Novel derrick climber

A climbing device and derrick technology, applied in the field of robotics, can solve problems such as time-consuming, difficult to find, and low work safety factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

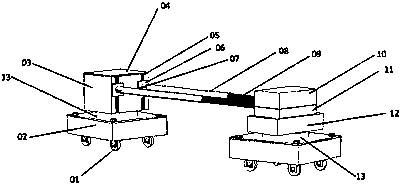

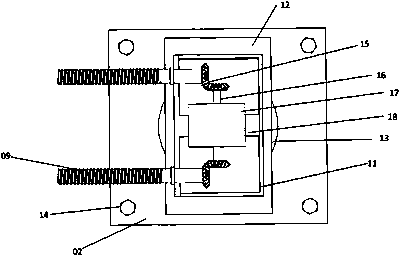

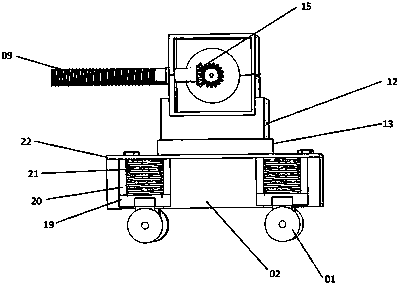

[0023] see figure 1 , 2 , 3, 4, a new type of derrick climber, consisting of 01 universal wheel, 02 electromagnet block, 03 power storage box, 04 power storage box cover, 05 arm adjustment chute, 06 adjustment slider, 07 arm Rod connection frame, 08 crawling rear arm, 09 crawling forearm, 10 upper cover of transmission box, 11 transmission box, 12 circuit control box, 13 motor turntable, 14 cover bolt, 15 bevel gear, 16 motor drive shaft, 17 double-headed motor , 18 motor fixing frame, 19 universal wheel lifting slider, 20 storage hole, 21 compression spring, 22 cover plate, 23 universal wheel lifting chute.

[0024] Its climbing process is as Figure 5 As shown, initially, the electromagnet blocks 02 at both ends of the climber are adsorbed on the column surface of the derrick leg. At this time, the universal wheel 01 is under the action of the e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com