Flat car structure

A flat car and car body technology, applied in the field of flat cars, can solve the problems of combustible gas explosion, lack of safety, spark generation, etc., and achieve the effect of high safety factor, avoiding electric shock and hurting people, and good reliability in use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

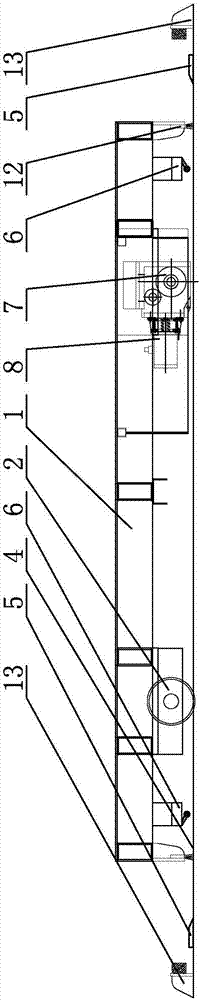

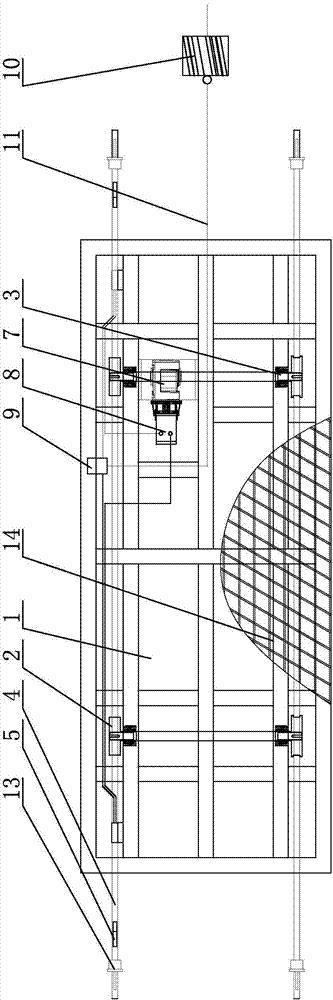

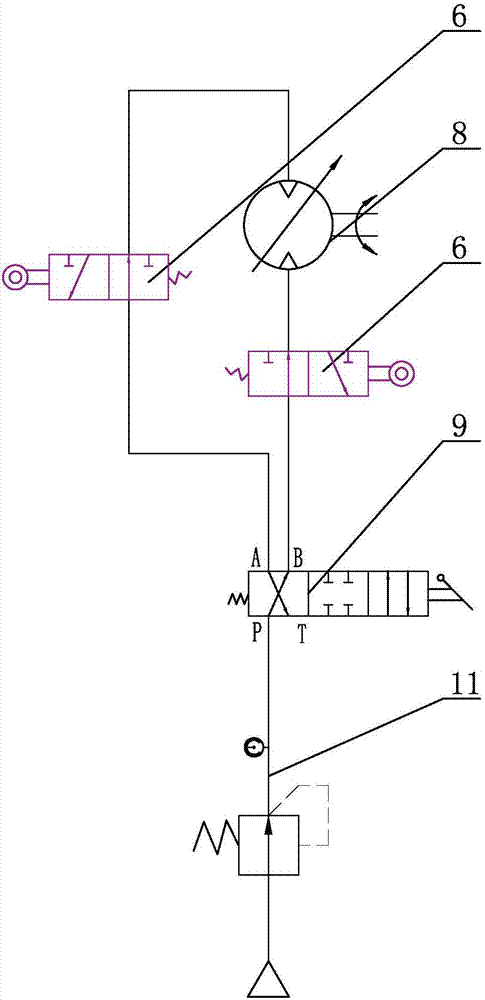

[0025] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

[0026] Such as figure 1 , figure 2 and image 3 As shown, the flat car structure of this embodiment includes two flat car guide rails 4 installed in parallel, limit blocks 5 are respectively installed at both ends of the flat car guide rails 4, and the car body 1 that can move on the flat car guide rails 4 The bottom of the car body 1 is respectively equipped with a driving wheel group 3 and a driven wheel group 2, the wheels of the driving wheel group 3 and the driven wheel group 2 are all located on the flat car guide rail 4, and an air motor 8 is fixedly installed on the abdomen of the car body 1 , the output end of the air motor 8 is equipped with a reducer 7, and the output end of the reducer 7 is connected to the driving shaft of the driving wheel group 3; it also includes a pneumatic control system, which includes a reel 10, an a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com