Reversing switch of electric tool

A technology of electric tools and reversing switches, which is applied in the direction of electric switches, circuits, electrical components, etc., can solve the problems of difficult assembly of reversing switches, low reliability of switches, high defect rate, etc., achieve low cost, improve reliability, and contact good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

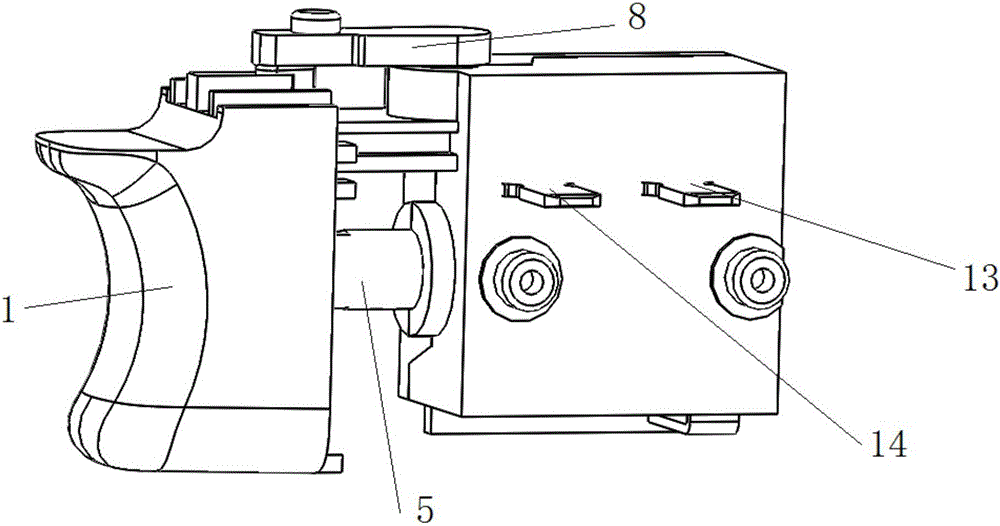

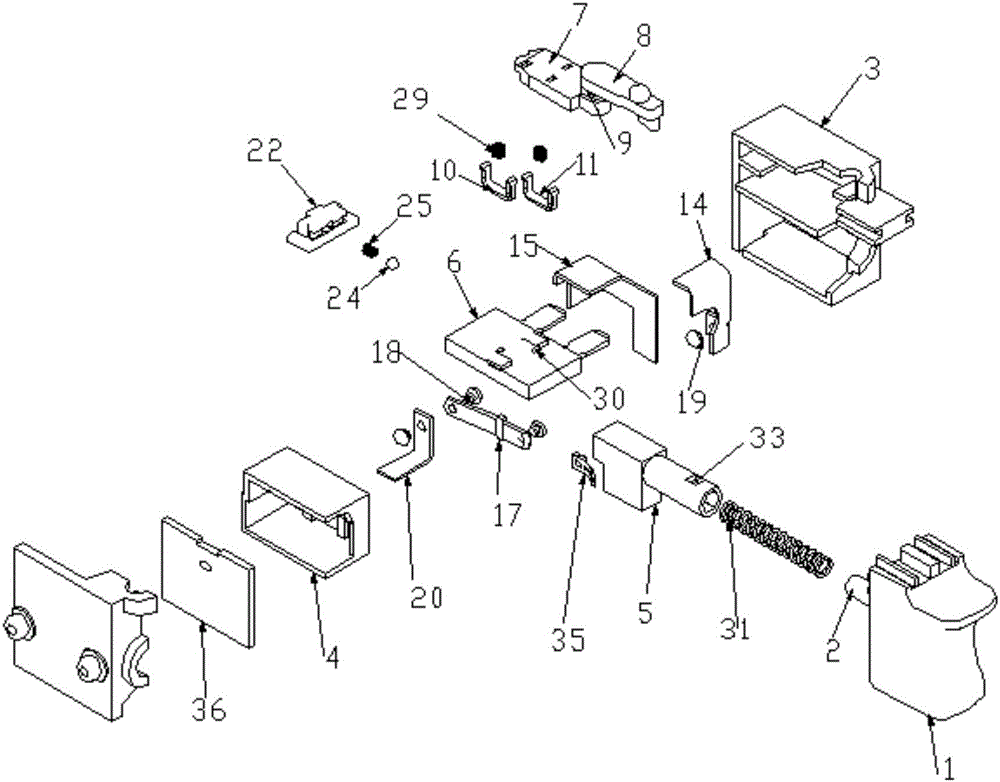

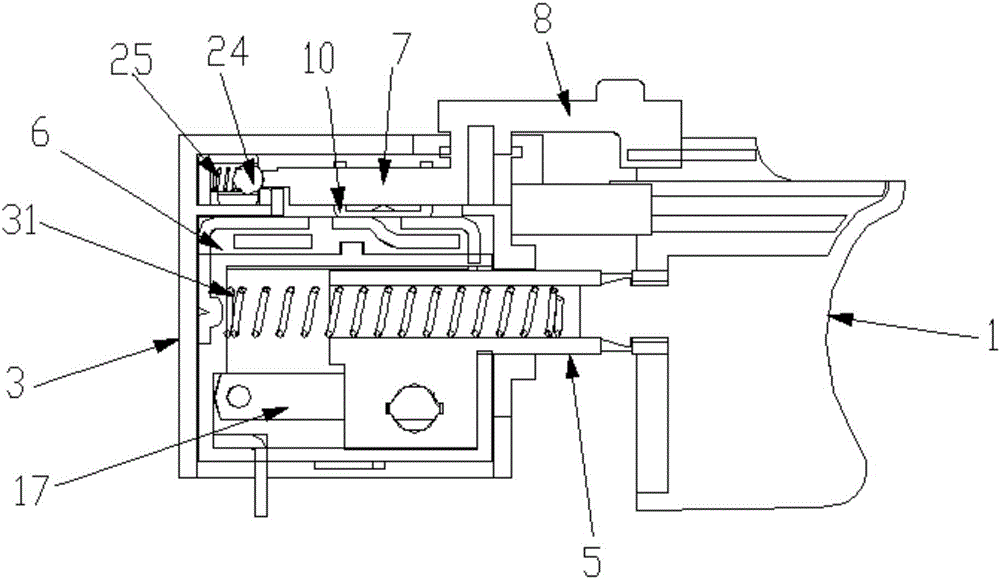

[0034] Such as Figure 1-9 As shown, the reversing switch of the electric tool includes a button 1, a base 3, an inner base 4 located below the base 3, a push rod 5 arranged in the inner base 4 connected to the button 1, and the inner base 4, the reversing base 6 above the base 3, the reversing handle 7 arranged inside the base 3 and above the reversing base 6, the shifting rod 8 arranged outside the base 3, connecting the reversing shifting handle 7 and the shifting rod 8, the first reversing movable contact piece 10 and the second reversing movable contact piece 11 clamped on the reversing toggle handle 7, it is characterized in that, the reversing base 6 is provided with an end extension The first terminal 12 and the second terminal 13 of the base 3, the other end of the first terminal 12 and the other two ends of the second terminal 13 are in the reversing base 6, and the first terminal 12 The other end is located in the middle of the other two ends of the second terminal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com