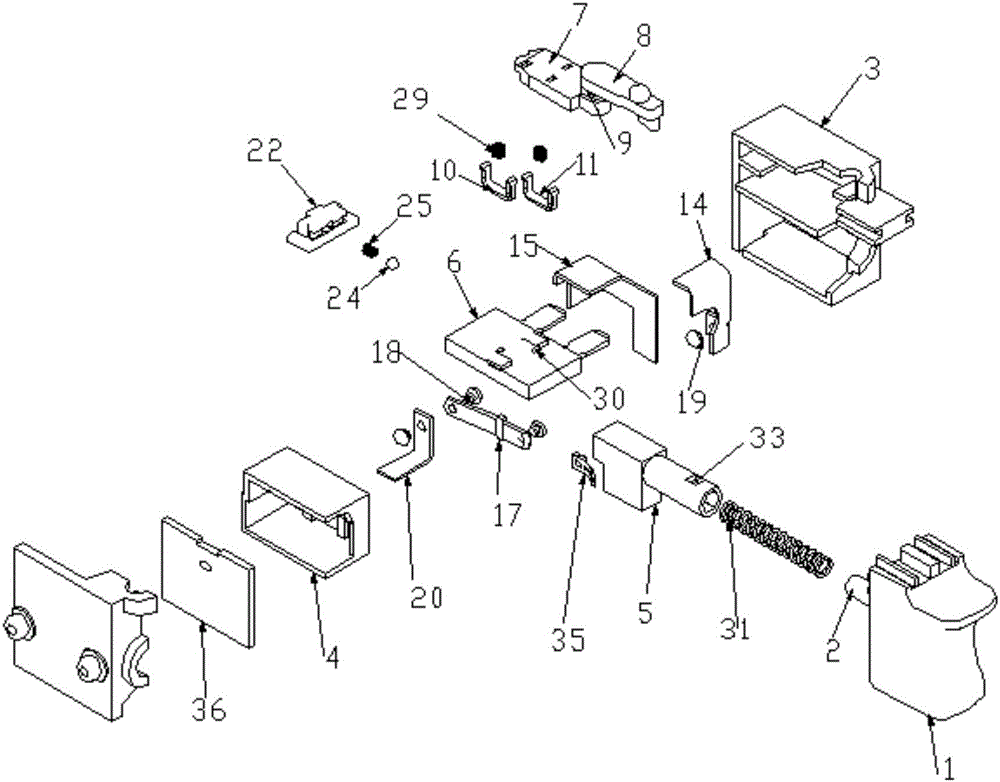

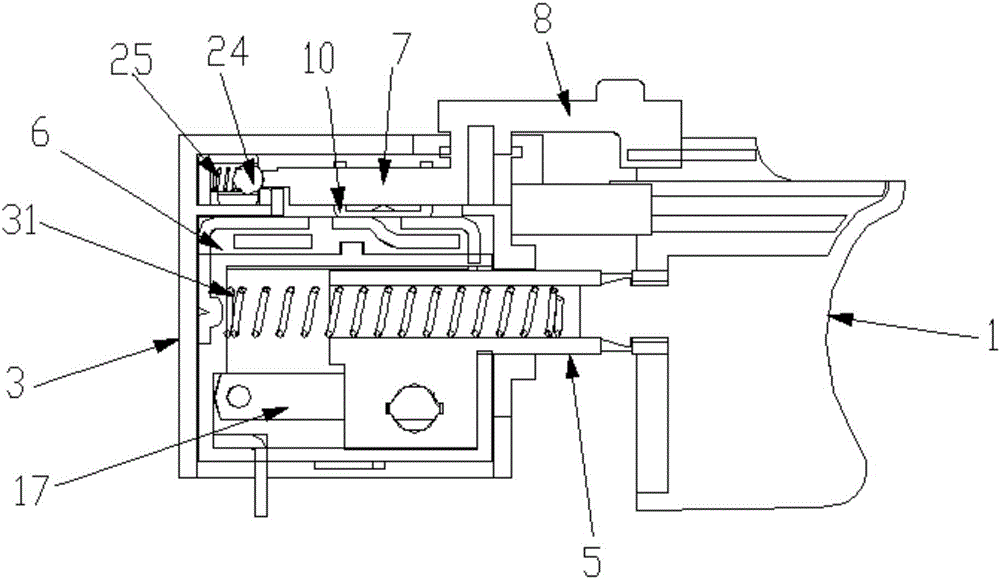

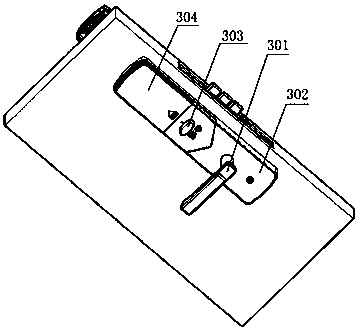

Combined coded lock

ActiveCN106121388AAvoid safety hazardsImprove securityElectric permutation locksLatching locksFingerprintAnti theft

The invention discloses a combined coded lock. The combined coded lock comprises an internal handle assembly, an external handle assembly and a lock body and further comprises an engagement-and-disengagement mechanism arranged on the external handle assembly and a drive mechanism for driving the engagement-and-disengagement mechanism. The lock body comprises a lock shell, lock tongues and a linkage mechanism for driving the lock tongues to move. The external handle assembly can selectively drive the linkage mechanism through the engagement-and-disengagement mechanism. The internal handle assembly is connected with the linkage mechanism and can directly drive the linkage mechanism. The combined coded lock has the beneficial effects that a fingerprint code lock body and a touch-tone mechanical coded lock body are combined to serve as a double-driver of the coded lock, the potential safety hazards brought by a traditional mechanical lock are avoided, and the safety of the coded lock is improved. Furthermore, the combined coded lock is further provided with a handle reversing gear, and mounting is flexible; and the linkage mechanism is in cooperation with the double-drive mechanism and the engagement-and-disengagement mechanism to form a complete structure, and the demands of people on the high safety of anti-theft locks, convenient and fast use, flexible mounting and the like can be well met.

Owner:徐州宇之阳市场营销策划有限公司

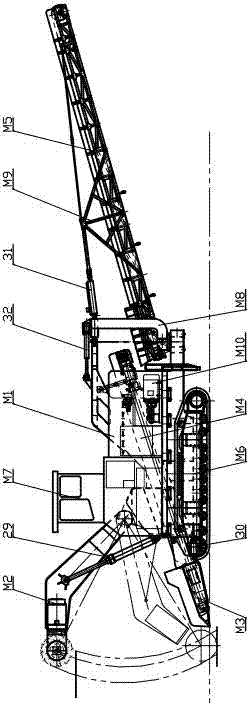

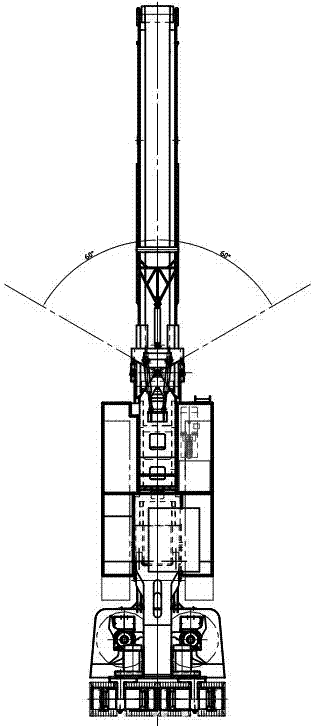

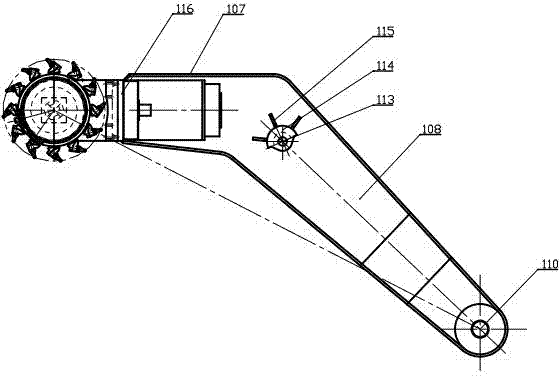

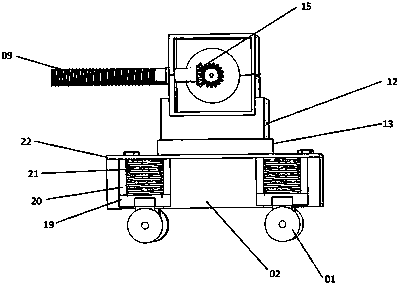

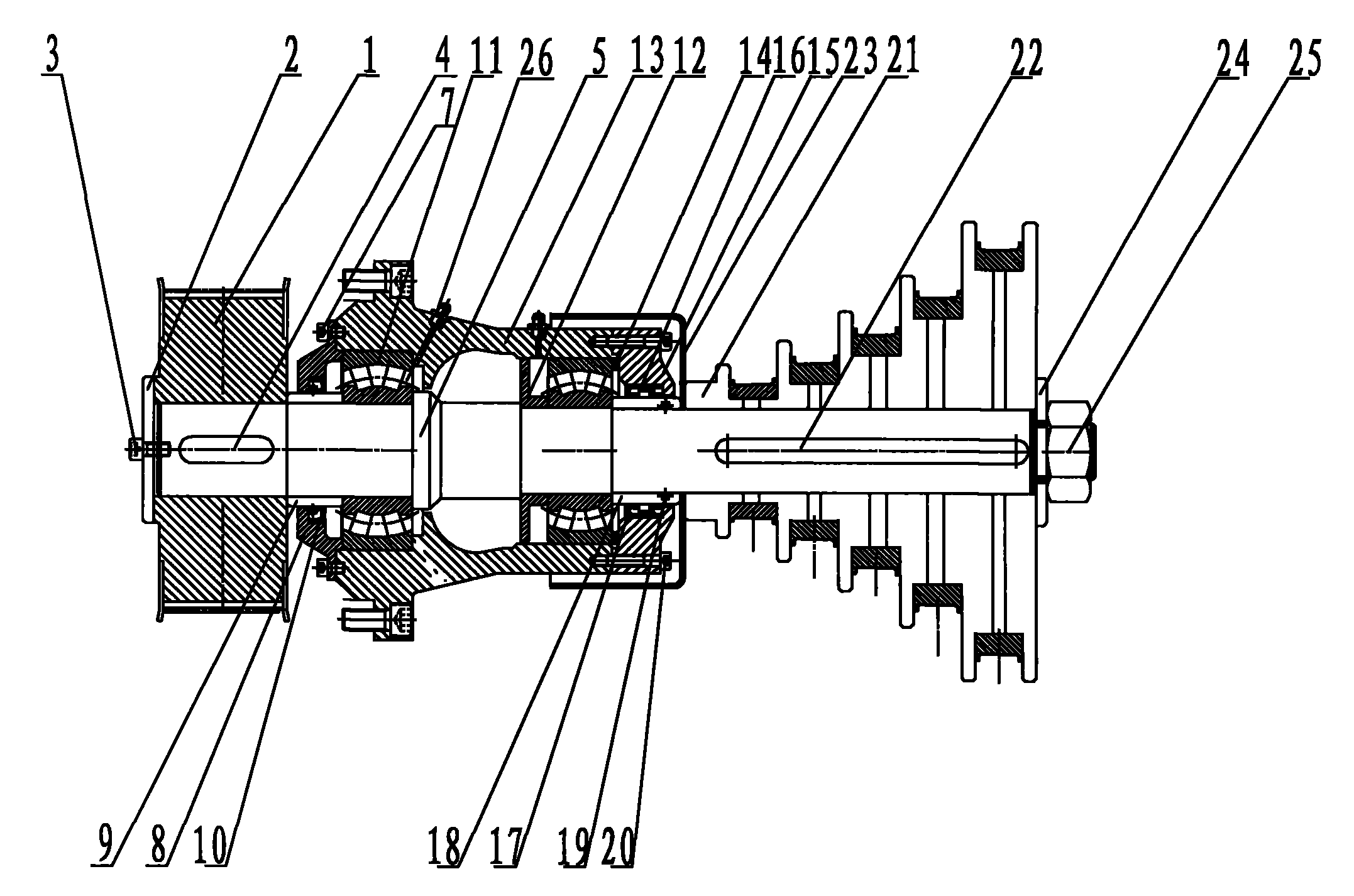

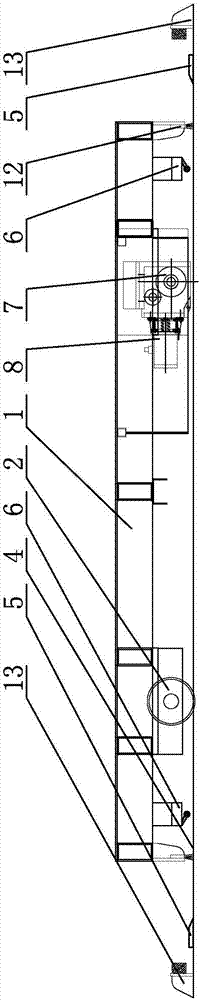

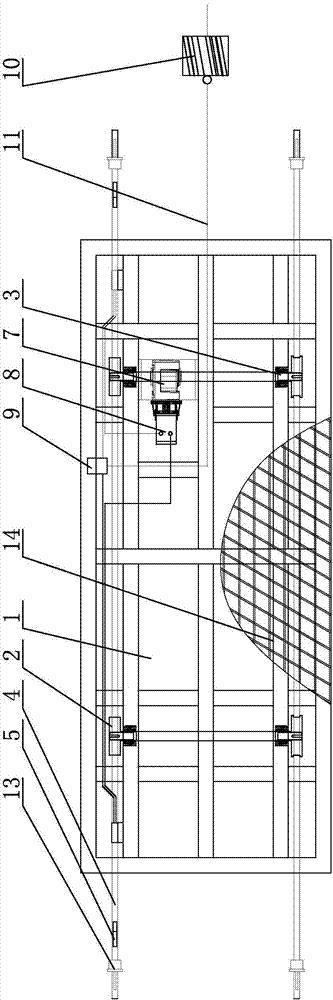

Roll-cutting type continuous mining machine

InactiveCN103775087AReasonable designImprove work efficiencyOpen-pit miningHydraulic motorVehicle frame

A roll-cutting type continuous mining machine comprises a car frame body, a cutting mechanism, a star wheel type loading mechanism, a scraper conveyor, a belt conveyer, an operating arm lifting oil cylinder, a belt conveyer rotary oil cylinder, a belt conveyer lifting oil cylinder, a hydraulic control system, a power supply system and a PLC (Program Logic Controller) control system, wherein the car frame body is equipped with a travel pedrail assembly and a cab, and the travel pedrail assembly comprises a left travel motor and a right travel motor; the scraper conveyor is obliquely mounted, the rear end of the scraper conveyor is hinged onto the car frame body, and a drive roller of the scraper conveyor is driven by a scraper hydraulic motor; the star wheel type loading mechanism is mounted at the front end of the scraper conveyor; a shoveling plate lifting oil cylinder is arranged between the star wheel type loading mechanism and the car frame body; a star wheel of the star wheel type loading mechanism is driven by the star wheel hydraulic motor. The mining machine not only can achieve continuous operation of cutting and loading, and has the advantages of large mining area, high mining working efficiency, low fault rate, less dust in the mining process, long service life and the like.

Owner:FUJIAN TIANJUN IND

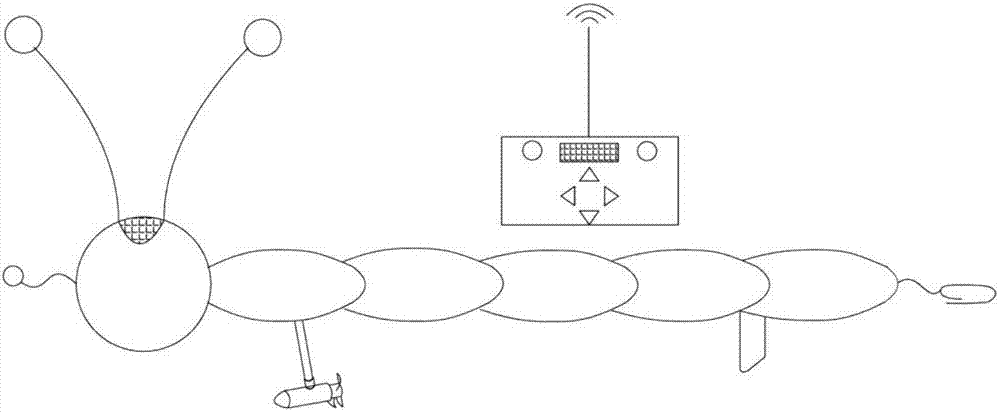

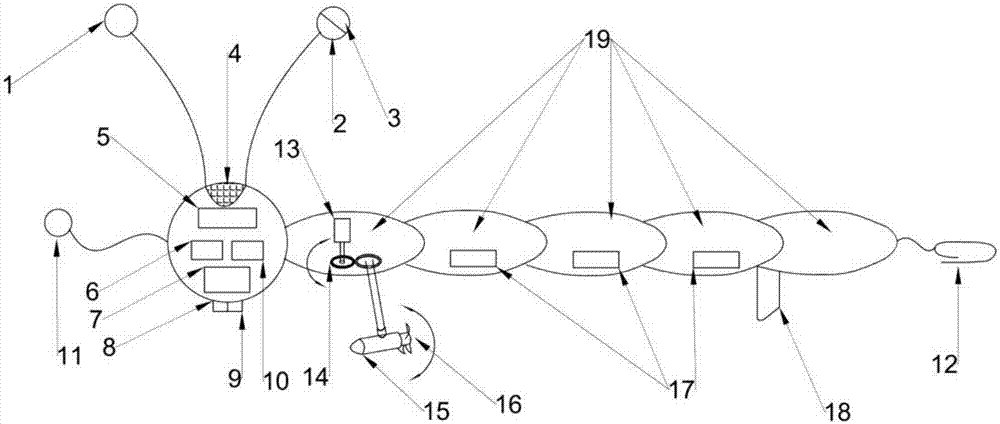

Self-searching type bionic intelligent life buoy

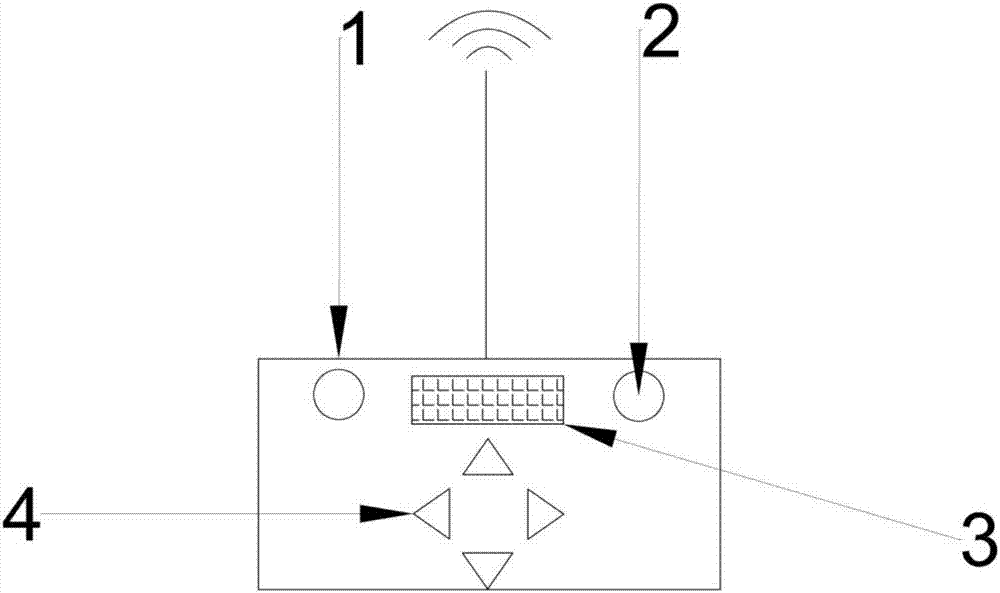

PendingCN107416148ARealize self-navigation functionReduced forward resistanceLife-buoysVessel signalling devicesWireless transceiverTransceiver

The invention discloses a self-seeking bionic intelligent lifebuoy. The lifebuoy is charged by solar energy and is in the shape of a long strip, which can be connected end to end to form a circle. It is designed in sections, and if one section is damaged and leaks air, the whole can still be used. The design of water pressure sensor and electromagnetic drop switch ensures automatic unlocking when the ship sinks. The solar panels are designed to be self-sufficient in electricity. The design of power motor, steering gear and navigation piece realizes the self-navigation function of the life buoy, and can change direction flexibly. The design of the sensor module plus the face recognition camera realizes the self-search function. The GSM+GPS module realizes the positioning function and sends the location information to the lifebuoy operating company for help. The wireless transceiver realizes the communication with the remote control, personnel communication, and sends a radio wave distress signal to nearby ships. The display screen can display the position, time, battery information, rescue guidance, and introduction of the structure and function of the life buoy. The remote control can cooperate with rescuers to provide precise guidance, and the operation interface is simple.

Owner:ANHUI UNIV OF SCI & TECH

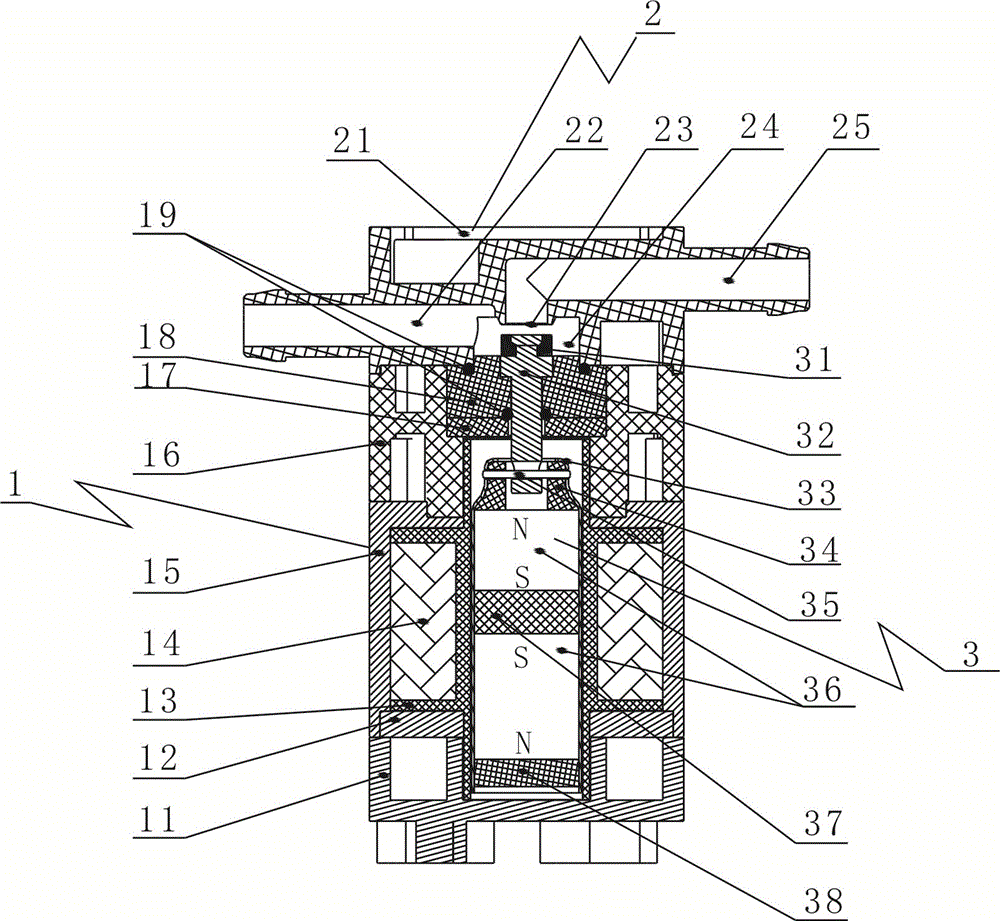

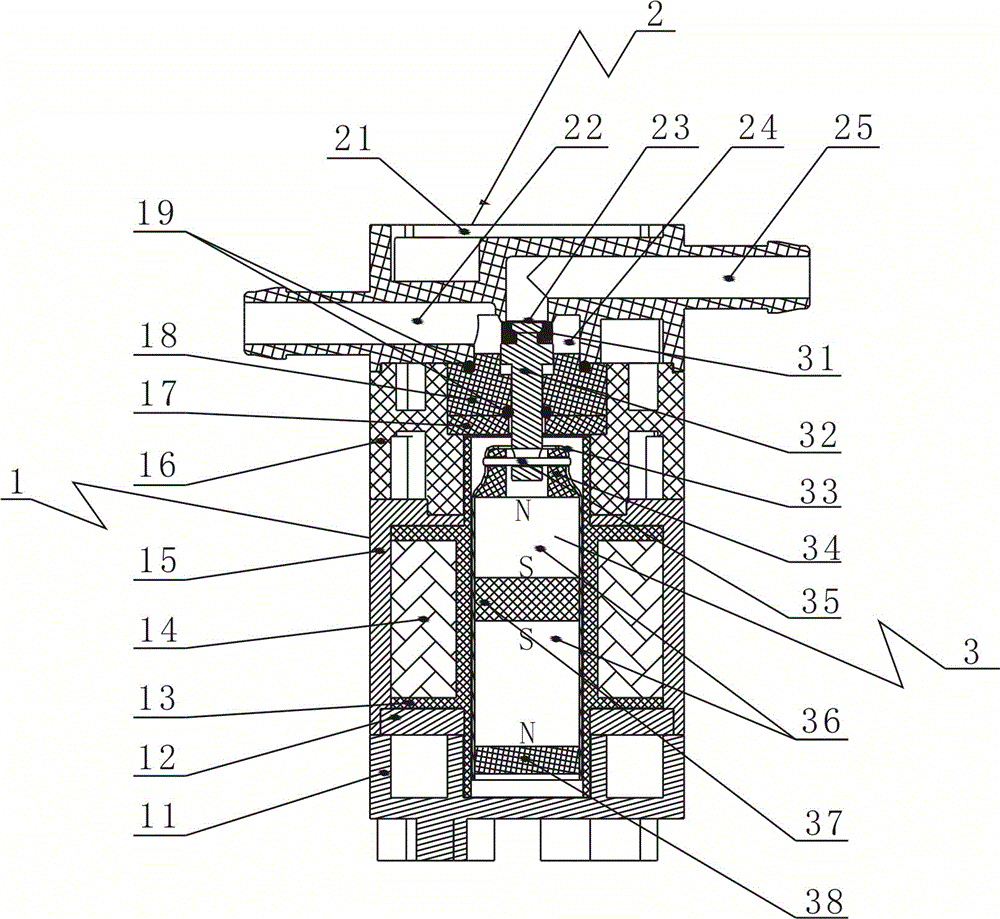

Miniature solenoid valve

InactiveCN104132177AIncrease magnetic fluxEasy to driveOperating means/releasing devices for valvesLift valveInlet channelSolenoid valve

The invention discloses a miniature solenoid valve. The miniature solenoid valve comprises a valve body, a valve deck and a valve pin. The valve deck comprises air channels. The valve pin comprises a sliding sleeve, and a pair of permanent magnets with the poles arranged oppositely are arranged in the sliding sleeve. The drift diameter of the air channels ranges from 2.0 mm to 10.0 mm. The permanent magnets instead of a mechanical spring are adopted in the valve pin, the poles of the permanent magnets are arranged oppositely, the driving force of an electromagnetic switch is greatly increased, the sensitivity to disconnection or connection of the air inlet channel and the air outlet channel by the solenoid valve is higher, and reversing of the electromagnetic switch is more flexible and faster. The drift diameter of the air channels ranges from 2.0 mm to 10.0 mm, and therefore the area of the air channels is enlarged by 25-100 times than that of an existing solenoid valve, and the application range of the miniature solenoid valve is greatly expanded.

Owner:成都气海机电制造有限公司

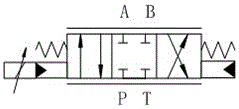

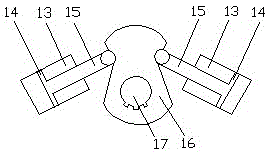

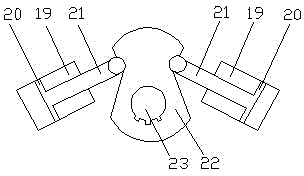

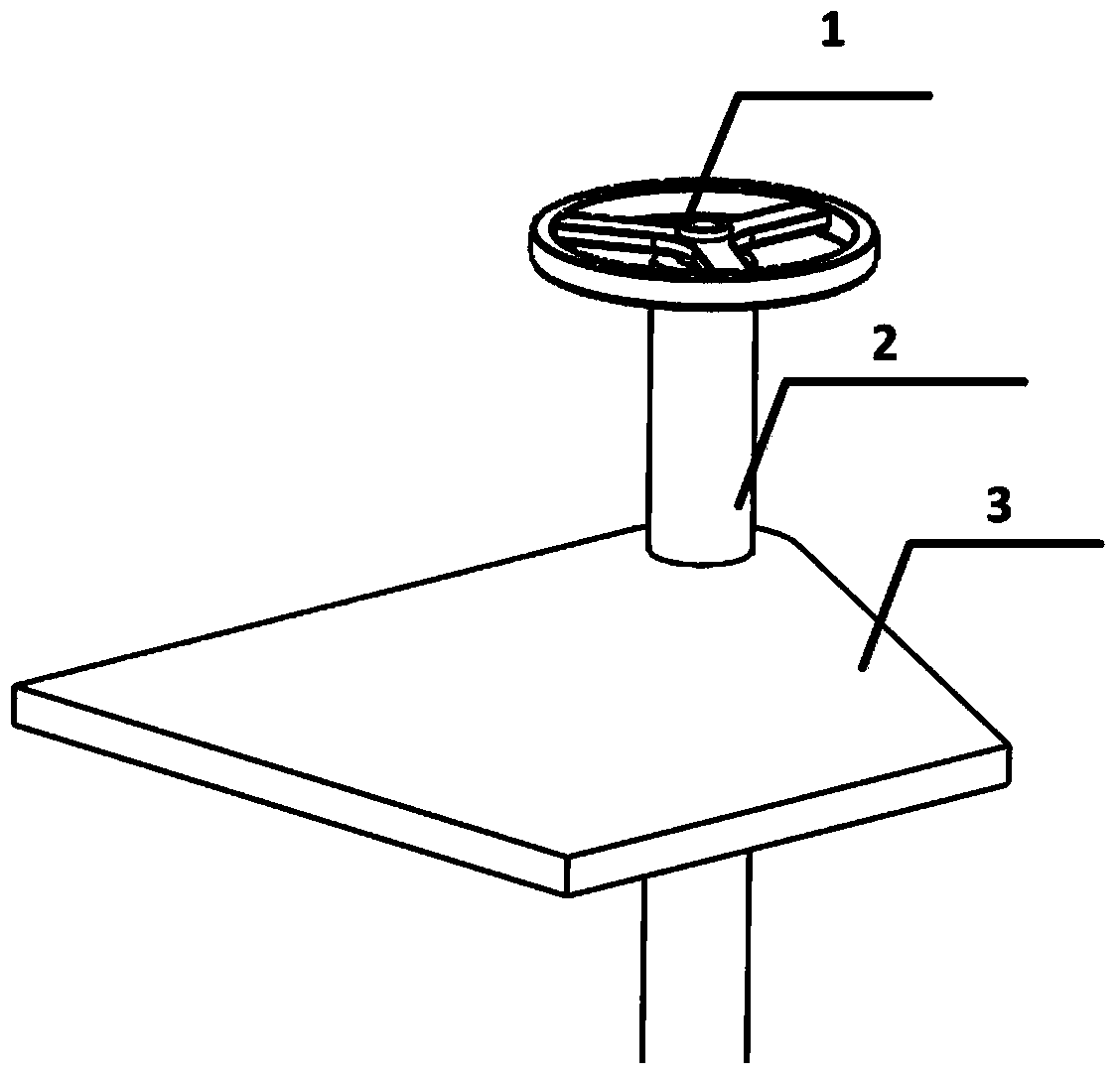

Two-position four-way rotary reversing valve

ActiveCN105736500AReliable designFlexible commutationServomotor componentsEngineeringMechanical engineering

The invention discloses a two-position four-way rotary reversing valve. The two-position four-way rotary reversing valve comprises a valve body, a valve element arranged in the valve body, a valve cover for fixing the valve element in the valve body, and a pressing spring; the valve body includes a baseplate, and a valve element mounting cylinder projected from a mounting surface of the baseplate to be far from the mounting surface; four oil ports P, T, A and B are formed in the baseplate; a large end of the valve element is inserted in the valve element mounting cylinder, and a small end is exposed out of the valve element mounting cylinder; a blocking convex block is arranged on the large end surface of the valve element; the outer diameter of the middle section of the valve element is smaller than the outer diameter of the large end thereof for annularly coating the pressing spring on the middle section; a limiting convex block is outwards projected on the outer wall of the small end of the valve element; the valve cover covers the valve element mounting cylinder for axially fixing the valve element in the valve element mounting cylinder; the valve cover is provided with a through hole for penetrating through the small end of the valve element; and the inner wall of the through hole is outwards projected with an arc limiting space corresponding to the limiting convex block.

Owner:CHONGQING HUAYU HEAVY IND ELECTROMECHANICAL CO LTD

Novel derrick climber

The invention discloses a novel derrick climber, wherein the structure of the climber is composed of a control part, a transmission mechanism, an adsorption device, an adjusting device and a moving device. The working principle of the climber is that the gravity is absorbed on the derrick statically by the suction device, the power source transmits the power to the moving mechanism through the transmission mechanism, and finally the climbing and steering motion is realized. The control part coordinates the suction device and the moving mechanism, and the adjusting device is used to keep the crawling arm parallel to the crawling surface. The invention discards the mechanical clamping device which is complex and large in size, and simplifies the whole structure of the climber. The climber can climb on the main leg of the derrick by means of electric motor and program control, climb up the derrick to complete the detection work by the route set by a certain speed delay, and has certain flexibility to realize the steering from the main leg to the truss, and can be well adapted to the uneven crawling surface.

Owner:SOUTHWEST PETROLEUM UNIV

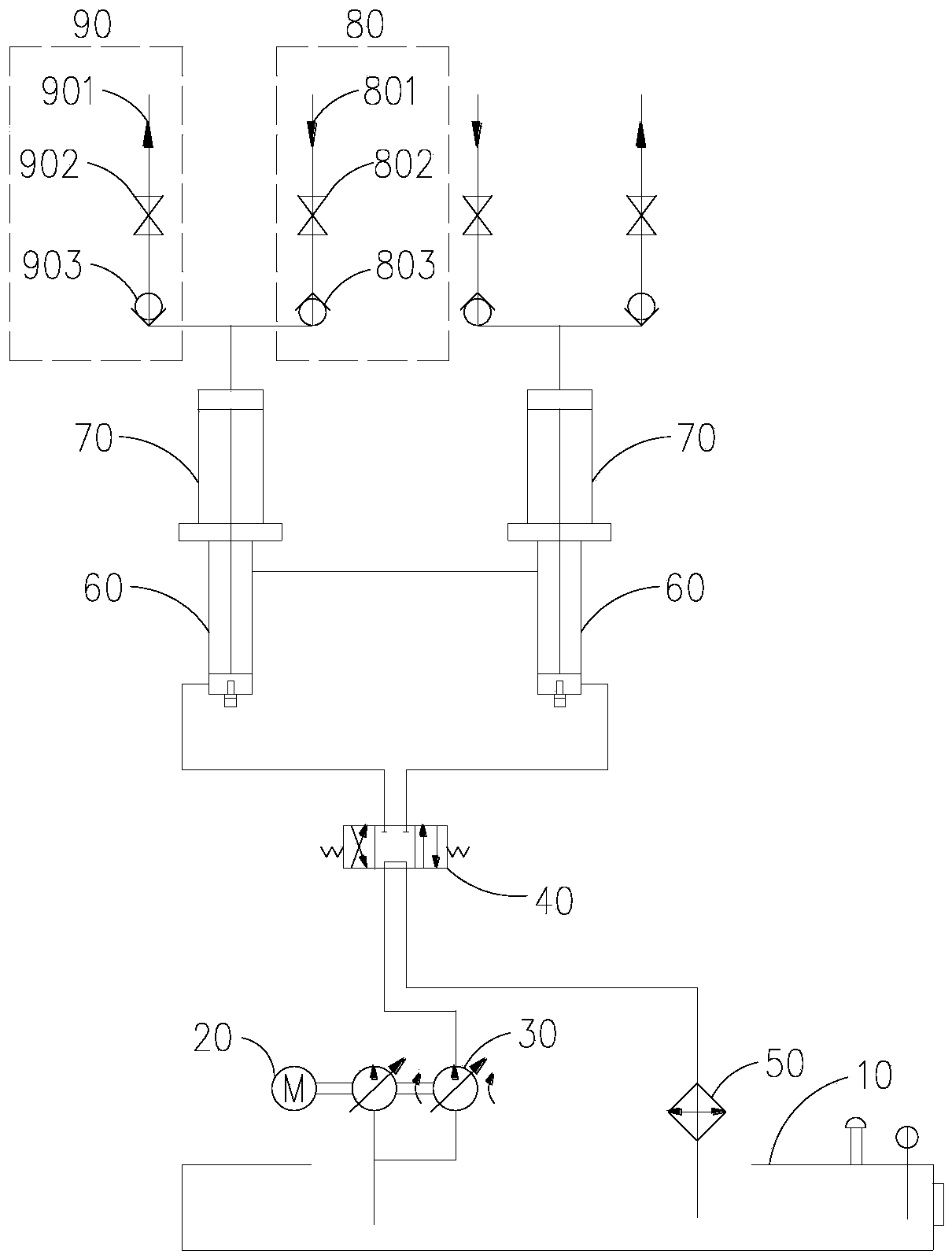

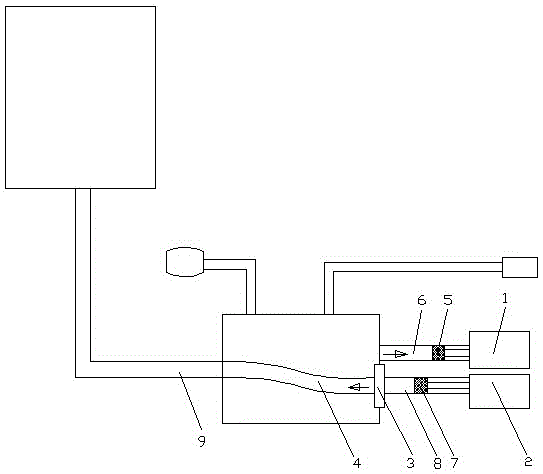

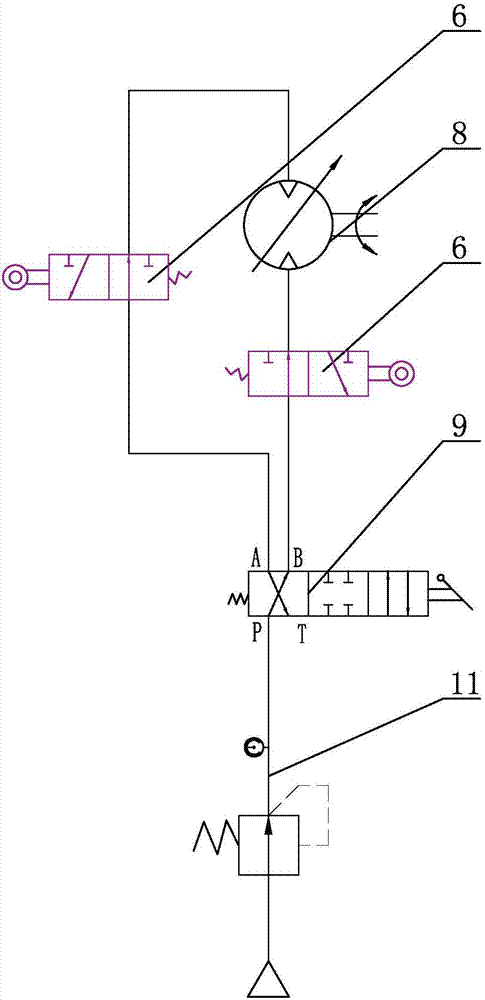

High-pressure slurry conveying pump system and method

InactiveCN108953089AImprove efficiencyImprove pumping efficiencyPositive displacement pump componentsPump controlReciprocating motionFuel tank

The invention relates to fluid pumping equipment, in particular to a high-pressure slurry conveying pump system and method. The high-pressure slurry conveying pump system comprises a power system anda hydraulic system. The power system comprises a hydraulic oil tank, a main motor, a main oil pump, a hydraulic reversing valve, a cooler and main oil cylinders. The hydraulic system comprises conveying cylinders, a feeding subsystem and a discharging subsystem. The high-pressure slurry conveying method comprises the steps that firstly, the hydraulic oil tank, the main motor and the main oil pumpcontrol pistons in the main oil cylinders to do reciprocating motion through switching of the hydraulic reversing valve; secondly, the pistons in the main oil cylinders drive pistons in the conveyingcylinders to do reciprocating motion; and thirdly, when the pistons in the conveying cylinders move backwards, a feeding conic valve is opened, a discharging conic valve is closed, slurry is sucked infrom a feeding pipe, when the pistons in the conveying cylinders are pushed forwards, the feeding conic valve is closed, the discharging conic valve is opened, and the slurry is discharged from a discharging pipe. The high-pressure slurry conveying pump system and method have the advantages of being high in conveying efficiency, safe and reliable to use, simple in structure and flexible in mounting.

Owner:日昌升集团有限公司

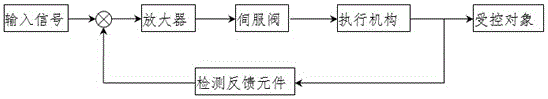

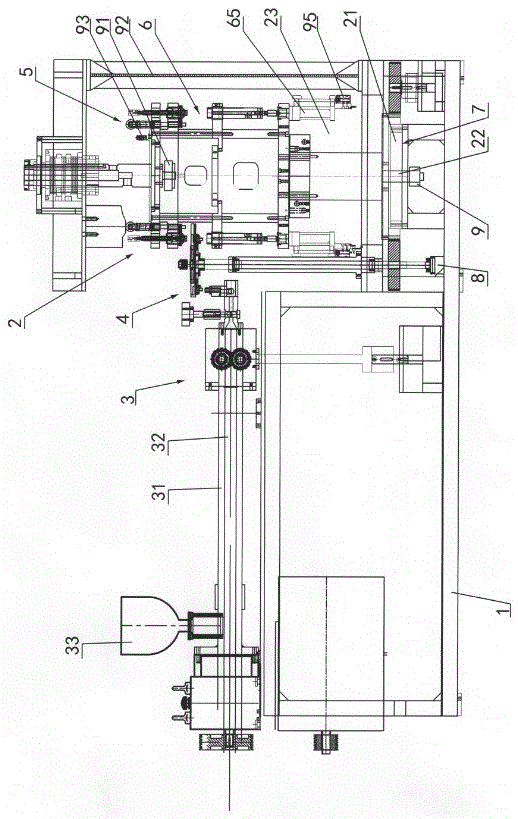

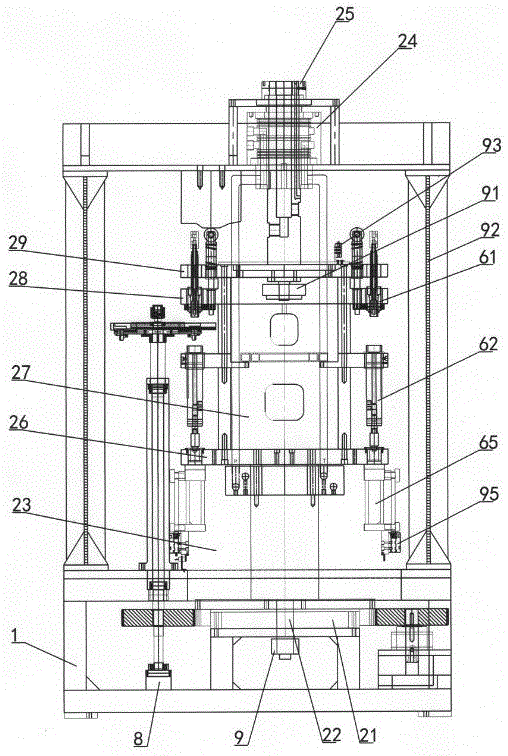

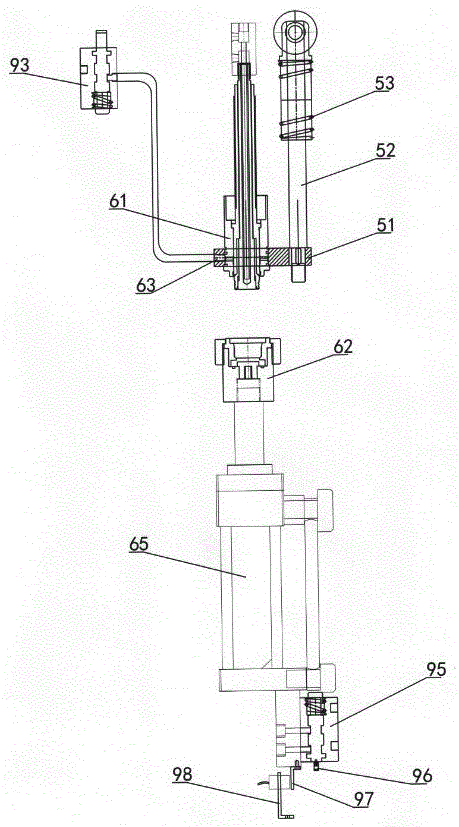

Servo hydraulic type bottle cap compression molding machine

ActiveCN105538736AHigh speedReduce lossesDomestic articlesCompression moldingHuman–machine interface

A servo hydraulic type bottle cap compression molding machine comprises a main machine assembly, an extrusion mechanism, a feeding mechanism, a cap discharging mechanism, a die part and a transmission mechanism, all of which are arranged on a rack. The transmission mechanism is driven by a motor. The main machine assembly comprises a heavy load bearing arranged in the rack. The lower portion of the heavy load bearing is connected with a main shaft. The main shaft is connected with the transmission mechanism and provided with a precise electric conduction slip ring. One end of the precise electric conduction slip ring is connected with a rotary encoder connected with a human-computer interface. The human-computer interface is connected with an electric control valve connected with a die stripping and air blowing valve. A proportional servo hydraulic valve is arranged below a gland oil cylinder and provided with a pressure sensor. The pressure sensor is connected with a displacement induction piece connected with a displacement sensor. The displacement sensor is connected with the other end of the precise electric conduction slip ring. According to the scheme, the electric conduction slip ring is adopted for electric conduction, air blowing and die stripping are controlled through a servo hydraulic gland and the electric control valve, control is accurate, and the speed and the production efficiency are high.

Owner:TAIZHOU HUANGYAN YIJING PLASTIC & MOLD

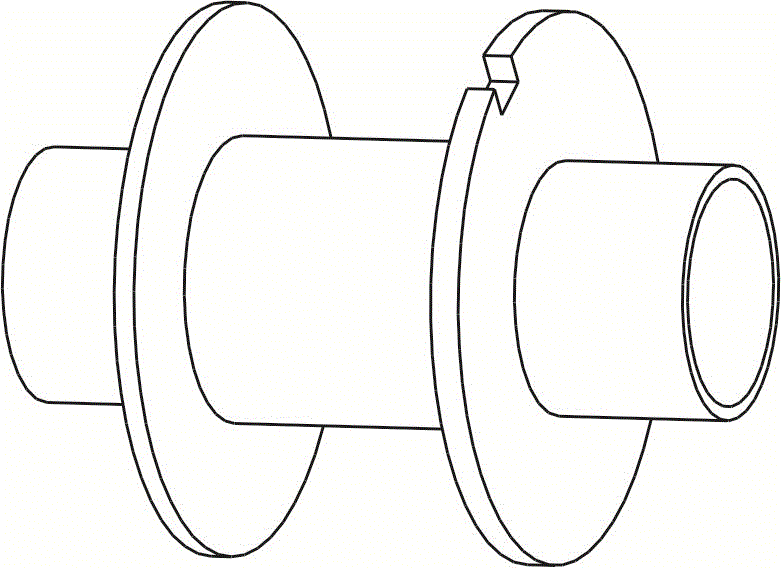

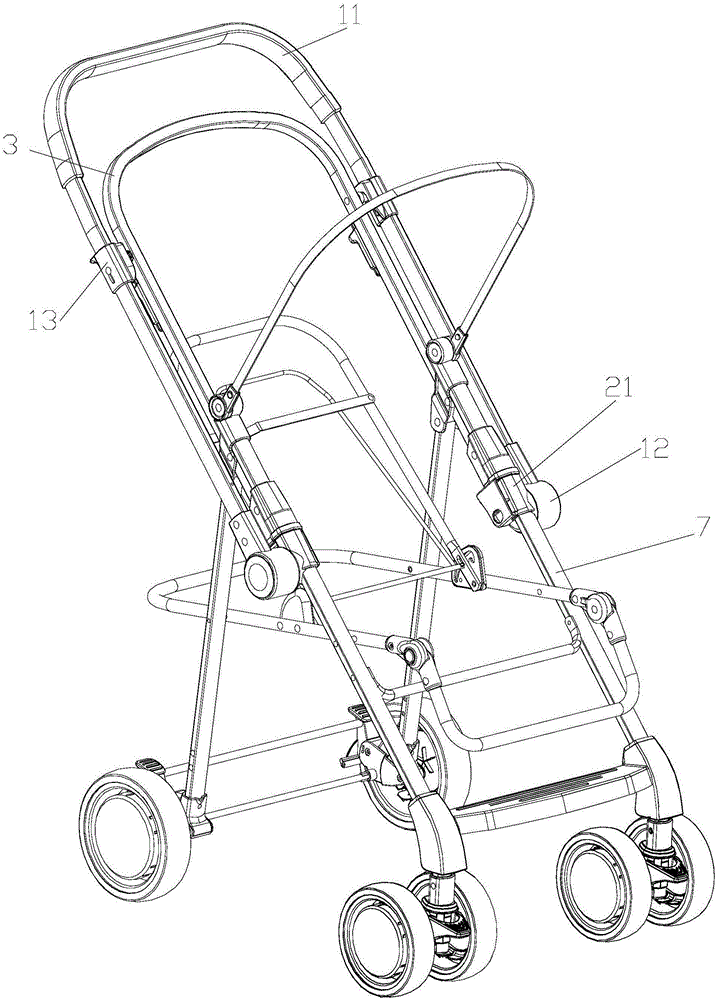

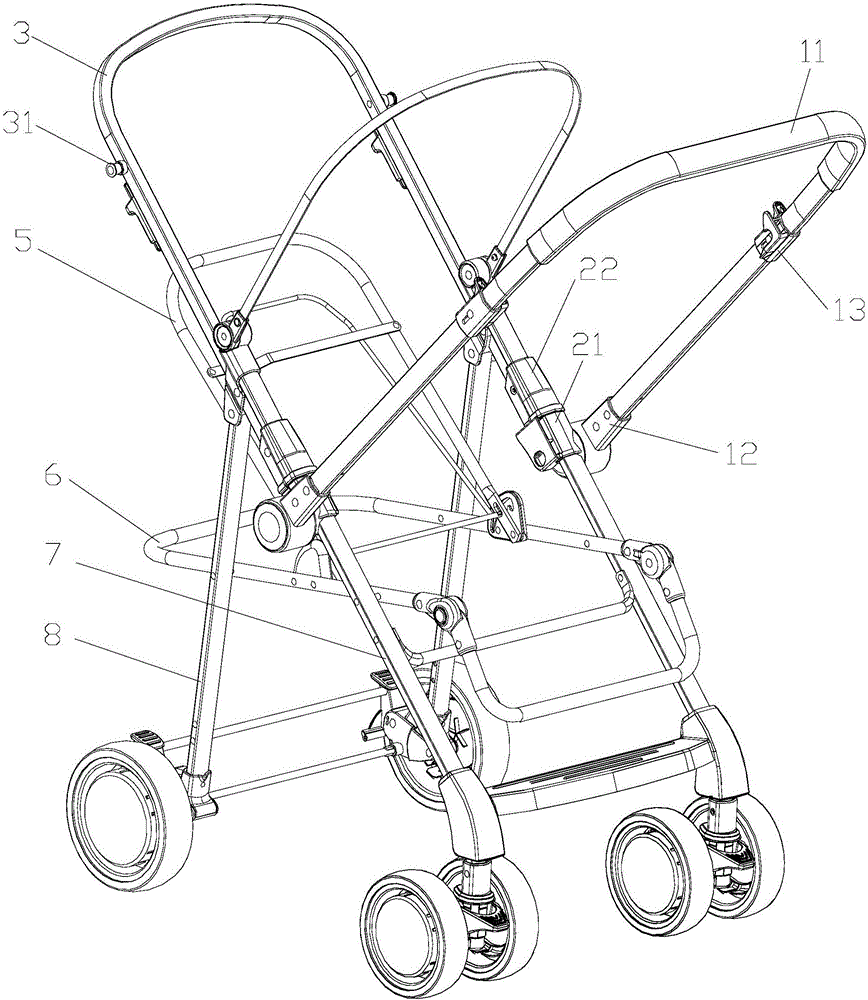

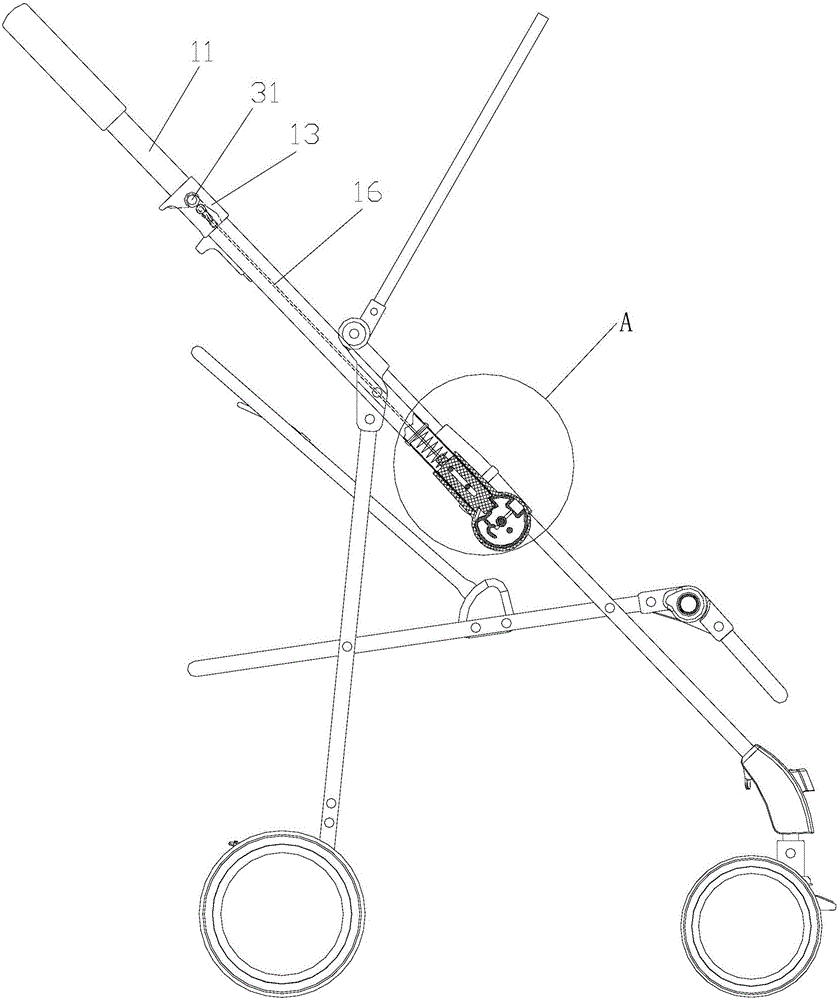

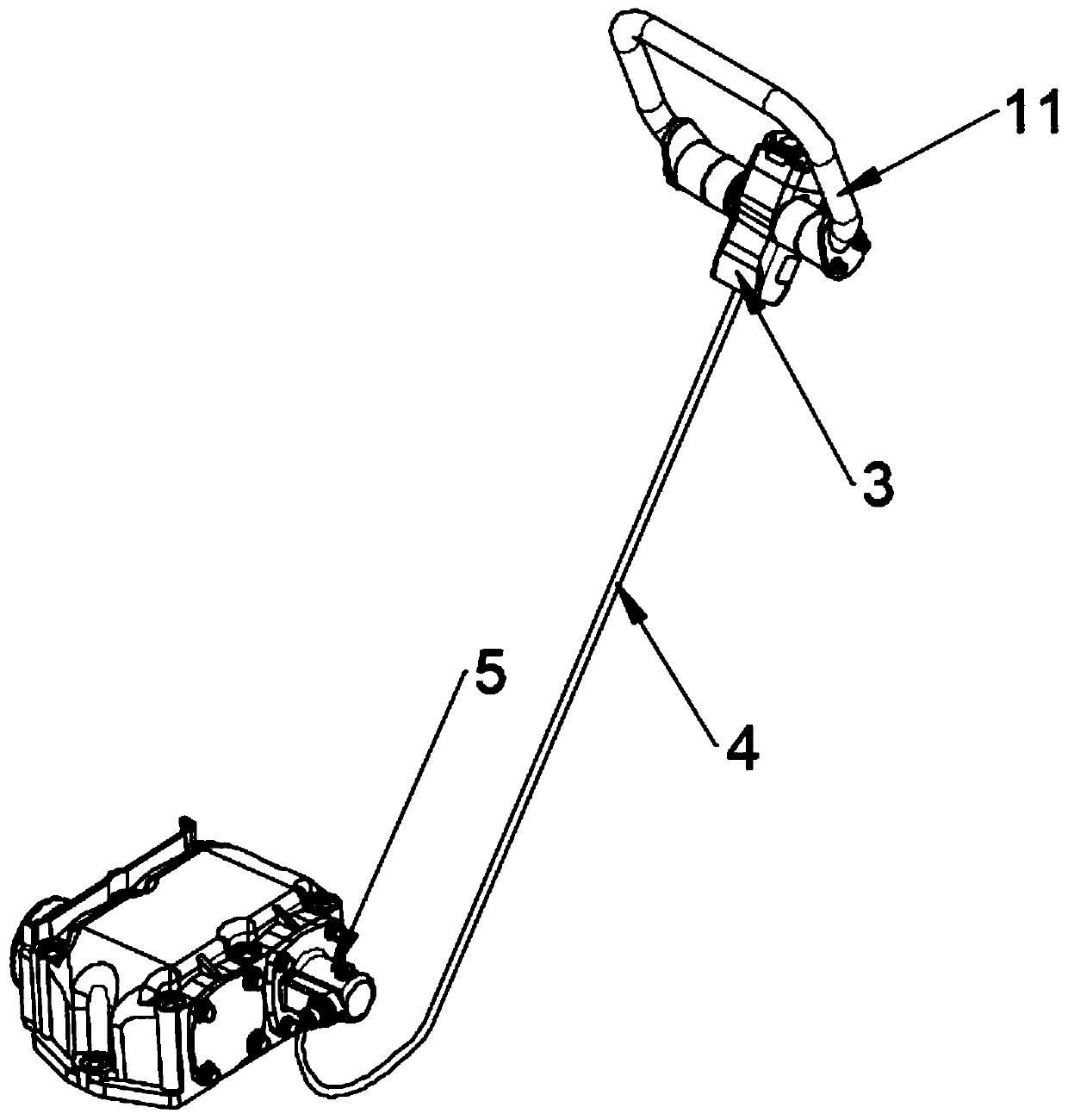

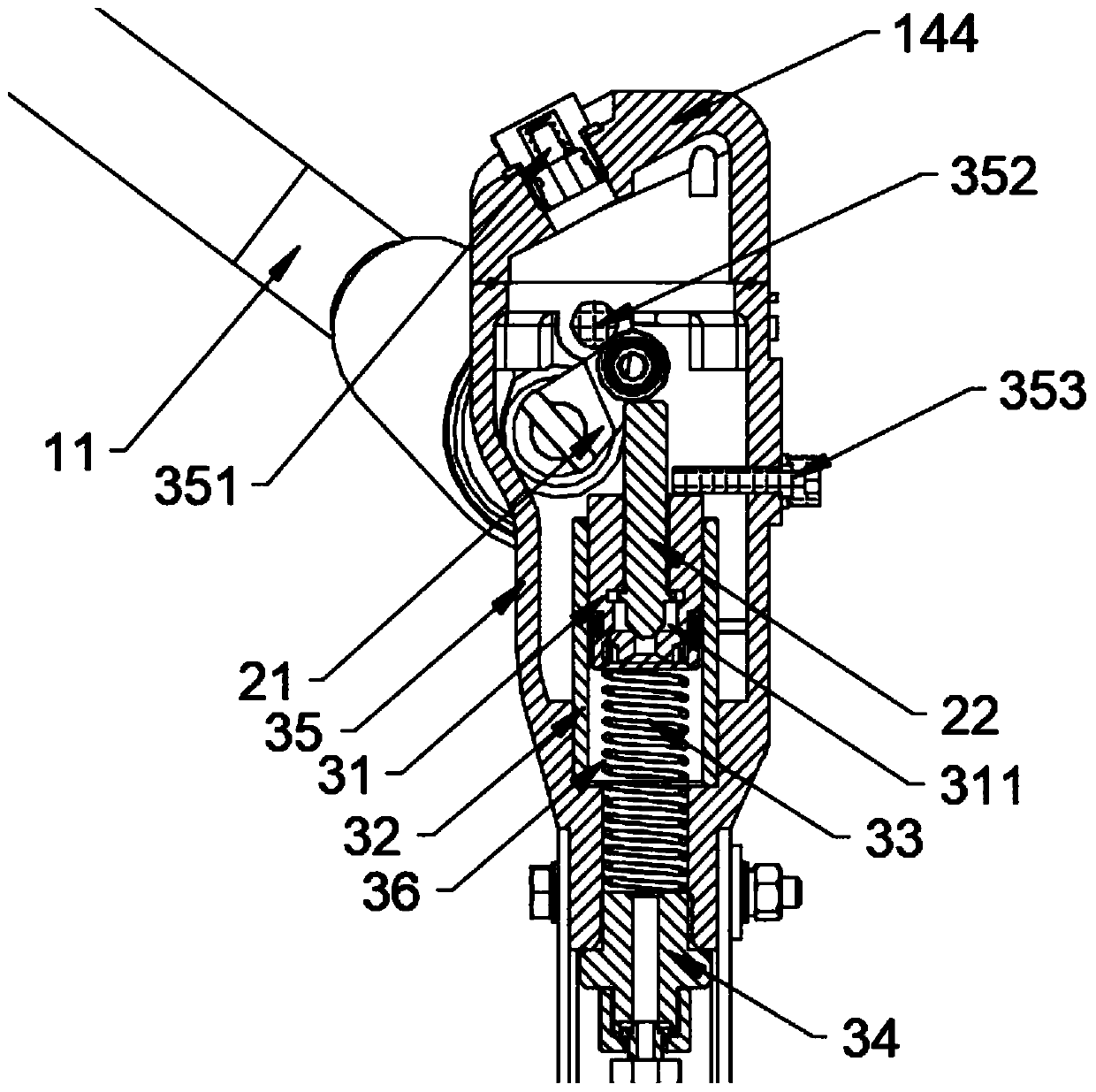

Baby stroller with reversible push handle lever

PendingCN106828581AFlexible commutationCarriage/perambulator accessoriesEngineeringElectrical and Electronics engineering

The invention discloses a baby stroller with a reversible push handle lever. The baby stroller comprises an upper connection rod, front legs and a handle lever, wherein front leg supporting pipes and handle lever supporting pipes are connected through push handle reversing devices; the push handle reversing devices comprise handle seats and lower joints; the handle seats are fixed at the end parts of the handle lever supporting pipes; the lower joints are fixed at the middle parts of the front legs; first cylindrical sleeves are laterally arranged on the lower joints; a second cylindrical sleeve with a sleeve bottom is arranged at one end of each handle seat; the second cylindrical sleeves are oppositely connected outside the first cylindrical sleeves in a sleeving manner; first limiting parts are arranged inside the first cylindrical sleeves; limiting pins are fixed at the sleeve bottoms of the second cylindrical sleeves; first locating slots and second locating slots are formed in the outer surfaces of the first cylindrical sleeves; locating lock pins capable of sliding up and down are arranged in the handle lever supporting pipes; the first locating slots and the second locating slots are matched with the end parts of the locating lock pins; when the locating lock pins are clamped with the first locating slots and the second locating slots respectively, the first limiting parts and the limiting pins are respectively in separated and combined states.

Owner:NINGBO SHENMA GROUP

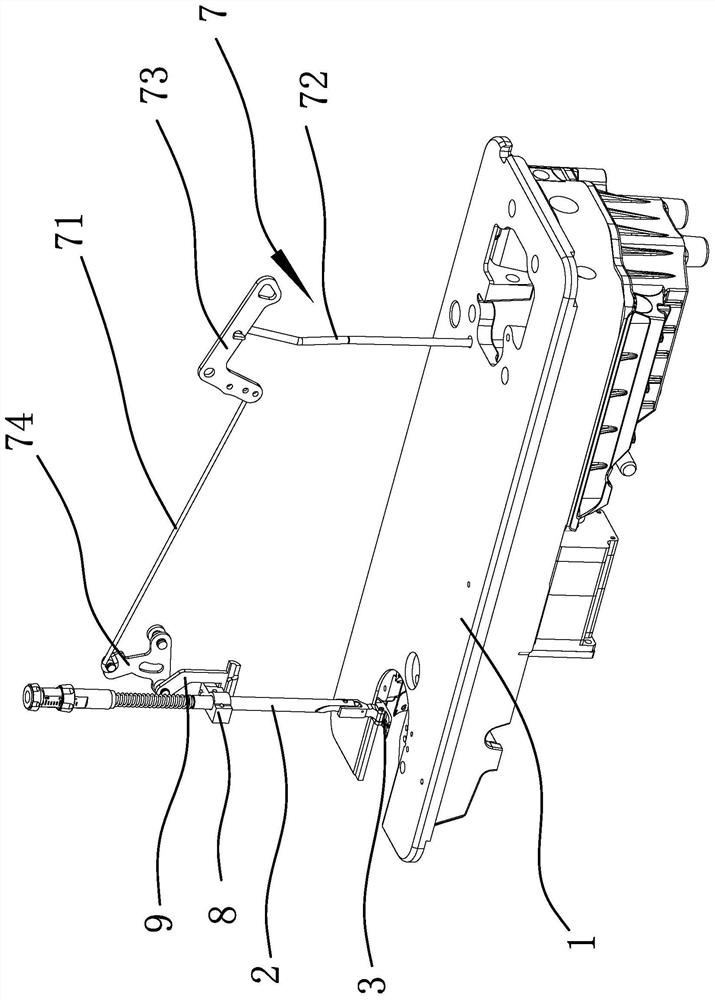

Bidirectional single-furrow plough

InactiveCN101449640AReasonable structureLow costAgricultural machinesPloughsAgricultural engineeringTractor

The invention relates to a bidirectional single plow, comprising a plow bottom, a plow base, a plow body frame, a plow standard, a front tractor seat and a rear tractor seat, a draft sill and a tilling width and depth regulating device and a plow bottom turnover unit, wherein the tilling width regulating device is composed of a location piece in the draft sill location seat and a location plate on the front tractor seat; the depth regulating device is composed of nuts hinged in a lead screw bearing and a pin for adjusting the lead screw hinged in a depth regulating seat; the plow bottom turnover unit is composed of a transmission shaft equipped with the plow body frame in a plow base shaft hole; a reversing shaft is hinged on the depth regulating seat, and a reversing sleeve sleeved on the reversing shaft is fixed on the plow standard, a plow standard location former is arranged on the transmission shaft, a lower pin of a control rod is matched with a hole on the plow standard location former, an upper lower pin is matched with a groove on the plow standard location former, thereby realizing location of overturn of the plow bottom and deflexion of the plow standard. According to the invention, operation is convenient, reversing is smart, the plow bottom and the plow standard are tiltable, plow pair adjustment is precise, adaptability is strong.

Owner:陈锡顺

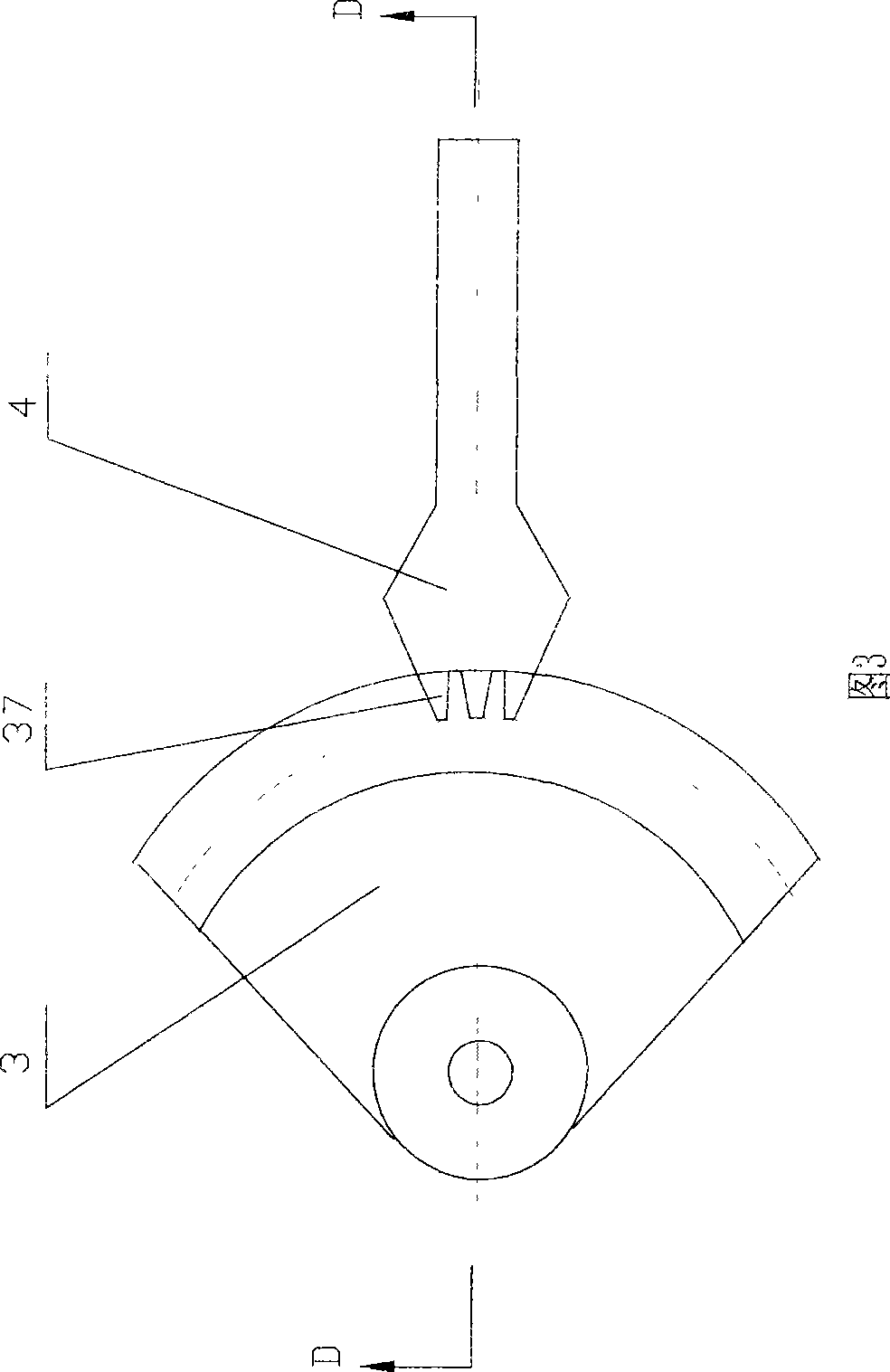

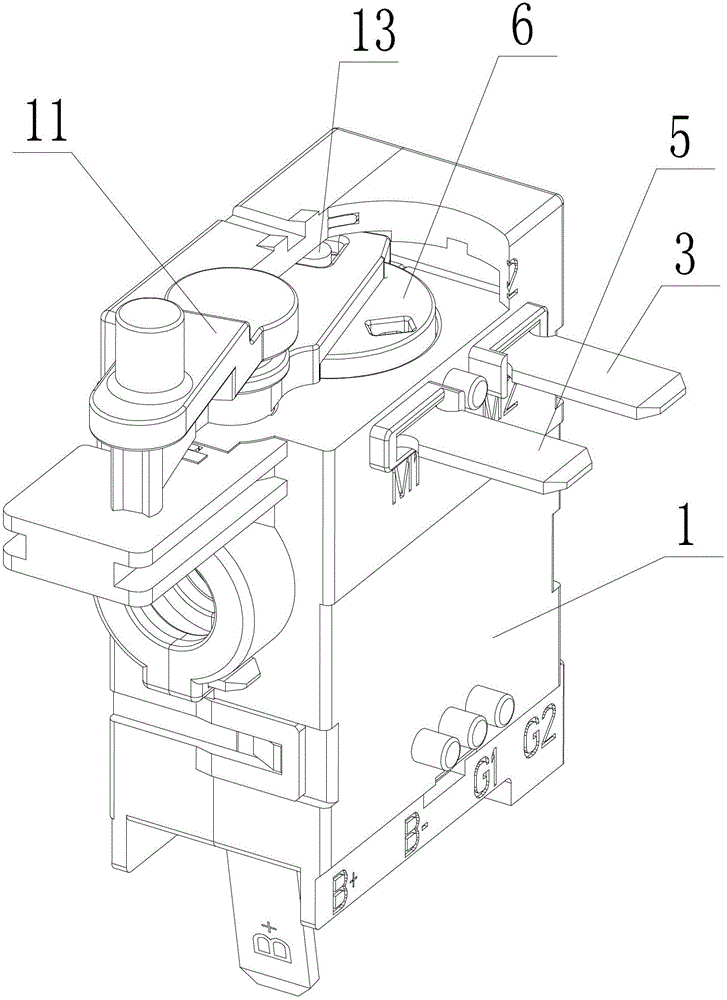

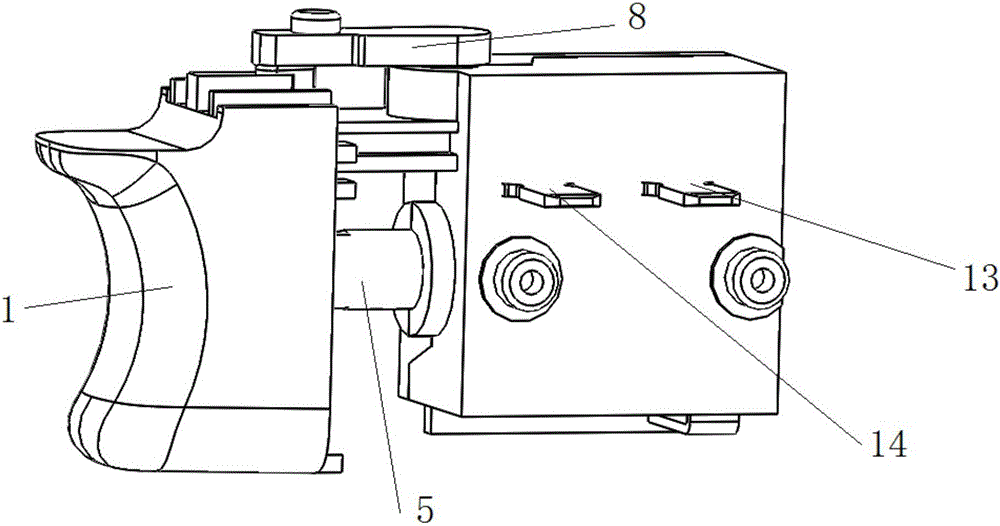

Switch reversing device in electric tool

InactiveCN102723217AThe overall structure is compactFlexible commutationContact electric connectionPower tool

Owner:ZHANGJIAGANG HUAJIE ELECTRONICS

Particle drilling method

InactiveCN105134080ASimplify the screening processImproving the efficiency of percussion drilling operationsDrilling machines and methodsWell drillingParticle injection

Owner:CCDC PETROLEUM CORING TECH

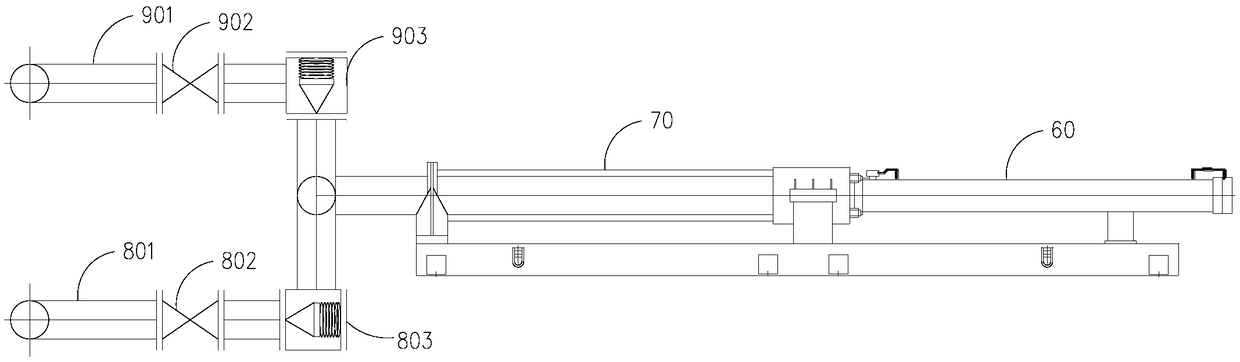

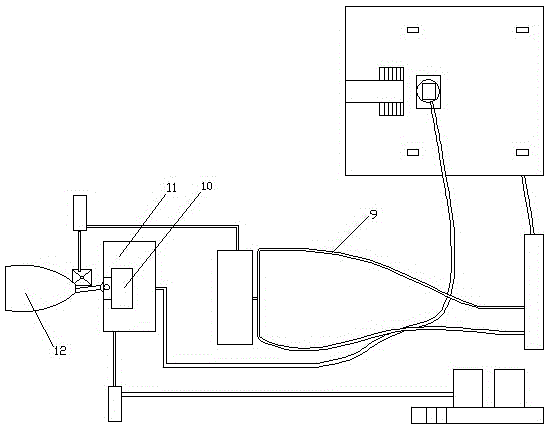

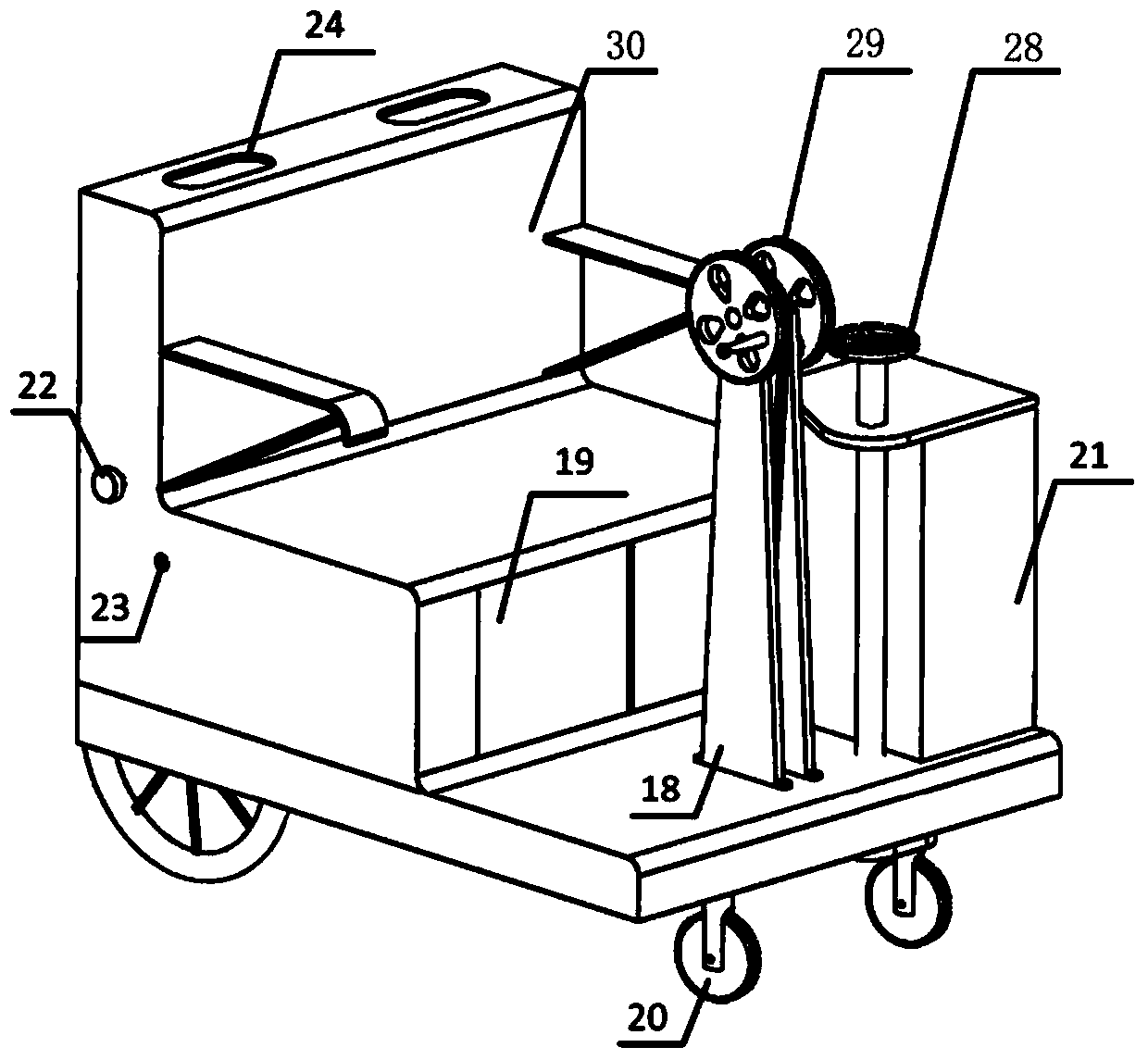

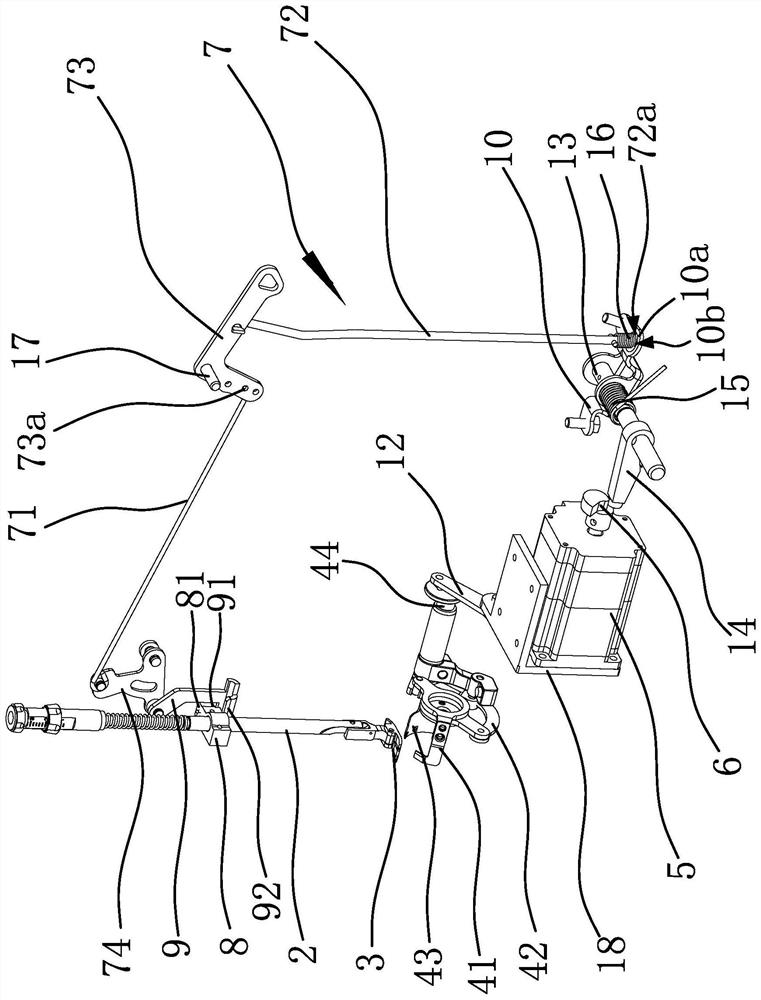

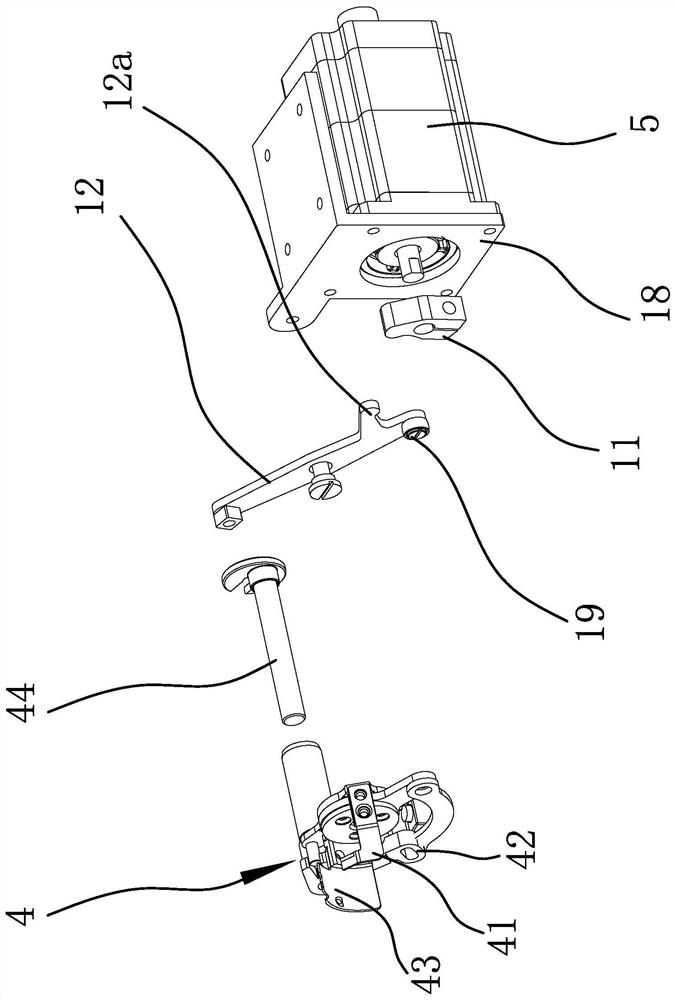

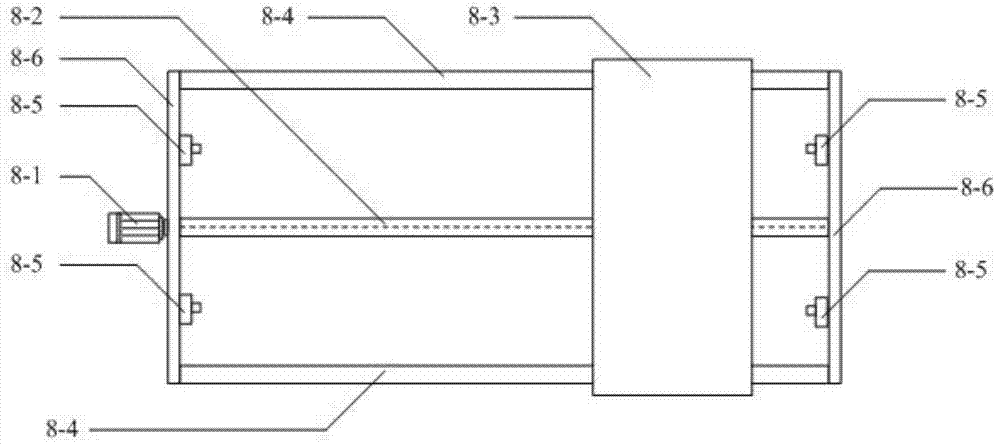

Double-injection pump continuous injection device applicable to particle well drilling

InactiveCN104963631AGuaranteed continuityPrevent sediment cloggingConstructionsLiquid/gas jet drillingHydraulic cylinderWell drilling

The invention discloses a double-injection pump continuous injection device applicable to particle well drilling, and belongs to the technical field of oil-gas drilling engineering. The double-injection pump continuous injection device comprises a particle mixing hopper. A reversing pipe is arranged inside the particle mixing hopper. A swing hydraulic cylinder is connected to the reversing pipe. A first conveying cylinder and a second conveying cylinder are connected to the particle mixing hopper. A first piston is arranged inside the first conveying cylinder. A second piston is arranged inside the second conveying cylinder. The first piston is connected to the first hydraulic cylinder through a first piston rod. The second piston is connected to the second hydraulic cylinder through a second piston rod. One end of the reversing pipe is communicated with a high-pressure pipeline, and the other end of the reversing pipe is communicated with the first conveying cylinder or the second conveying cylinder. A slurry pump is communicated with the particle mixing hopper through a first pipeline. A screw conveyor is communicated with the particle hopper through a second pipeline. According to the double-injection pump continuous injection device, injection continuity of particles into a well can be ensured, the working efficiency of particle impact drilling is effectively improved, the high-pressure area coverage range is small, and safety risk is lowered.

Owner:CCDC PETROLEUM CORING TECH

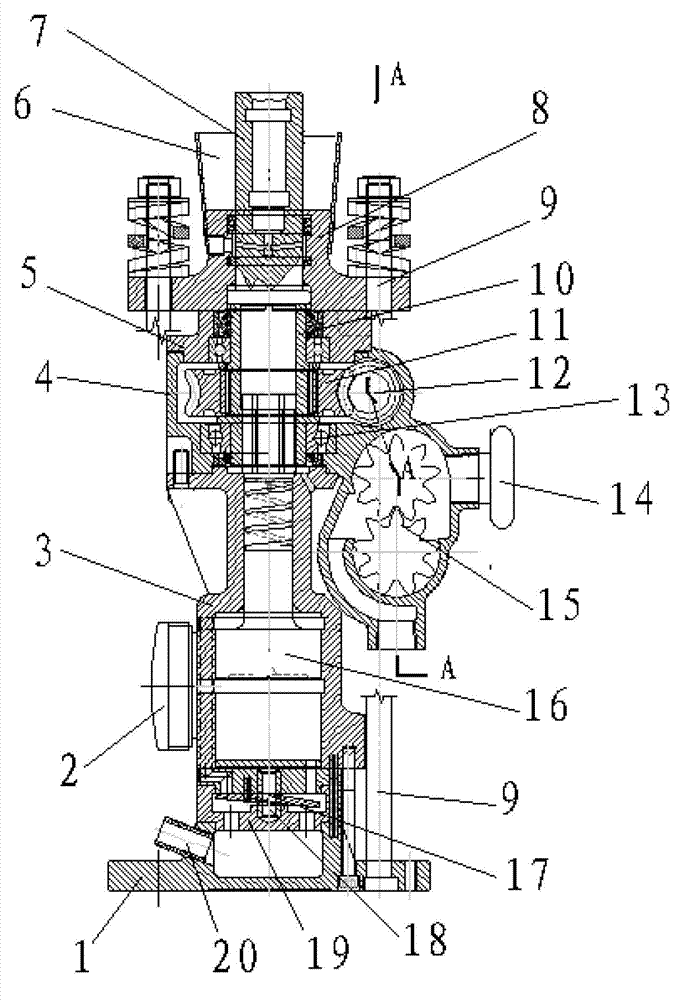

Quick-drill pneumatic hard rock drill

ActiveCN102900355AHigh shear forceIncrease propulsionConstructionsReciprocating drilling machinesAtmospheric pressureCylinder block

The invention discloses a quick-drill pneumatic hard rock drill which comprises a host machine, an operating valve and a propulsion unit, which are independent of one another and are connected with one another. An air suction nozzle communicated with an air distribution valve is arranged on a base of the host machine; the air distribution valve is in a fin type structure and consists of a valve body, a valve block and a valve rod; a valve cavity is arranged inside the valve body and is respectively communicated with a front chamber and a back chamber of a cylinder body through left and right air passages; the seesaw-like valve block is installed in the valve cavity through the valve rod; under the action of air pressure, the two ends of the valve block can respectively close or open the left and right air passages to enable a piston rod to move with high frequency; and a rotating device is arranged on a machine head. According to the invention, a new fin type air distribution valve which is flexible in change-over is adopted, so the impact frequency is greatly improved. The rotating device realizes primary transmission by adopting worm-and-gear principle, the transmission ratio is big, and the transmission efficiency is high. The quick-drill pneumatic hard rock drill is small in size, light in weight and convenient to operate, and is applicable for various propulsion modes.

Owner:青岛达邦钻机有限责任公司

Elactro magnetic commutator

InactiveCN1624363ASolve the difficulty of reversingCompact structureGearing controlEngineeringRotation around a fixed axis

A electromagnetism commutator., which involves the combining of the axis. It includes the cover, the transferring axis and the electromagnet, the two-sides grating pieces which contains the cover of the commutator. The in and out transferring axis is connected with the active gear and the passive gear. When it galvanizes, the transferring-in axis will run synchronically. Or it will work contrarily.

Owner:DALIAN UNIV

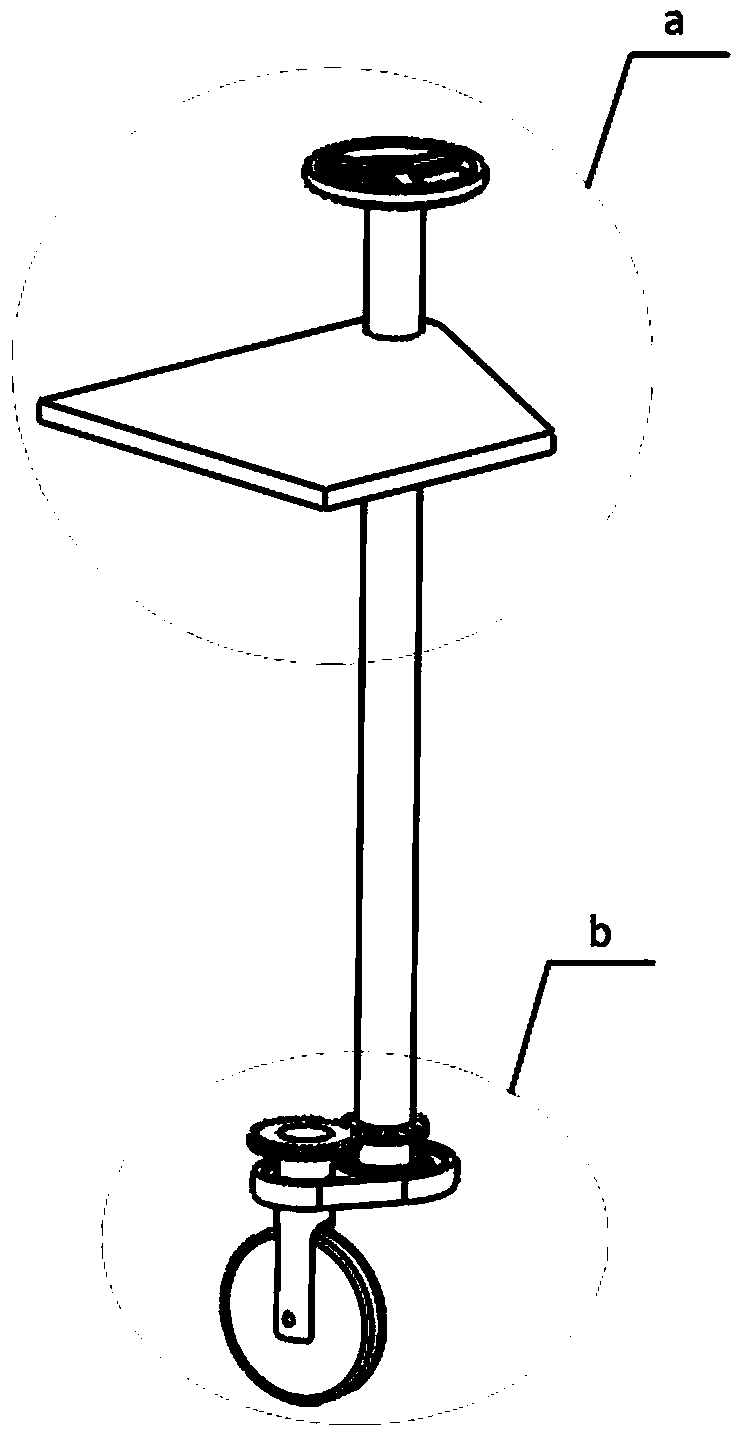

Manual four-wheel multifunctional vehicle special for old persons

ActiveCN103720549ASolve the difficult problem of getting on and off the walkerChange the problem of inconvenient up and downWheelchairs/patient conveyanceSmall amplitudeOlder people

The invention relates to scooters, in particular to a manual four-wheel multifunctional vehicle special for old persons. An article table (3) is arranged on a reversing mechanism (28). A reversing steering plate (1) drives a driving post (2) to drive a large transmission gear (41) driving a small transmission gear (42) so as to drive a steering wheel (8) to rotate. The seat is a rotatable seat (30) rotating through the steering plate. The manual four-wheel multifunctional vehicle has the advantages that the problem that an old person finds difficult to get on and off a vehicle can be solved; the reserving mechanism can be operated conveniently and simply by one hand, and steering is flexible and can be performed through small amplitude only; the article table provides the position for a user to place commonly-used articles, fatigue of the user can be alleviated in the process of arm suspending during steering, and stability in the rotating process can be improved; the effect of exercising arms can be achieved by driving a handle in a swinging manner; the angle of the backrest of the rotatable seat can be adjusted according to usage.

Owner:杭州银江智慧健康集团有限公司

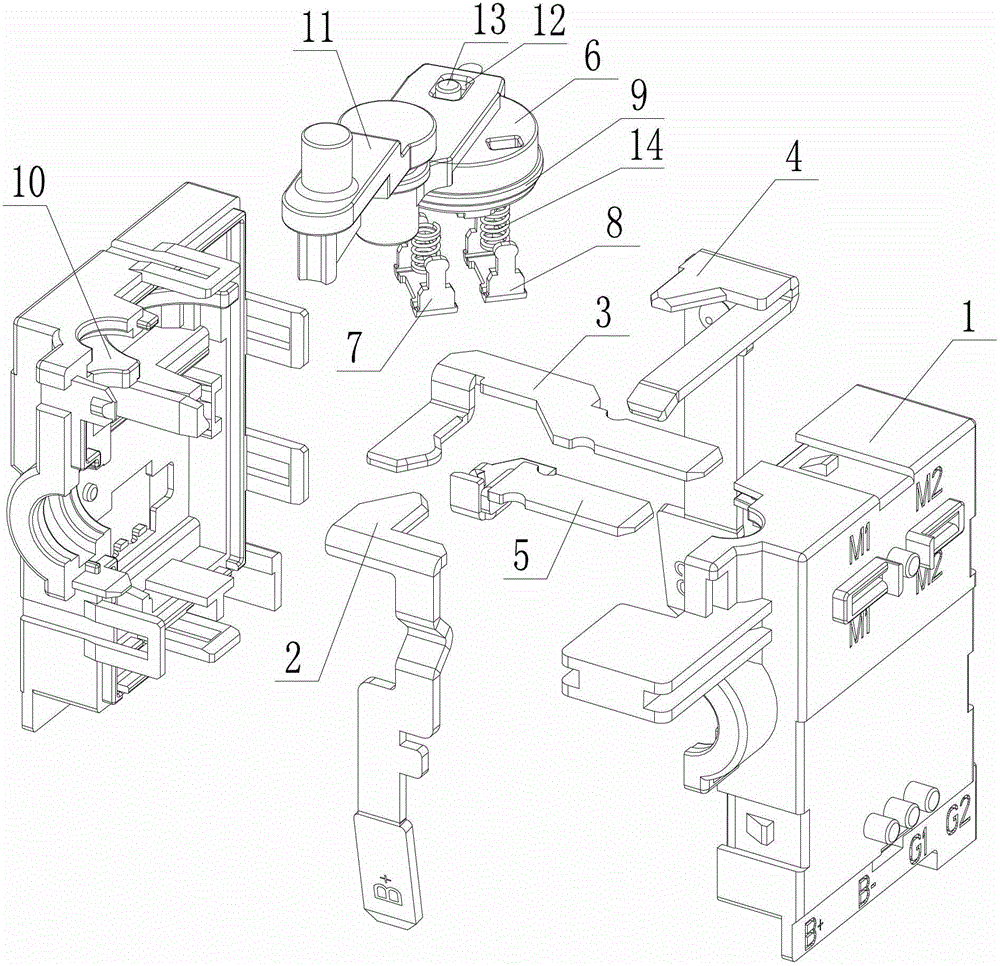

Reversing switch of electric tool

ActiveCN106409552AImprove reliabilityEasy to assembleElectric switchesMechanical engineeringEngineering

The invention discloses a reversing switch of an electric tool. The reversing switch comprises a button, a base, an inner base, a push rod, a reversing base and a reversing shift handle, wherein the push rod is connected with the button; the reversing base is arranged above the inner base; the reversing handle is arranged above the reversing base; a first terminal of which one end extends out of the base and a second terminal of which one end extends out of the base are arranged in the reversing base; one end part of the first terminal is positioned between two end parts of the second terminal; the first terminal, the second terminal and the reversing base are integrated; one end part of a third terminal and one end part of a fourth terminal are arranged on the base respectively; the other end part of the third terminal and the other end part of the fourth terminal pass through a positioning groove and extend onto the reversing base; the end parts extending onto the reversing base are on the same plane as end parts of the first terminal and the second terminal in the reversing base; a V-shaped movable contact spring is hinged to the fourth terminal; a power supply terminal corresponding to the V-shaped movable contact spring is arranged in the base; a positioning plate is arranged above the reversing base; and a limiting device which is connected with the reversing shift handle is arranged above the positioning plate. The switch is easy to assemble, low in cost and accurate in reversing, has high reliability, and can be switched on automatically.

Owner:ZHANGJIAGANG HUAJIE ELECTRONICS

A combination combination lock

ActiveCN106121388BImprove securityAvoid safety hazardsElectric permutation locksLatching locksStructural engineeringClutch

Owner:徐州宇之阳市场营销策划有限公司

Four-axis device of wire drawing machine

The invention relates to a four-axis device of a wire drawing machine, which comprises a four-axis main axis. The four-axis device is characterized in that a bearing seat is arranged on the four-axis main axis, one end of the bearing seat is connected with an upper cover of the bearing seat and the other end of the bearing seat is connected with a lower cover of the bearing seat; an upper bearing steel ring and a first frame oil seal are arranged in the upper cover of the bearing seat surrounding the four-axis main axis and a first double-column roller spherical bearings are arranged between the upper cover of the bearing seat and the bearing seat; a lower bearing steel ring is arranged in the lower cover of the bearing seat surrounding the four-axis main axis; an oil deflector and a second double-column roller spherical bearings are installed between the bearing seat and the lower cover of the bearing seat surrounding the four-axis main axis; a first round flat key is arranged in a key way of the first end of the four-axis main axis and a circular arc synchronous belt pulley is sleeved at the first end of the four-axis main axis; and a second round flat key is arranged in a key way of the second end of the four-axis main axis and a four-axis step pulley group is sleeved at the second end of the four-axis main axis. The invention has simple, compact and reasonable structure and convenient assembling and disassembling, and can stabilize the drawing process, change directions flexibly and improve work efficiency.

Owner:WUXI PINGSHENG SCI & TECH

Pneumatic yarn winding and guiding device

The invention provides a pneumatic yarn winding and guiding device and belongs to the technical field of textile machines. The pneumatic yarn winding and guiding device comprises a yarn guiding seat, a swing arm, a yarn guiding device, a guide block and a swing air cylinder. The swing air cylinder is arranged in the yarn guiding seat. The guide block is fixedly arranged on the front side face of the yarn guiding seat and provided with a vertically-through transverse sliding groove. The lower end of the swing arm is connected with a swing shaft of the swing air cylinder. The upper end of the swing arm penetrates the transverse sliding groove. The yarn guiding device is arranged at the upper end of the swing arm. The swing air cylinder drives the swing shaft to swing in a reciprocating manner so as to drive the yarn guiding device at the upper end of the swing arm to conduct reciprocating motion along an arc track. The chord direction of the arc track is the same as the direction of a bobbin shaft installed on a supporting bobbin. By the adoption of the pneumatic yarn winding and guiding device, yarn guiding efficiency is improved, and the yarn bobbin forming effect is good.

Owner:ZHEJIANG RIFA TEXTILE MACHINERY TECH CO LTD

Fabric gluing device

ActiveCN105903643ARealize shuntQuick resetLiquid surface applicatorsCoatingsEngineeringAtmospheric pressure

The invention provides a fabric gluing device, and belongs to the technical field of machining. The fabric gluing device comprises a glue pipe, a coating head, a bearing frame, a gluing tongue and a pneumatic system; a piston rod of a first cylinder is hinged to the lower end of the glue pipe; a long hole is formed in the middle end of the glue pipe; a piston rod of a second cylinder is hinged to the long hole in the middle end of the glue pipe; the coating head is mounted at the upper end of the glue pipe; the bearing frame is fixedly arranged in the coating head; glue grooves are equally formed in the periphery of the bearing frame; the gluing tongue is mounted in the coating head, and extends out of a head opening by a period of length; a spring is arranged between the gluing tongue and the bearing frame; a first valve port and a second valve port are connected with a first reversing valve; a third valve port and a fourth valve port are connected with a second reversing valve; the first reversing valve and the second reversing valve are both connected with one end of a pressure reducing valve; the other end of the pressure reducing valve is connected with one end of a one-way throttle valve; and the other end of the one-way throttle valve is connected with an air source. The fabric gluing device once realizes interval gluing of four narrow fabrics, and greatly improves the gluing efficiency.

Owner:TONGXIANG YUESHUN WRAP KNITTING

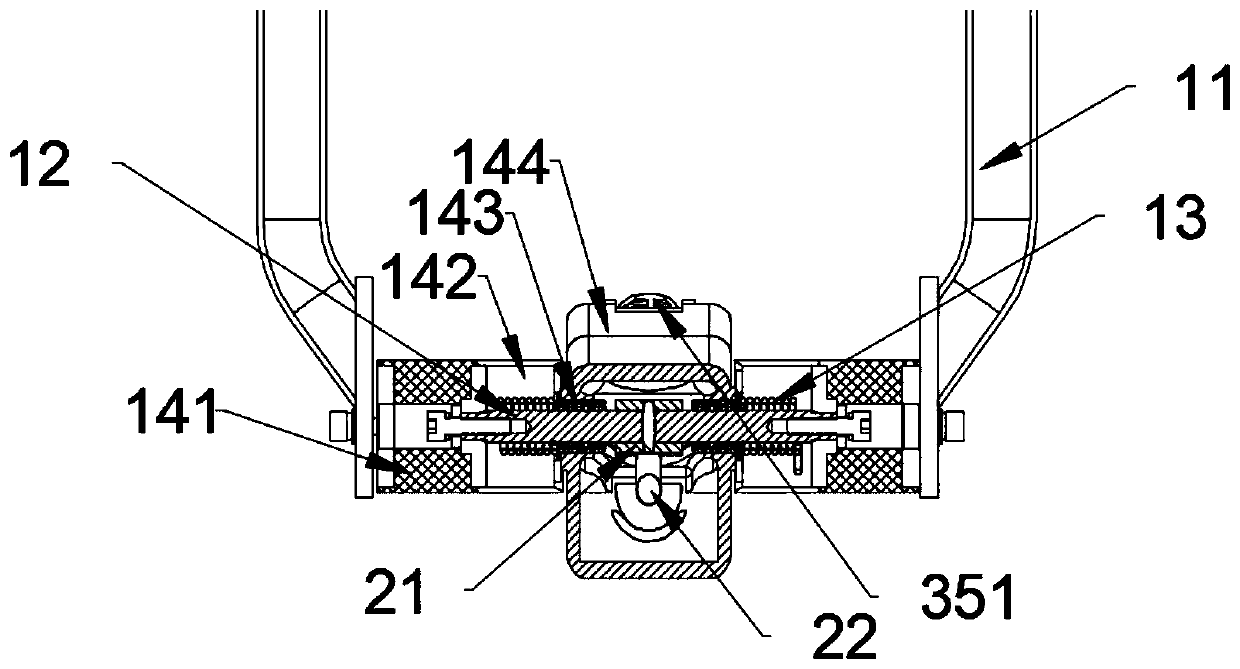

Plate compactor reversing control mechanism and plate compactor

PendingCN109750654AIncreased durabilityExtend the lifespanSoil preservationHuman mechanicsFixed position

The invention provides a plate compactor reversing control mechanism and a plate compactor. The plate compactor reversing control mechanism comprises a reversing handle, a rotary crankshaft, a positioning spring, a linkage crank and a top end shell, the reversing handle is connected with the rotating crankshaft, the rotating crankshaft is connected with the linkage crank, and the positioning spring is used for resetting the reversing handle. The plate compactor reversing control mechanism has higher durability, the service life of the plate compactor reversing control mechanism is effectivelyprolonged, and production waste caused by frequent replacement of the plate compactor reversing control mechanism is reduced. The mechanism is provided with the positioning spring, under the conditionthat the reversing handle is not influenced by external force, the reversing handle can be fixedly rotated and kept at a fixed position through the positioning spring, the plate compactor has a better standby state through the structure, the operation difficulty of the plate compactor is reduced, the application environment of the plate compactor is improved, the plate compactor conforms to the design of human mechanics, and the use efficiency of an operator on the plate compactor is greatly improved.

Owner:B D X MACHINERY LTD

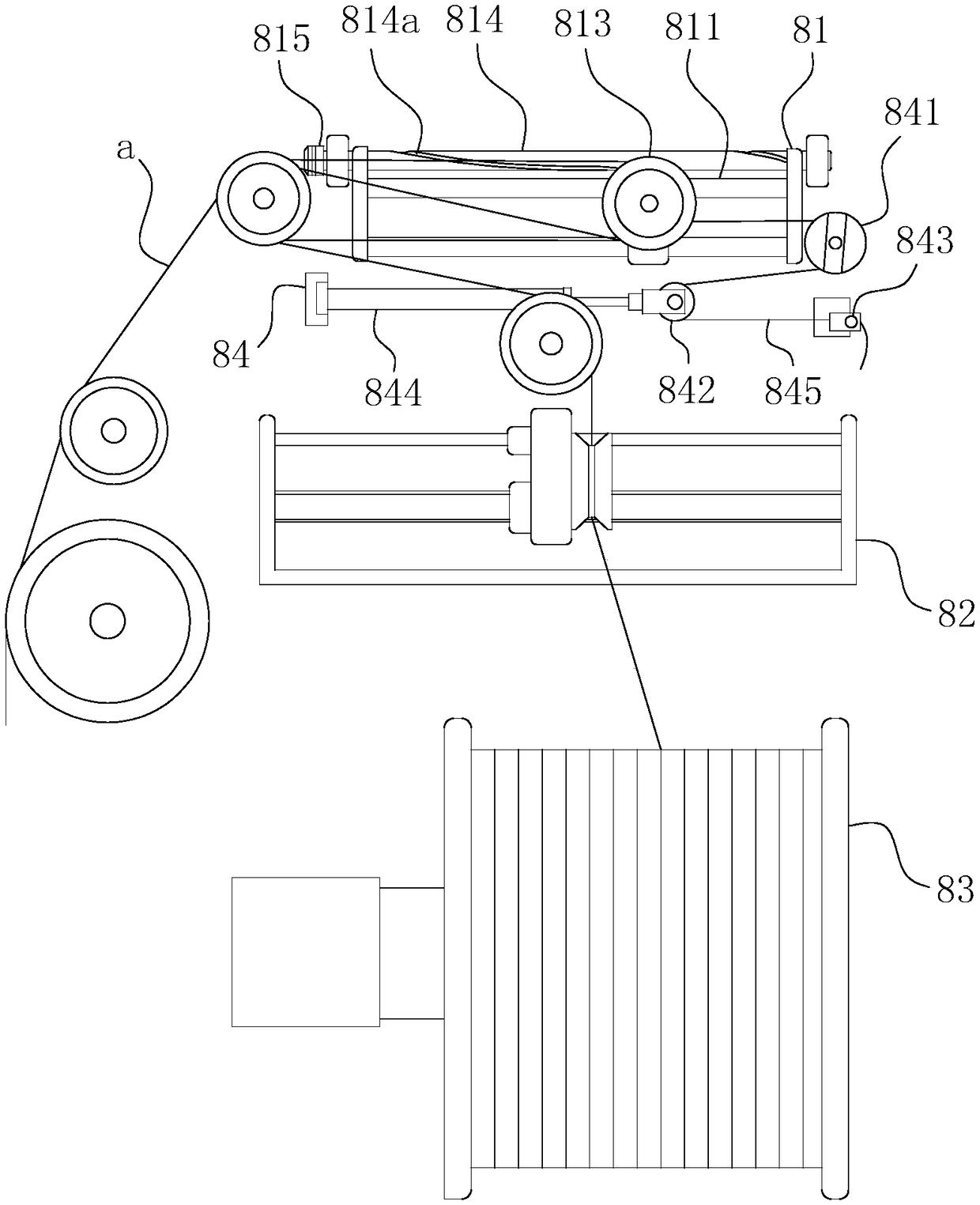

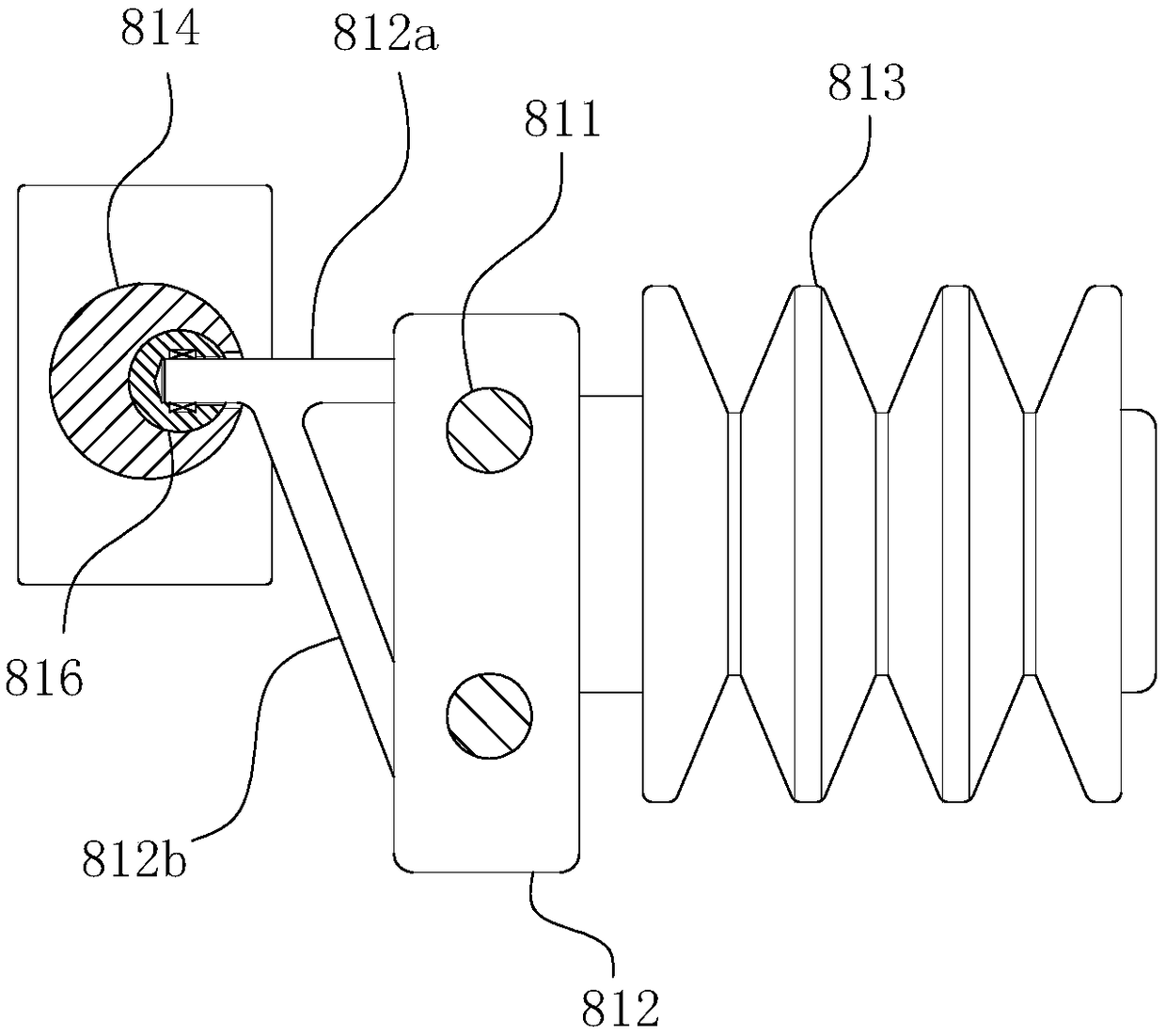

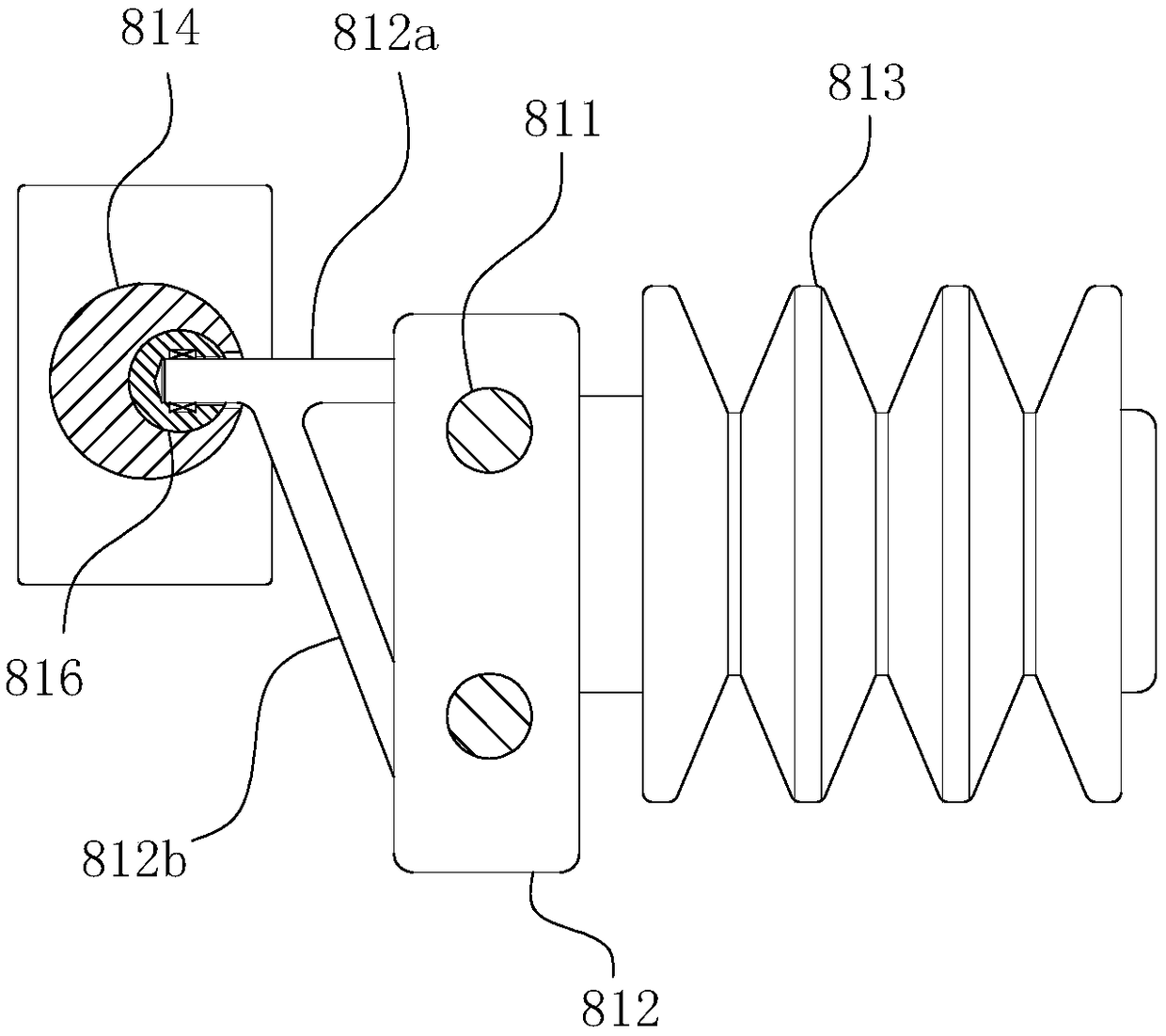

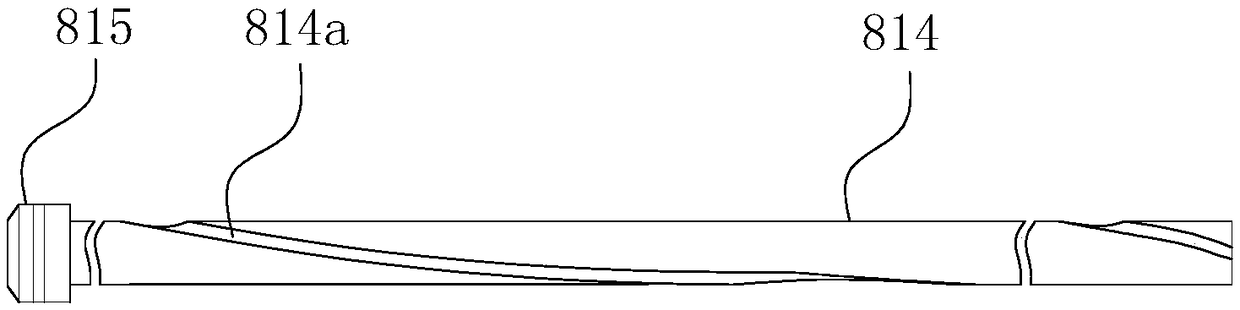

Winding displacement device for wire drawing machine

The invention belongs to the technical field of production of enameled wires, and specifically relates to a winding displacement device for a wire drawing machine. The device provided by the inventioncomprises a tension control assembly, a winding displacement assembly and a wire collection reel, wherein the tension control assembly comprises horizontal sliding guide rails, a guiding block, a swing wheel and a driven rotating rod; a spiral groove surrounds the axis of the driven rotating rod and is located at the position of the rod body of the driven rotating rod; the guiding block is provided with a push arm extending toward the spiral groove; the extending part of the push arm extends into the groove chamber of the spiral groove, so the push arm can push the driven rotating rod to revolve along the axis of the driven rotating rod due to the spiral groove when the guiding block slides to move along the horizontal sliding rails; and a rotating switch used for monitoring the rotatingrange of the driven rotating rod is arranged at the rod end of the driven rotating rod. The device provided by the invention has ingenious, compact and reasonable structure, is quick and flexible to steer off, has low operation noise, can effectively solve the problems of short service life and poor sensitivity of a traditional proximity switch, and has strong practicability.

Owner:TONGLING JINGXUN SPECIAL ENAMELLED WIRE

Flat car structure

The invention relates to a flat car structure. The flat car structure comprises two parallel flat car guide rails and a car body capable of moving on the flat car guide rails; limiting blocks are installed at the two ends of each flat car guide rail, a driving wheel set and a driven wheel set are installed at the bottom of the car body, wheels of the driving wheel set and the driven wheel set are all located on the flat car guide rails, a pneumatic motor is fixedly installed on the abdomen of the car body, a reduction box is installed at the output end of the pneumatic motor, and the output end of the reduction box is connected with a driving shaft of the driving wheel set; and an air actuated control system is further included, the air actuated control system comprises a coiling block, an air supply pipe and mechanical valves installed at the two ends of the bottom of the car body, a hand-operated direction valve is further fixedly installed on the car body, the air supply pipe is wound around the coiling block, and the air supply pipe is sequentially connected with the hand-operated direction valve, the mechanical valve at one end of the car body, the pneumatic motor and the mechanical valve at the other end of the car body. In the flat car running period, the power using hidden danger is avoided, the safety stage is high, and positioning is accurate.

Owner:张红伟

Thread trimming and presser foot lifting device for sewing machine

ActiveCN109487454BWide applicabilityMeet needsNeedle severing devicesSewing-machine control devicesElectric machineryEngineering

The invention provides a thread-cutting presser foot lifter for sewing machinery, belongs to the technical field of clothing manufacture equipment and solves the technical problems that, for instance,a thread-cutting presser foot lifter of existing sewing machinery has poor applicability. A screwing machine comprises a bottom plate, a presser foot rod arranged above the bottom plate and a presserfoot fixedly connected to the lower end of the presser foot rod; a thread cutting mechanism is also arranged right below the presser foot at the bottom of the bottom plate. The thread-cutting presserfoot lifter comprises a driving motor fixed to the bottom of the bottom plate and having two output shafts; the output shaft at one end of the driving motor is fixedly connected with a presser foot lift cam; a linkage is arranged above the bottom plate; the presser foot lift cam can drive the presser foot rod to rise through the linkage; the output shaft at the other end of the driving motor is fixedly connected with a thread-cutting cam; the thread-cutting cam can drive the thread cutting mechanism to do cutting motion. The thread-cutting presser foot lifter herein is widely applicable and reliable in performance.

Owner:ANHUI JIEYU SHOEMAKING MACHINERY TECH CO LTD

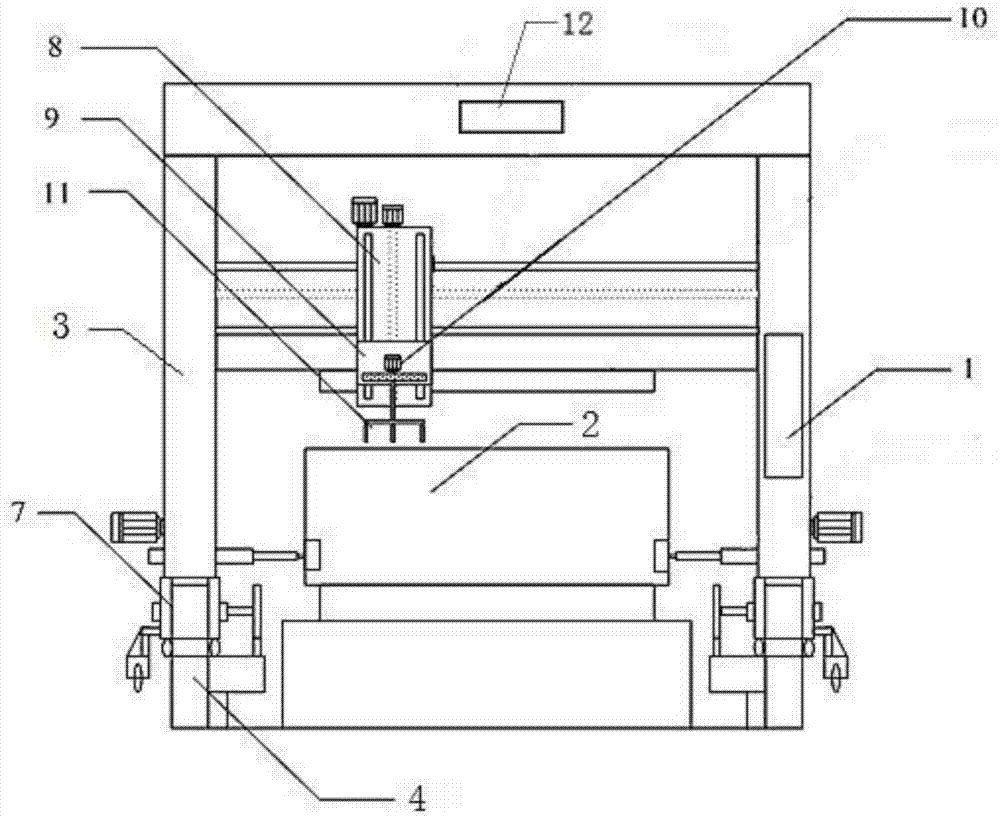

A device and method for laying reinforcing fiber filaments for the production of composite grids

The invention discloses a reinforced fiber silk laying device and method used for producing a grating made of a composite material. The device comprises a die table, rails are laid on the two sides of the die table, a gantry type frame stretches over the die table, and running wheels are arranged at the bottom of the gantry type frame. The gantry type frame is driven to move along the rails through the running wheels, and the gantry type frame is provided with a computer control system, a sliding table mechanism and a silk supply mechanism. The sliding table mechanism is provided with a lifting table mechanism. The lifting table mechanism is provided with a rotary table mechanism. A work head is laid on the rotary table mechanism. The computer control system is connected with the running wheels, the sliding table mechanism, the lifting table mechanism, the rotary table mechanism and the silk supply mechanism. According to the method, the device is used for achieving reinforced fiber laying work on the die worktable. By means of the device and method, the process mode that reinforced fiber laying is completed manually is changed, flexible reversing of laying of multiple sets of fiber silk can be completed, and production requirements of rectangular grating die tables in different sizes are met.

Owner:南京申瑞电力电子有限公司

Quick-drill pneumatic hard rock drill

ActiveCN102900355BHigh shear forceIncrease propulsionConstructionsReciprocating drilling machinesEngineeringAtmospheric pressure

The invention discloses a quick-drill pneumatic hard rock drill which comprises a host machine, an operating valve and a propulsion unit, which are independent of one another and are connected with one another. An air suction nozzle communicated with an air distribution valve is arranged on a base of the host machine; the air distribution valve is in a fin type structure and consists of a valve body, a valve block and a valve rod; a valve cavity is arranged inside the valve body and is respectively communicated with a front chamber and a back chamber of a cylinder body through left and right air passages; the seesaw-like valve block is installed in the valve cavity through the valve rod; under the action of air pressure, the two ends of the valve block can respectively close or open the left and right air passages to enable a piston rod to move with high frequency; and a rotating device is arranged on a machine head. According to the invention, a new fin type air distribution valve which is flexible in change-over is adopted, so the impact frequency is greatly improved. The rotating device realizes primary transmission by adopting worm-and-gear principle, the transmission ratio is big, and the transmission efficiency is high. The quick-drill pneumatic hard rock drill is small in size, light in weight and convenient to operate, and is applicable for various propulsion modes.

Owner:青岛达邦钻机有限责任公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com